Document No: IOM-002

Issue Date:

24/09/2020

Revision:

6

Page:

7 of 42

Unrestricted

2.2

Product specification and certification

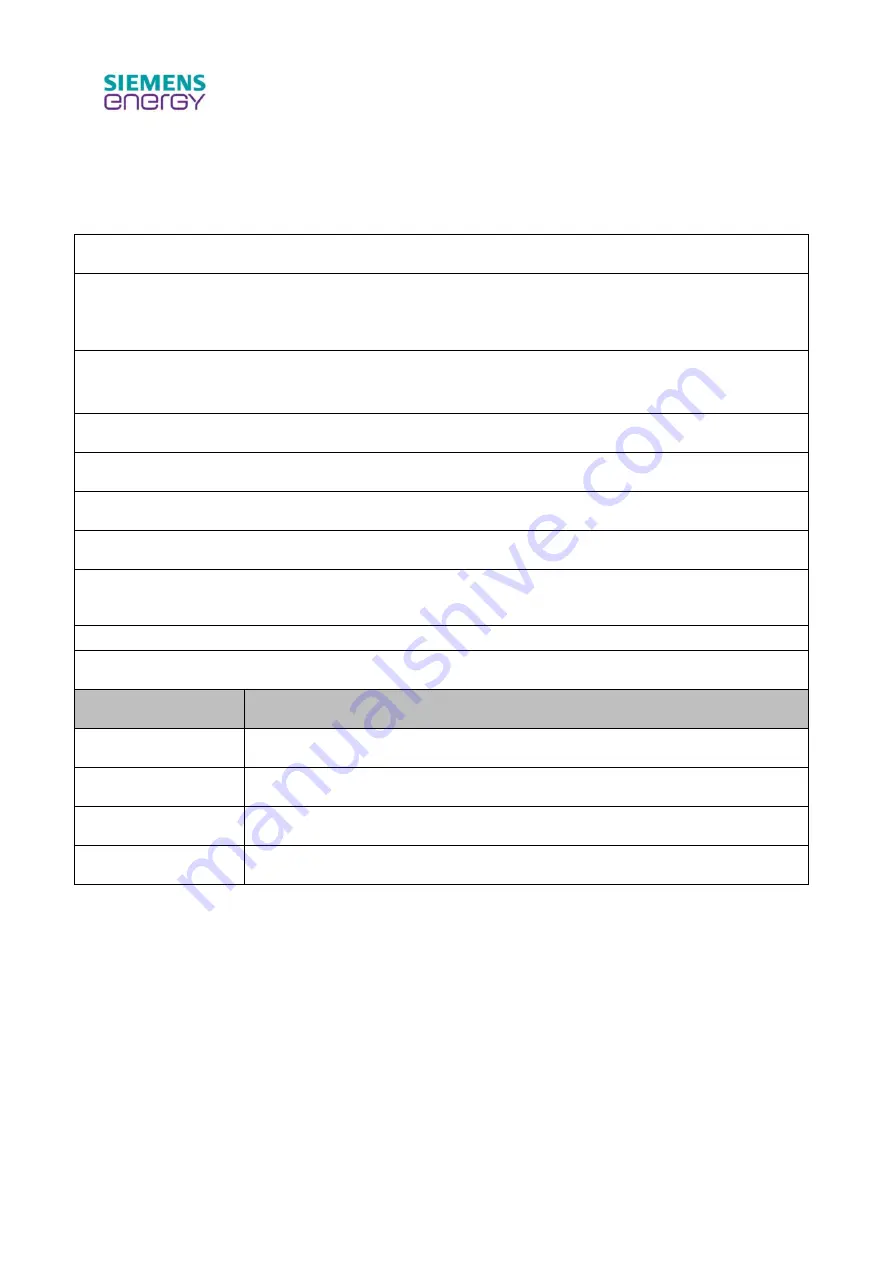

Basic specifications relating to all products covered by this manual are below in Table 3. Additional

specifications can be found in section 5.

Design Life:

30 years in subsea environment

Rated voltage

DigiTRON

+

1,000Vac pin-ground, 2,000Vac pin-pin

DigiTRON

e

Ethernet lines 50Vdc, other lines as DigiTRON

+

DigiTRON3 1,800Vac pin-ground, 2,000Vac pin-pin

Rated current

In water: 4-way 35-40A 7-way 22-32A 12-way 20-28A

In air: 4-way 18A 7-way 14A 12-way 11A

(Excludes ethernet lines)

Over-current

100A for 5 seconds, no more than 2 per hour

Rated number of

operations

1000 (750dry/250wet) mate / de-mate cycles (Power off)

Water depth

4,000 m (13,123ft)

Storage temperature

-40°C +70°C (-40°F +158°F) (upper limit is surface temperature of the

product and includes solar gain from bright sunlight)

Operational temp

Subsea: -5°C +60°C (+23°F +140°F)

In air: -20°C +50°C (-4°F +122°F)

Product Certification:

Standard

Description

EU Directive

2001/95/EC

General Product Safety

EU Directive

2014/35/EU

Low Voltage Directive

IEC 61984

Connectors - Safety requirements and tests

API-17F

Standard for Subsea Production Control Systems

Note: Self-certified via in-house testing.

Table 3

DigiTRON product specification and certification