Siemens Industry, Inc. 5300 Triangle Parkway, Norcross, GA 30092

A5E31166448A-006

Storage

Electrical control equipment which is to be stored prior

to its installation, should be checked before placing in

storage for possible damage during transit. It should

then be repacked and stored in a location which is

clean and dry.

When storage is in or near buildings under construc-

tion, provide covers to protect the equipment against

dust, moisture and falling objects.

Apparatus stored for long periods may cor

-

rode. Damage, while stored, will be minimized

by maintaining the best possible storage condi-

tions, and by periodically inspecting the equip-

ment and arresting the progress of corrosion and

other forms of deterioration which may be found.

A small amount of heat will stop corrosion that occurs

from moisture due to condensation.

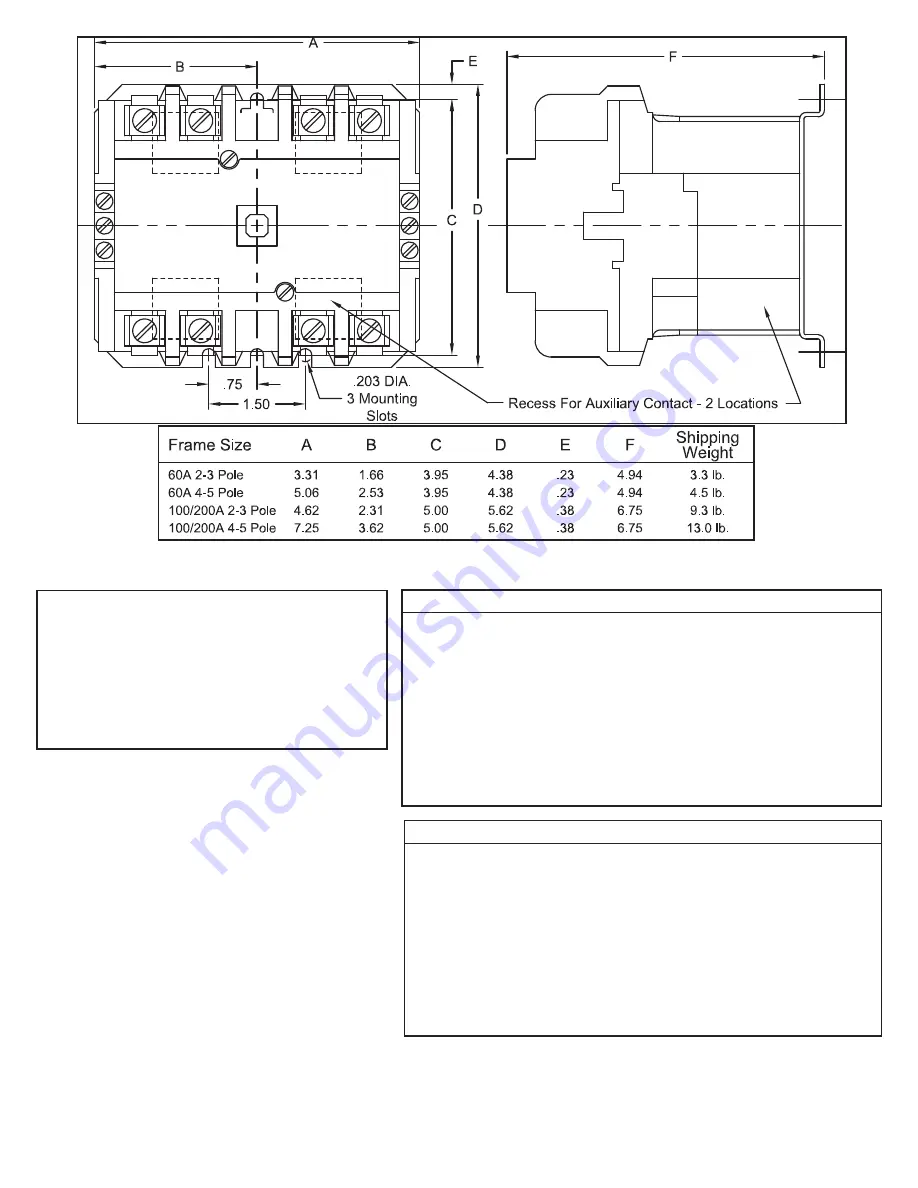

Fig. 6 Dimension Drawing 60, 100 and 200 Amp Device

CAUTION -

Coil must be wired correctly.

Risk of damage to the device.

All control wiring for contactor operation must only be made to

the coil isolation contact terminals #2, #3 and L2 terminal con-

nection points. Wiring made to any other terminal points will

burn out the coil and diode. If a coil burnout occurs, both the coil

and the diode must be replaced.

Table 6 - AC Operating Coils for 60 Ampere Contactors

Voltage

VAC

Freq.

Hz

Part Number

2-4 Pole 4-5 Pole

24

60 Hz

CLMD3C024

CLMD5C024

110/120

50/60 Hz

CLMD3C120

CLMD5C120

208

60 Hz

CLMD3C208

CLMD5C208

220/240

50/60 Hz

CLMD3C240

CLMD5C240

277

60 Hz

CLMD3C277

CLMD5C277

440/480

50/60 Hz

CLMD3C480

CLMD5C480

550/600

50/60 Hz

CLMD3C600

CLMD5C600

Table 7 - AC Operating Coils for 100 and 200 Ampere Contactors

Voltage

VAC

Freq.

Hz

Part Number

2-4 Pole 4-5 Pole

24

60 Hz

CLME3C024

CLME5C024

110/120

50/60 Hz

CLME3C120

CLME5C120

208

60 Hz

CLME3C208

CLME5C208

220/240

50/60 Hz

CLME3C240

CLME5C240

277

60 Hz

CLME3C277

CLME5C277

440/480

50/60 Hz

CLME3C480

CLME5C480

550/600

50/60 Hz

CLME3C600

CLME5C600