32/258

Siemens Switzerland Ltd

User manual RVS61.843, RVS41.813

CE1U2355en_02

HVAC Products

3 Mounting and installation

28. September 2009

2359

Z

53

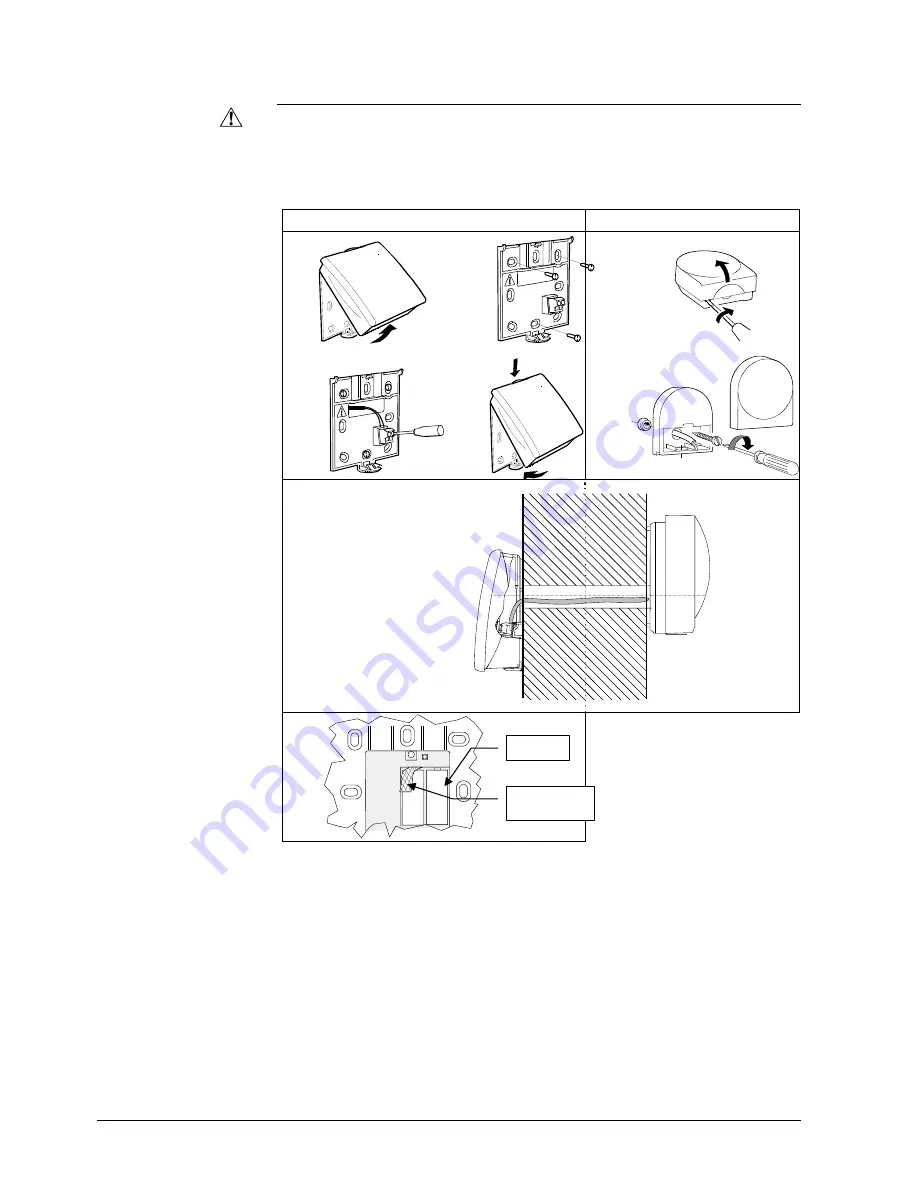

3.8.3 Wireless outside sensor AVS13.399

•

The radio transmitter must be installed inside the building.

•

The radio transmitter’s mounting location should be chosen such that batteries

can be easily changed

Mounting method

RF transmitter

Outside sensor

The outside sensor is to be connected to the radio transmitter via a 2-core cable, the

connections are interchangeable.

The device is powered by two 1.5 V alkaline batteries type AAA (LR03).

Connections

23

59

Z

5

4

2359Z30

2359Z33

23

59

Z5

9

2359Z3

1

235

9Z55

AA

A

AA

A

Removing the

battery transit tab

Battery

2359Z

32