Model Designations and Specifications

UMSITRPDS3-1

November

2010

9-10

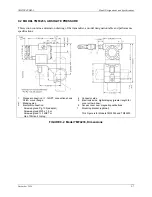

TABLE 9-4 Model 7MF4233, Specifications

Input

Measured variable

Absolute pressure (gage construction)

Span (infinitely adjustable)

Span

Max. permissible test pressure

8.3 to 250 mbar a (0.12 to 3.6 psi a) see Note

6 bar a (87 psi a)

43 to 1300 mbar a (0.62 to 18.9 psi a)

10 bar a (145 psi a)

160 to 5000 mbar a (2.32 to 72.5 psi a)

30 bar a (435 psi a)

1 to 30 bar a (14.5 to 435 psi a)

100 bar a (1450 psi a)

Lower measuring limit

• Measuring cell, silicone oil filling

0 mbar a (0 psi a)

Upper measuring limit

100% of maximum span

Output

Output signal

4 to 20 mA

• Lower limit (infinitely adjustable)

3.55 mA, factory preset to 3.84 mA

• Upper limit (infinitely adjustable)

23 mA, factory preset to 20.5 mA or optionally set to 22.0 mA

Load

• Without HART communication

R

B

≤

(U

H

– 10.5 V)/0.023 A in

Ω

; U

H

: power supply in V

• With Hart communication

R

B

= 230 to 500

Ω

(SIMATIC PDM) or

R

B

= 230 to 1100

Ω

(HART Communicator)

Accuracy

To EN 60770-1

Reference Conditions

Increasing characteristic, start of scale value 0 bar, stainless steel seal diaphragm,

silicon oil filling, temperature 25°C (77°F) r: span ratio (r = max. span/set span)

Error in measurement and fixed-point

setting (including hysteresis and

repeatability)

• Linear characteristic

- r

≤

10

≤

0.1%

- 10

≤

r < 30

≤

0.2%

Long-term drift (temperature change

+/-30°C (+/-54°F))

≤

(0.1 * r)%/year

Influence of ambient temperature

• at -10 to +60°C (14 to +140°F)

≤

(0.1 * r + 0.2)%

• at -40 to -10°C and +60 to +85°C (-40

to +14°F and 140 to +185°F)

≤

(0.1 * r + 0.15)%/10K

Rated operating conditions

Degree of protection (to EN 60529)

IP65

Process temperature

• Measuring cell, silicon oil filling

-40 to +100°C (-40 to +212°F)

• Measuring cell, inert filling liquid

-20 to +100°C (-4 to +212°F)

• In conjunction with dust explosion

protection

-20 to +60°C (-4 to +140°F)

Ambient conditions

• Ambient temperature, digital indicators -30 to +85°C (-22 to +185°F)

• Storage temperature

-50 to +85°C (-58 to +185°F)

• Climatic class, condensation Permissible

• Electromagnet compatibility

To EN 61326 and NAMUR NE 21

Design

Weight, approximate, without options

1.5 kg (3.3 lb)

Housing material

Low copper die-cast aluminum, GD-AISi 12 or stainless steel precision casing, mat.

No. 1.4408

Wetted parts materials

• Connection shank

Stainless steel, mat. No. 1.4404/316L or Hastelloy C4, mat. No. 2.4610

• Oval flange

Stainless steel, mat. No. 1.4404/316L

• Seal diaphragm

Stainless steel, mat. No. 1.4404/316L or Hastelloy C276, mat. No. 2.4819

Summary of Contents for 7MF4033 series

Page 48: ...Model 275 Universal Hart Communicator UMSITRPDS3 1 November 2010 2 26 ...

Page 86: ...Installation UMSITRPDS3 1 November 2010 4 34 ...

Page 152: ...Calibration and Maintenance UMSITRPSD3 1 November 2010 7 20 ...

Page 158: ...Circuit Description UMSITRPDS3 1 November 2010 8 6 ...

Page 197: ......

Page 198: ......

Page 200: ...Model Designations and Specifications UMSITRPDS3 1 November 2010 9 42 ...

Page 204: ...Glossary UMSITRPDS3 1 November 2010 10 4 ...

Page 208: ...Appendix A Online Configuration Map UMSITRPDS3 1 11 4 November 2010 ...

Page 216: ...Appendix C Elevation and Suppression Correction UMSITRPDS3 1 13 4 November 2010 ...