Contents

ECOFAST Motor Starters

GWA 4NEB 950 5221-12 DS 01

i

Deutsc

h

En

glish

Contents

Motor Starters: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What are ECOFAST Motor Starters? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections, fieldbus interfaces, LED indicators . . . . . . . . . . . . . . . . . . . . . . . . .

Fieldbus interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unused Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Cables and Motor Connection Cables Prefabricated at One End. . . . . . . . . . . .

Power Cables Prefabricated at One End with Han Q4/2 Pin . . . . . . . . . . . . . . . . . .

Power Cables Prefabricated at One End with Han 10E Pin . . . . . . . . . . . . . . . .

Prefabricating Motor Connection Cables . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Power tee clamping connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Behavior in the event of a power failure . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

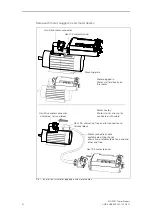

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process data and process images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics with the addressing and diagnostic unit . . . . . . . . . . . . . . . . . . . . . . .

Summary of Contents for Ecofast 3RK1 323-2AS54-1AA0

Page 1: ...Motor Starter Manual 03 2007 ecofast Totally Integrated Automation ...

Page 2: ......

Page 12: ...ECOFAST Motor Starters viii GWA 4NEB 950 5221 12 DS 01 ...

Page 40: ...Installation of Motor Starters ECOFAST Motor Starters 3 8 GWA 4NEB 950 5221 12 DS 01 ...

Page 58: ...Device functions ECOFAST Motor Starters 6 6 GWA 4NEB 950 5221 12 DS 01 ...

Page 74: ...ECOFAST Motor Starters GWA 4NEB 950 5221 12 DS 01 ...

Page 75: ......