10

FLUDEX 4600 en

Operating instructions 10/2017

4.

Transport and storage

Observe the instructions in section 3, "Safety instructions"!

4.1

Scope of supply

The products supplied are listed in the dispatch papers. Check on receipt to ensure that all the products

listed have actually been delivered. Parts damaged during transport or missing parts must be reported in

writing immediately.

The equipment is delivered ready for operation, depending upon an order with or without fluid filling.

Couplings filled with operating medium are marked by a label ("...L, HLP 32 DIN 51524/2, operating oil

already put in") in the vicinity of the filling hole. Delivered separately with every coupling is a fusible safety

plug (depending on design also a thermal circuit breaker) with sealing rings, a locking plate and a retaining

screw, if provided for.

The coupling in design in accordance with the Directive 2014/34/EU is provided with the

CE identification mark as described in section 5.

4.2

Transport

When transporting the unit, use only lifting and handling equipment of sufficient

loadbearing capacity.

The coupling must be transported using suitable transport equipment only.

Different forms of packaging may be used depending on the size of the coupling and method of transport.

Unless otherwise agreed, the packaging complies with the

HPE Packaging Guidelines.

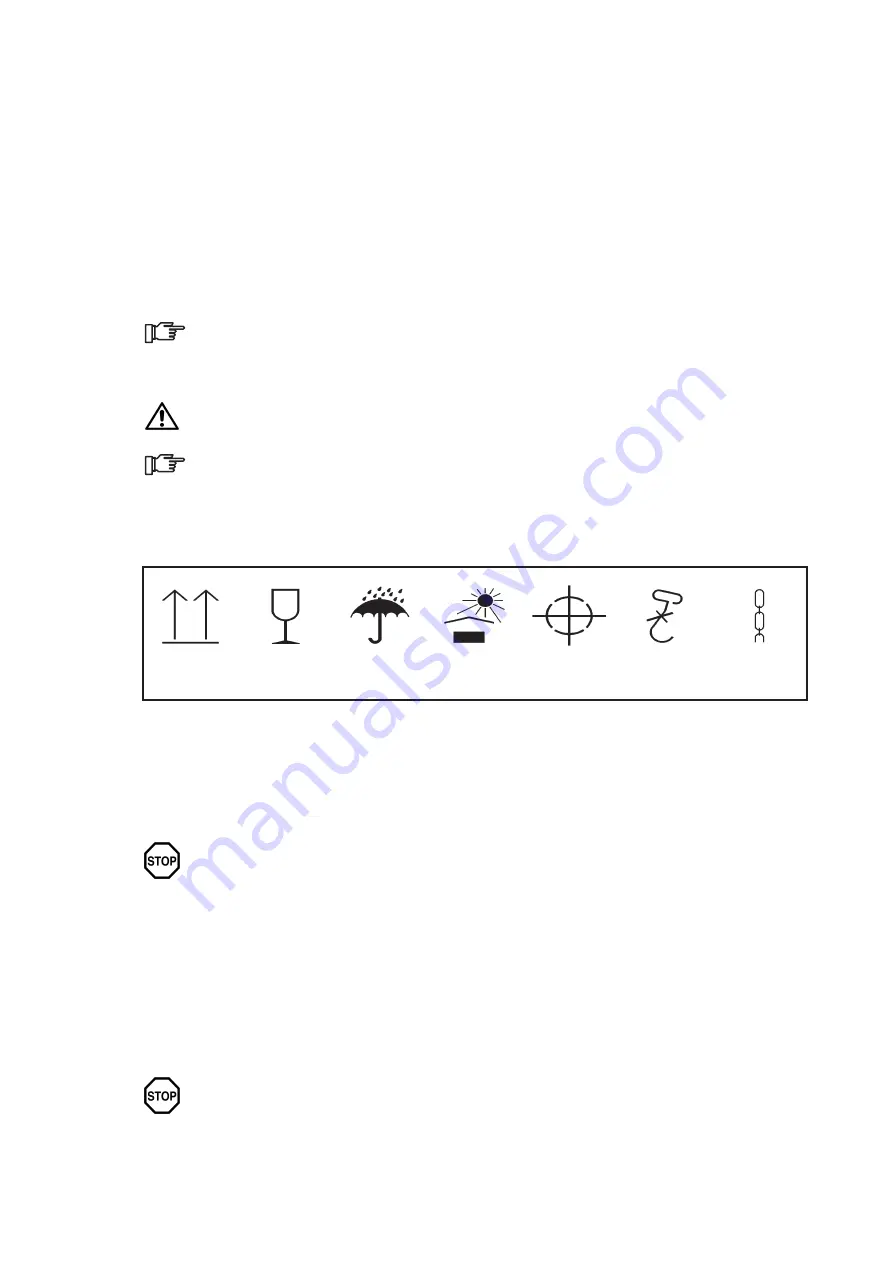

The symbols marked on the packing must be observed at all times. These have the following meanings:

Top

Fragile

Keep dry

Keep cool

Centre of

gravity

Use no hand

hook

Attach

here

Fig. 2:

Transport symbols

4.3

Storage of the coupling

Unless otherwise expressly agreed, the coupling is delivered in a preserved condition and can be stored

in a covered, dry place for up to 3 months. If storage is provided for a protracted period, the unit should be

treated with a longterm preservative agent on all outer surfaces with the exception of the aluminium

housing (Flender must be consulted).

+

Before cleaning the coupling and applying the longterm preservative agent, any

flexible elements of the NEUPEX addon coupling must be removed. The shaft-sealing

rings must not come into contact with solvents.

Correctly stored couplings retain their properties unchanged for up to five years. Unfavourable storage

conditions and improper treatment of the flexible elements and/or seals will negatively affect their physical

properties. Such negative effects may be caused by e.g. the action of oxygen, ozone, extreme

temperatures, light, moisture, or solvents.

4.4

Storage area for a protracted period

The storage area must be dry and free from dust. The couplings must not be stored with chemicals,

solvents, motor fuels, acids, etc. Furthermore, the flexible elements and seals should be protected against

light, in particular direct sunlight and bright artificial light with a high ultraviolet content.

The storage areas must not contain any ozonegenerating equipment, such as

fluorescent light sources, mercury vapour lamps, highvoltage electrical equipment.

Damp storage areas are unsuitable. Ensure that no condensation occurs. The most

favourable atmospheric humidity is below 65 %.

Summary of Contents for Flender FLUDEX 4600 FAD Series

Page 2: ......