Circuit Description

UMSITRPDS3-1

November

2010

8-2

8.1 OVERALL OPERATION

The measuring cell sensor (1) detects the applied process pressure. The sensor’s analog output signal is

amplified by an instrument amplifier (2) and converted into a digital signal in an analog-digital converter

(3). This data is evaluated by a microcontroller (4) that corrects the signal and temperature characteristics.

Microcontroller output is converted to a 4-20 mA output current by the digital-analog converter (5).

A diode circuit (10) provides reverse polarity protection in the event of reversed loop connections. An

external digital milliammeter can be connected across the diode. The diode and the electronics discussed

in the previous paragraph are housed in an assembly named the electronics module.

Measuring cell-specific data (e.g. measuring range, measuring cell material, oil fill) are stored in a non-

volatile memory (6) located in the measuring cell assembly. Transmitter configuration data (e.g. turn-

down, electric damping) are stored in a second non-volatile memory (6) in the electronics module.

The transmitter can be configured locally using three built-in magnetic pushbuttons (8) or remotely, via

the HART modem (7), using the HART Communicator. The digital display (9) shows input pressure,

output current, error messages, modes of operation, or other data as determined by the configuration and

by user commands via the magnetic pushbuttons or HART Communicator.

In the following sections, individual measuring cell types will be explained.

8.2 PRESSURE

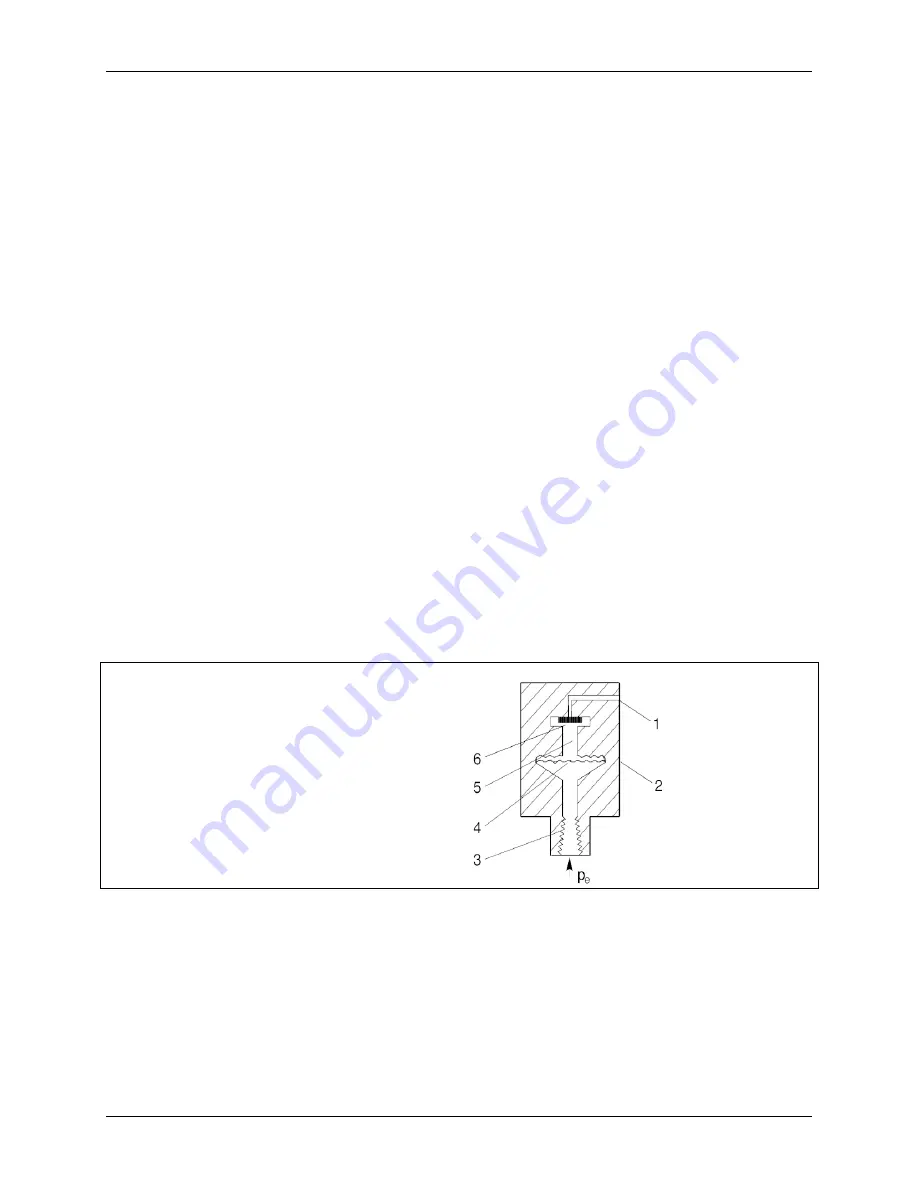

As shown in Figure 8-2, process pressure p

e

is applied to the measuring cell (2) through the process

connection (3). This pressure is applied to the seal diaphragm which flexes to transfer the pressure to the

fill fluid (5) which in turn transfers the pressure to the silicon pressure sensor (6).

1

2

3

4

5

6

p

e

Reference pressure

Measuring cell

Process connection

Seal diaphragm

Filling fluid

Silicon pressure sensor

Input variable pressure

FIGURE 8-2 Pressure Measuring Cell

The silicon pressure sensor consists of four piezo-resistors in a bridge circuit. The bridge is located on the

measuring diaphragm. Applied pressure causes a change in bridge resistance that is proportion to the

input pressure.

A transmitter with a measuring span of up to 925 psi will measure the input pressure compared to

atmospheric pressure. A transmitter with a measuring span of 2320 psi (or greater) compares input

pressure to a vacuum.

Summary of Contents for 7MF4033 series

Page 48: ...Model 275 Universal Hart Communicator UMSITRPDS3 1 November 2010 2 26 ...

Page 86: ...Installation UMSITRPDS3 1 November 2010 4 34 ...

Page 152: ...Calibration and Maintenance UMSITRPSD3 1 November 2010 7 20 ...

Page 158: ...Circuit Description UMSITRPDS3 1 November 2010 8 6 ...

Page 197: ......

Page 198: ......

Page 200: ...Model Designations and Specifications UMSITRPDS3 1 November 2010 9 42 ...

Page 204: ...Glossary UMSITRPDS3 1 November 2010 10 4 ...

Page 208: ...Appendix A Online Configuration Map UMSITRPDS3 1 11 4 November 2010 ...

Page 216: ...Appendix C Elevation and Suppression Correction UMSITRPDS3 1 13 4 November 2010 ...