Summary of Contents for Arcteq AQ01

Page 1: ...INSTRUCTION MANUAL AQ101 AQ101D AQ110P AQ01 ...

Page 44: ...Instruction manual AQ101 AQ101D AQ110P AQ01 44 48 ...

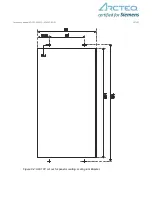

Page 45: ...Instruction manual AQ101 AQ101D AQ110P AQ01 45 48 ...

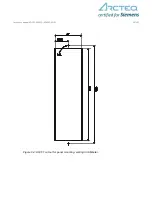

Page 46: ...Instruction manual AQ101 AQ101D AQ110P AQ01 46 48 9 2 AX001 CONNECTION FIBER ...

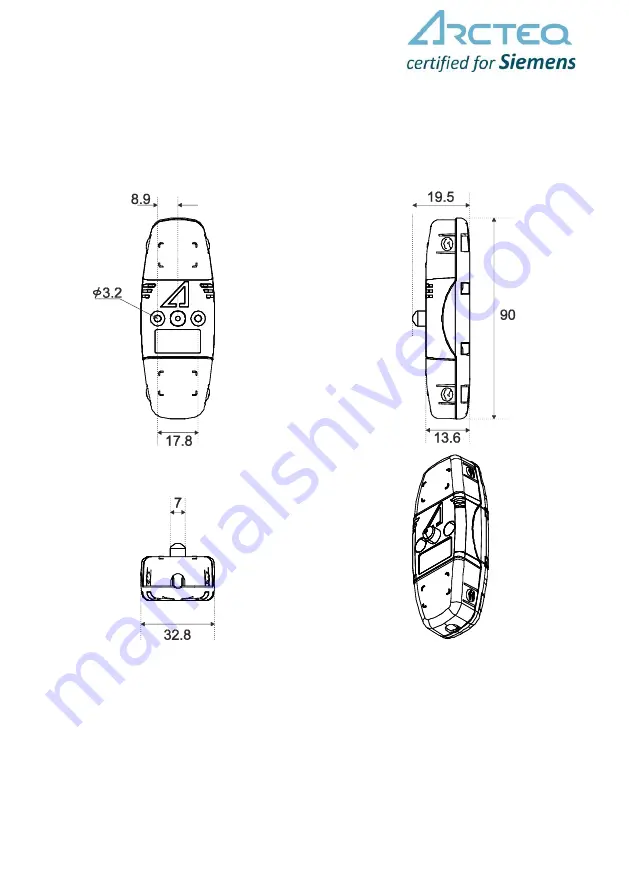

Page 47: ...Instruction manual AQ101 AQ101D AQ110P AQ01 47 48 9 3 AQ01 ARC FLASH SENSOR ...