Removal from Switchgear

Prior to performing any inspection or maintenance checks

or tests, the circuit breaker must be removed from the

switchgear. The Installation and Initial Functional Tests

section describes the removal procedure in detail. Princi-

pal steps are repeated here for information and guidance,

but without the details of the preceding section.

Note: The Racking Mechanism is adjusted for proper

operation and should not be disturbed unless it be-

comes possible to close the breaker during a racking

operation.

It may be possible that interlocked blocking members

are not positioned properly, which should be corrected

as follows:

Remove the lower front mechanism cover plate and

with the circuit breaker closed, make adjustment by

regulating the length of connecting rod (Figure 2).

1. The first step is to de-energize the circuit breaker. De-

pressing the Trip pushbutton opens the breaker prior to

removal from the switchgear (Refer to Circuit Breaker

Operator / Manual SG-9918).

2. The second step in the removal procedure is to de-en-

ergize control power to the circuit breaker. Open the

control power disconnect device.

3. Rack the breaker to the “DISCONNECT” position.

4. Perform the spring discharge check. This is done by

first depressing the red Trip pushbutton. Second, de-

press the back Close pushbutton. Third, depress the

red Trip pushbutton again, and observe the spring con-

dition indicator. It should read Discharge (Refer to Cir-

cuit Breaker Operator / Manual SGIM-9918).

5. Remove the breaker from the switchgear. Refer to the

preceding installation section of this manual for special

instructions and precautions regarding removal of a

breaker which is not at floor level.

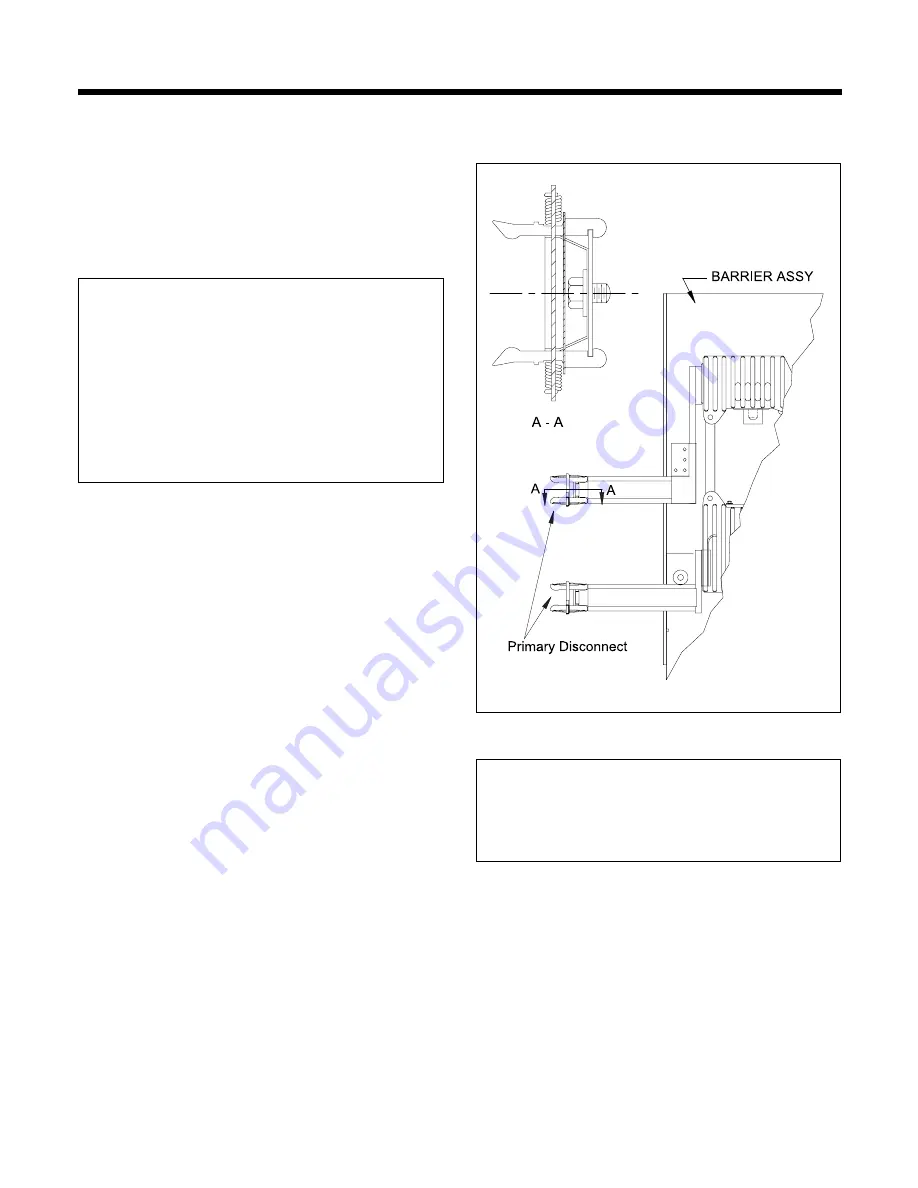

Checks of the Primary Power Path

The primary power path consists of the three vacuum

interrupters, the three upper and the three lower primary

disconnects. These components are checked for

cleanliness and condition (Figure 4). The vacuum

interrupters are discussed in the Circuit breaker Operator

Manual SGIM-9918.

Maintenance

Figure 4. Primary Power Path

Inspection of Primary Disconnects and Cleanliness Check

Figure 4 is a side view of the DPR Circuit Breaker with the

insulating barriers removed to show the vacuum inter-

rupter, and the upper and lower primary disconnects.

All of these components must be clean and free of dirt or

any foreign objects. Use a dry lint-free cloth. For stubborn

dirt, use a clean cloth saturated with denatured alcohol.

The phase barriers are plates of glass polyester insulating

material and attached to the circuit breaker to provide suit-

able electrical insulation between the vacuum interrupter

primary circuits and the housing.

8

Note: Maximum Contact Resistance is read from pri-

mary bus stab to primary bus stab. A value of 13

micro-ohms should be added to the maximum con-

tact resistance specified in Circuit Breaker Operator

Manual SGIM-9918.