Vehicle Description

5

the test position. The rollers on the arms strike vertical

angles on the cell wall and stop the breaker at the test

position. If the breaker is to be operated at this position,

remove the crank and engage the secondary contacts in

the manner described in the section under Secondary Con-

tacts. To move the breaker from the test position to the

fully engaged operating position, put the crank on the shaft,

push in and rotate to engage the levering-in coupling, and

crank clockwise. The torque required will increase when

the primary contact fingers engage the stationary contact

studs in the cell. Continue cranking to the end of the travel

where the interlock will again fall free, pushing the crank

back out. Remove the crank. The indicator on the panel

will again point to the word “OPERATE”.

To remove the breaker from the operating position, first

check that the breaker is open. The levering-in device can-

not be engaged unless the breaker contacts are open. Put

the crank on the operating shaft, push in and rotate to en-

gage the coupling, and turn counterclockwise until the

breaker returns to the test position. Remove the crank.

The breaker may now be operated at the test position or

rolled out of the cell.

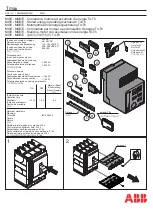

Figure 2. Interlock Position Indicator

Interlock Position Indicator

The interlock position indicator (Figure 2) gives a positive

indication of the position of the breaker interlock. It oper-

ates from the levering-in device shaft. When the indica-

tor points to the word OPERATE, the interlock is free and

the breaker may be closed or tripped. When the indicator

points to the word INTERLOCKED, the interlock is func-

tioning and the breaker cannot be closed. Since the inter-

lock is operative only when the breaker is in fan interme-

diate position between fully engaged and fully withdrawn,

it also serves as a means of indicating that the breaker is

in the Operating Position and the main disconnecting con-

tacts fully engaged, or that it is in the Test Position with

the contacts separated.

Test Position

The breaker may be rolled into the metal clad cell until the

rollers on the levering-in device stop against a pair of ver-

tical angles welded into the cell. The levering-in device is

not operated. This is the test position in which the breaker

primary contacts are separated from the energized con-

tacts in the cell, and a metal shutter is closed completely

isolating all high voltage parts from the breaker. The sec-

ondary contacts may be engaged and the breaker oper-

ated safely for test purposes without the arc chutes or bar-

rier.

Operating Position

The breaker may be moved from the test to the operating

position by engaging the levering-in device and rotating

the levering-in crank clockwise. As the breaker travels

beyond the Test Position, the metal shutter covering the

high voltage primary contacts will be automatically opened

by the shutter rollers which are locate on each side of the

breaker frame at the rear (Figure 1a). At the end of the

travel, all the breaker contacts are engaged. This is the

Operating Position.

Interlock

The interlock on the DH breakers has two functions to per-

form. First, it prevents the breaker from being moved from

the test to the operate position or vice versa with the con-

tacts closed. Second, if the breaker is in some intermedi-

ate position between the test and operate positions, it pre-

vents the contacts from being closed.

This interlocking action is accomplished by having a rod,

operated by the breaker mechanism, and a pin operated

by the levering-in device, move at right angles to each

other.