861-9601.9 • INSTALLATION AND OPERATING INSTRUCTIONS • 8DA10 • Revision 11

203/214

Servicing

Servicing

41

Maintenance

Under normal operating conditions, the fixed-mounted circuit-breaker switchgear 8DA10 and

the vacuum circuit-breaker 3AH49 are maintenance-free.

Inspection/testing of the secondary equipment such as the capacitive voltage detecting

system is done within the scope of national standards and customer-specific regulations.

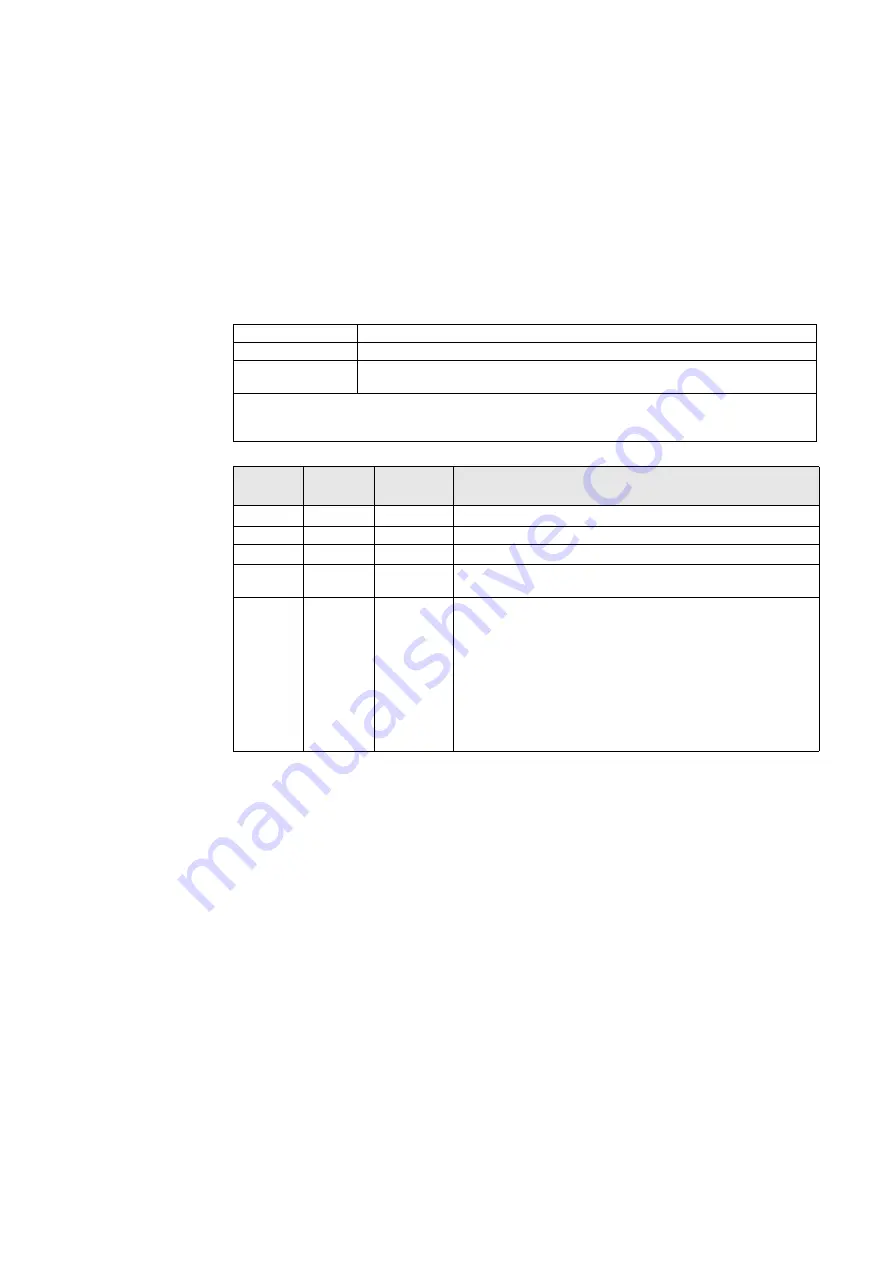

The switchgear should be inspected at the following intervals:

Maintenance

recommendation

Visual check

every 5 years

Status inspection

every 10 years

Maintenance

after 10000 operating cycles of the circuit-breaker

(see page 204, "Maintenance of the vacuum circuit-breaker operating mechanism")

These intervals are guidelines which have to be adjusted to the different operating conditions

(e.g. dusty environment, frequent condensation, etc.). The maintenance actions with the associated test and

maintenance operations are shown in the following table.

Visual

inspection

Status

inspection

Maintenance

X

X

X

Check and document SF

6

gas pressure (see page 35, "Insulating gas")

X

X

Check and document dew-point (humidity content) ( ≤ -15 °C)

X

X

Check and document gas quality (air content) (SF

6

share ≥ 95 %)

X

Check operating mechanism and interlocking of disconnector and

earthing switch (if required, grease linkage and bearings)

X

In all gas compartments, if gas has to be exchanged or upon

reaching the number of operating cycles:

➭ Evacuate SF

6

gas.

➭ Replace desiccant bags.

➭ Replace toroidal sealing rings.

➭ Fill in SF

6

gas.

➭ Check and document gas pressure.

➭ Check tightness.