17 / 26

Siemens

HMI-LED

CB1P3946en

Building Technologies

HMI-LED Programming

2013-08-19

4.3.2 Humidity display

The engineering unit of humidity displayed on the HMI-LED screen is “%RH”.

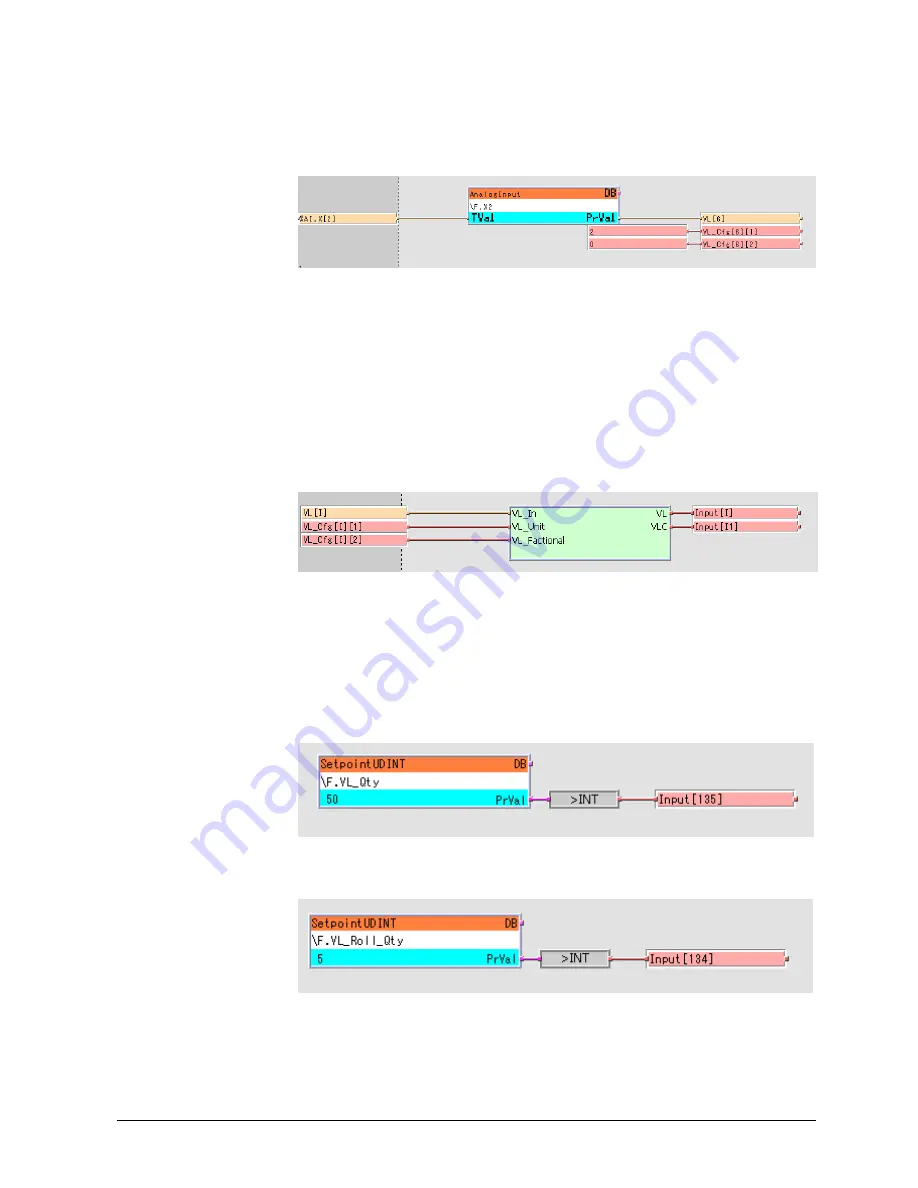

For example, for controller “X2” which connects to humidity sensor, there is a

humidity variable as below.

The humidity variable is sent to the Input register 6, and the “VL_Unit” need to be

defined as “2”. If the humidity variable is with one factional digital, the

“VL_Factional” should also be defined as “0”.

4.3.3 Input register

To show the value with exact engineering unit and factional digital, the Input

register should be defined in SAPRO.

For example, if the Input register 1 is defined as Boole variable, then the “VL_In”

needs to be converted from Boole to REAL, and the “VL_Unit” should be

configured as “0” as well as the “VL_Factional”.

Later the value will be transferred to the Input register 1, and the configuration will

be written to the Input register 51 as predefined.

4.3.4 Input register quantity

For different applications, the different quantity values can be displayed on the

HMI-LED screen.

The Input register quantity should be defined as “50” in the Input register 135.

Max. 5 values can be displayed alternately on the default page, which can be

defined by users as below.