67 / 92

Siemens

Actuators SAX.., SAY.., SAV.., SAL.. for valves

CE1P4040en

Building Technologies

Functions and control

2018-12-05

4.13 Communicating actuators Modbus RTU

4.13.1 Detection of valve seat

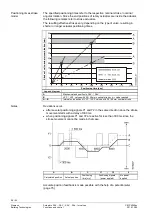

The actuators feature force-dependent valve seat detection. After calibration, the

exact valve stroke is filed in the actuator’s memory. When the actuator reaches the

respective end of stroke, it does not hit the valve’s seat at full speed, but stops for 5

seconds at about 1% before the stored position is reached. If the positioning signal

stays at 0% or 100%, the actuator travels to the calculated end position at reduced

positioning speed and builds up the required nominal force.

This function extends the actuator’s service life since the dynamic forces are

reduced when approaching the valve seat and there will be less strain on the gear

train.

In addition, the actuator’s oscillations in the case of instable control are

suppressed.

If no force is built up in the calculated end position (e.g. in the event of temperature

effects for instance), the actuator continues to operate at a reduced positioning

speed until the nominal positioning force is restored. This ensures that the valve

always fully closes.

After a power failure, valve seat identification is not active – the actuators without

fail safe function define their stroke position upon return of power at 50% and

automatically set their internal setpoint in register 1 to the startup setpoint (register

516). The actuator closes at this setting. There is a short-term deviation between

the setpoint and the internal stroke position.

When the valve plug reaches each seat for the first time, the actuator readjusts its

stroke mode.

Setpoint prior to power outage 35%, no manual adjustment during the power

outage. Internal stroke position value after return of power 50%. Internal setpoint

after return of power equal to startup setpoint (register 516, here 0%). The actuator

moves 35% in the direction of "Retract actuator stem" and reaches the valve seat

(if the setpoint has not been changed in the meantime). The internal stroke position

is set to 0%.

The actuator now follows the changed valve stroke position effective immediately.

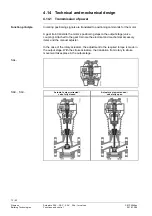

4.13.2 Detection of foreign bodies

The actuator detects when the valve is clogged and adjusts its operational

behavior accordingly to prevent damage to itself or the valve.

If the actuator hits an obstacle within the calibrated stroke and is not able to

overcome it with its nominal positioning force, it stores the position at which the

obstacle was hit. Depending on the direction of travel, as …

·

"Lower limit of valve clogging", if the clogging was detected when

traveling in the direction of "Actuator’s stem retracting".

·

"Upper limit of valve clogging", if the clogging was detected when

traveling in the direction of "Actuator’s stem extending".

Now, the actuator status LED blinks green and the actuator only follows the

positioning signal between the positions "Actuator’s stem retracted" and "Upper

limit of valve clogging" or "Actuator’s stem extended" and "Lower limit of valve

clogging".

After detection of clogging, 3 attempts are made to overcome clogging by traveling

about 15% in the opposite direction and then trying again to overcome the position

of clogging. If the attempts made are unsuccessful, the actuator continues to follow

Example