43 / 92

Siemens

Actuators SAX.., SAY.., SAV.., SAL.. for valves

CE1P4040en

Building Technologies

Handling

2018-12-05

First, observe "Special notes on mounting” (page 36).

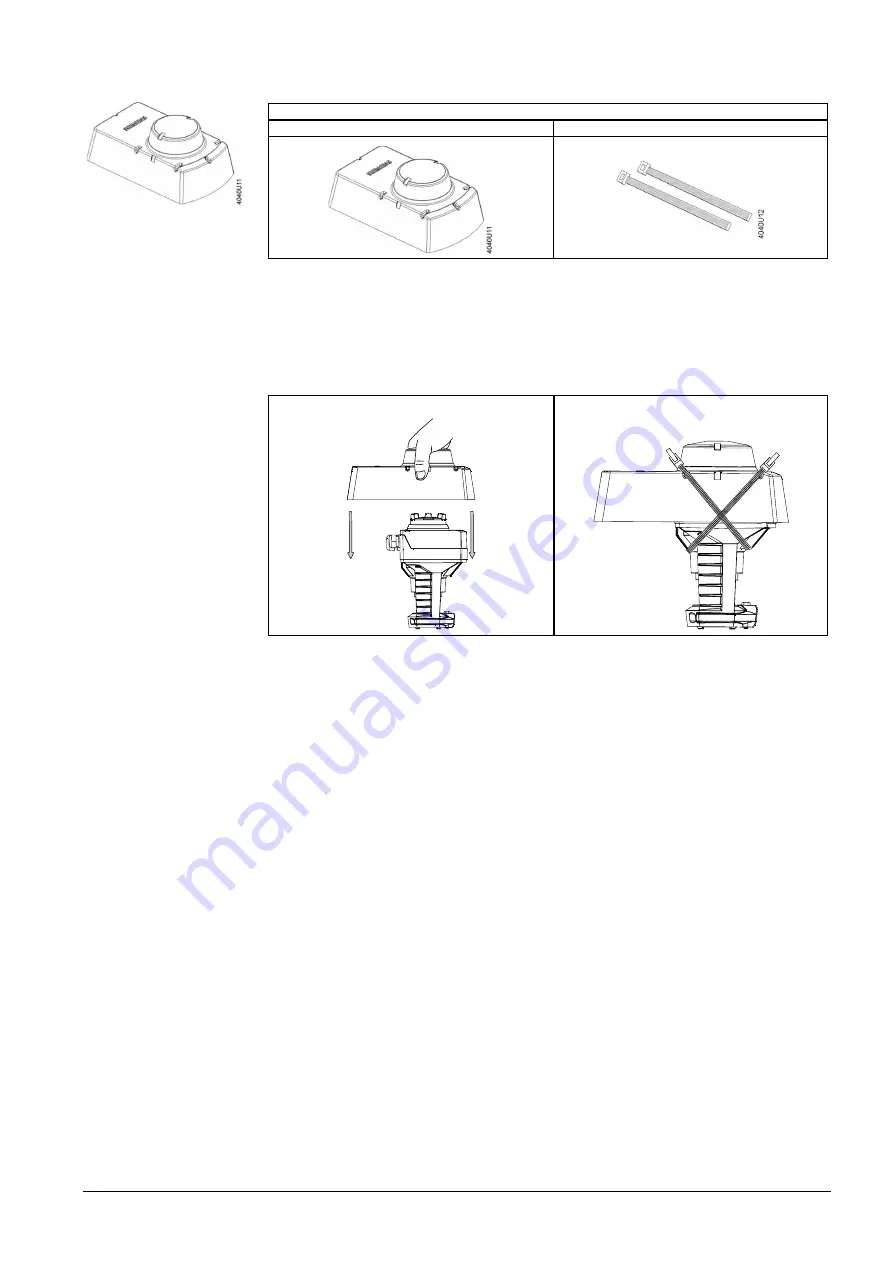

Scope of delivery

Weather shield ASK39.1

2 UV

-

proof cable ties

·

To protect the actuator when used outdoors, the weather shield must always be

fitted.

·

If fitted several times, 2 UV-proof cable ties (800 x 4 mm) must be used.

·

The manual adjuster cannot be used when the weather shield is mounted.

·

SAX61../MO is not suitable for outdoor applications.

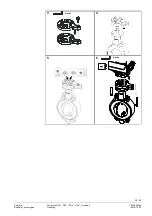

1

2

4040J

30a

40

4

0J

3

1a

Weather shield

ASK39.1

Notes