Compressor Compact

Adjustments

E382 EH81E 061 01 03 02

Siemens-Elema AB

39

Adjustments

Pressure regulator

• Open the compressor’s front cover to make

the pressure regulator accessible.

• Connect the test nozzle to the compressed

air outlet.

• Start the compressor with the on/off switch.

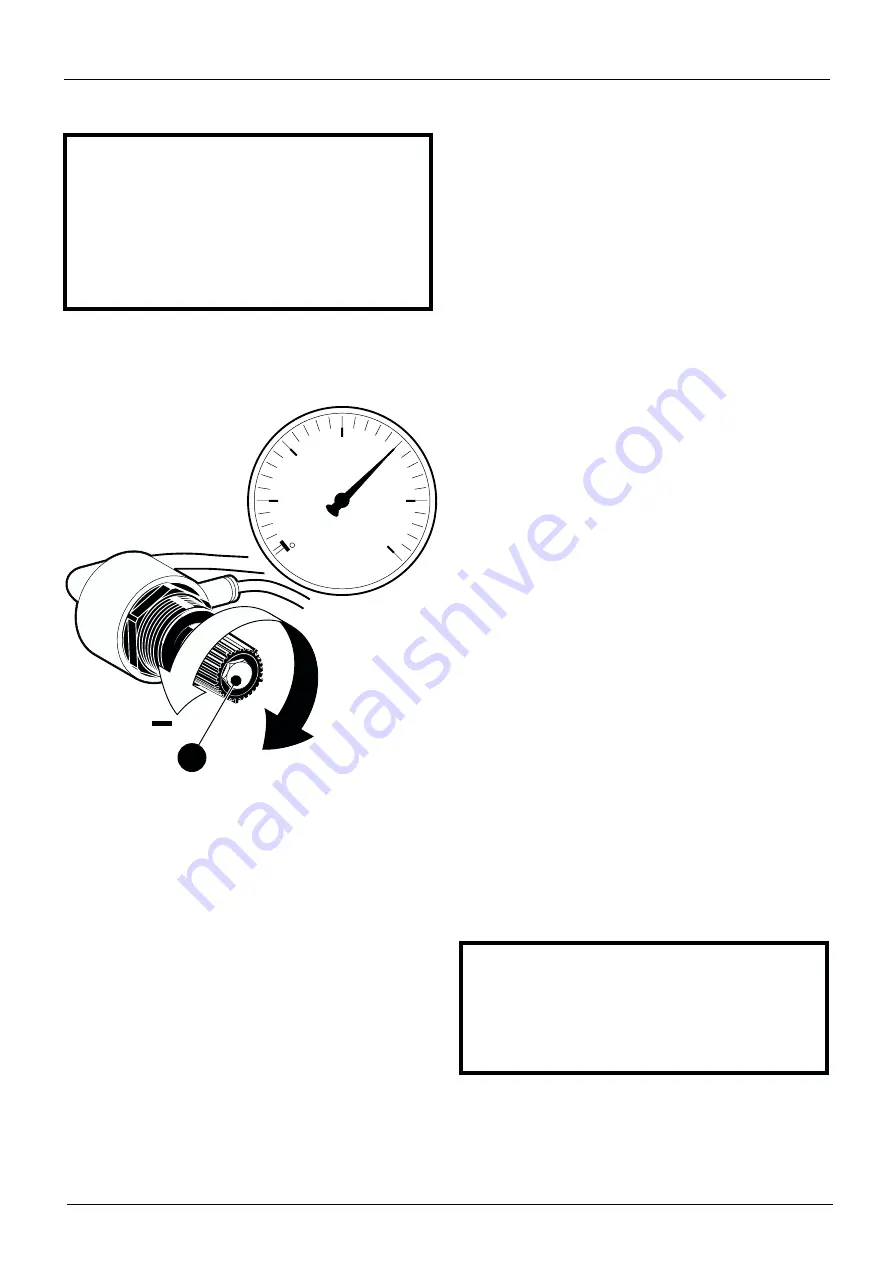

• At the pressure regulator, pull the control

knob out until the snap lock on the knob is

released and the control knob can be

turned freely.

Note

– If the regulator is

equipped with a screw (1), first release the

screw a couple of turns.

• Turn the control knob until the manometer

indicates an output pressure of 400 kPa

±50 kPa (4.0 bar ±0.5 bar):

– To increase the pressure, turn the knob

in a clockwise direction.

– To decrease the pressure, turn the knob

in a counter-clockwise direction.

• Push in the control knob until the snap lock

on the knob is engaged and the control

knob cannot be turned.

Note

– If the regulator is equipped with a

screw (1), tighten the screw.

• Switch off the compressor with the on/off

switch and remove the test nozzle.

• Close and secure the compressor’s front

cover.

After any service intervention in the

Compressor Compact, perform a

Functional check according to

instructions in the Operating Manual.

COMP036X

0

1

2

3

4

5

6

bar

+

1

This adjustment is performed with mains

power connected and energized electrical

components as well as moving mecha-

nical parts in the Compressor Compact.

All personnel must exercise extreme

caution when in the vicinity of the unit.