29

FLUDEX 4600 en

Operating instructions 10/2017

10.5

Disassembling the FLUDEX coupling

For part designations, see section 11.

Risk of burns after switching off.

Allow the FLUDEX coupling to cool down sufficiently before beginning work.

10.5.1

Disassembling the sizes 222 to 342

After moving the motor away the retaining screw (141) and locking plate (140) are first removed and then

the locking ring (124) demounted. When pulling off the FLUDEX coupling, care must be taken that

pullingoff forces are conducted only through the steel hollow shaft (106).

The coupling is best pulled off with the aid of a special detaching device as shown in figure 12. The spindle

with the pullingoff nut is inserted so that the collar (D) of the pullingoff nut is located behind the recess

for the locking ring (124) (Fig. 13). To prevent the spindle seizing, the pressure surface and the thread must

be treated with a lubricant (e.g. Molykote).

Spindle

L

Nut

D

G

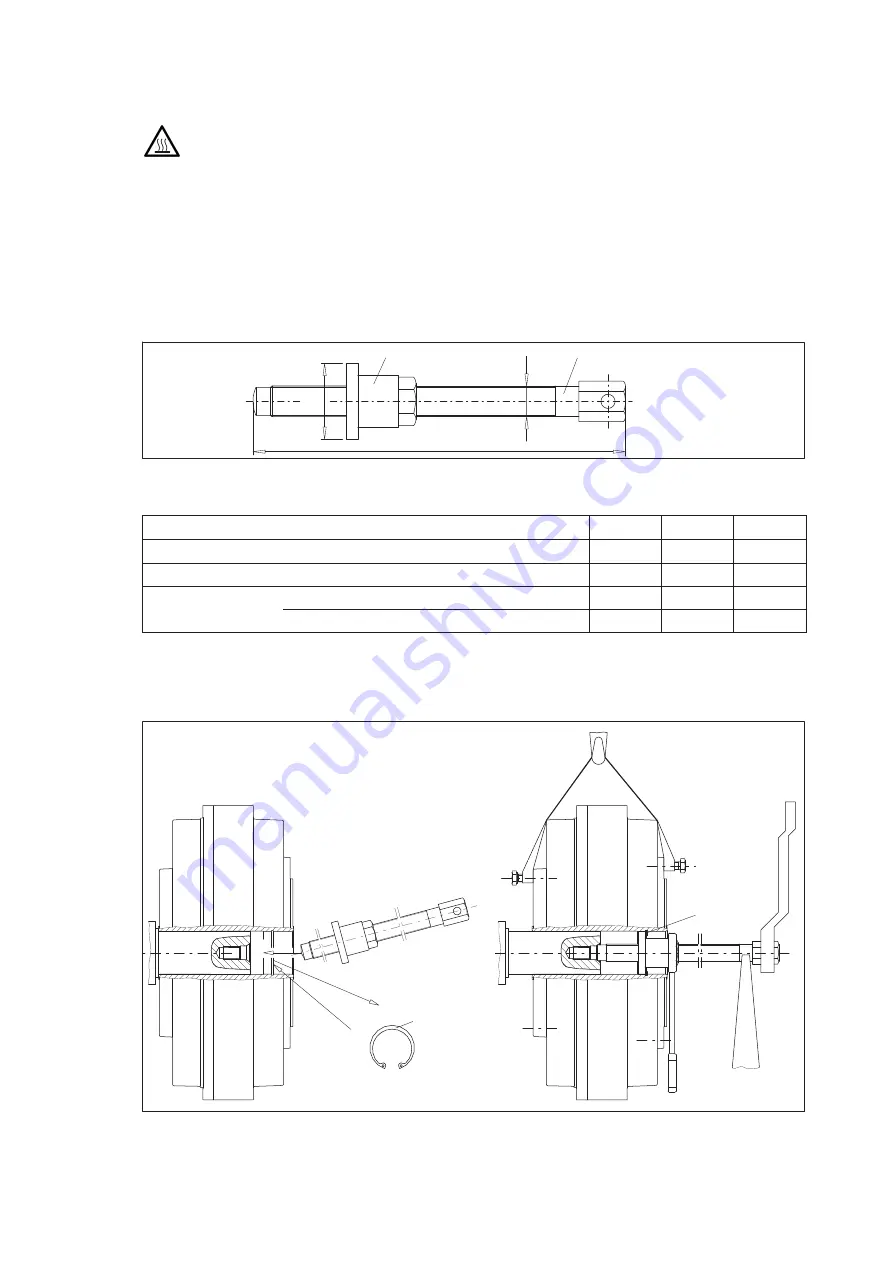

Fig. 12:

Disassembling the sizes 222 to 342 -a

Table 11:

Dimensions of the threaded spindle and pullingoff nut, sizes 222 to 342

Size

222

297

342

Spindle thread G

G 1/4

G 1/2

G 3/4

Nut collar D

h8

[mm]

30

45

55

Spindle length L

[mm]

FAO, FAK, FAKB, FAD, FADB, FAE, FAM, FADS

200

305

280

FAR

200

305

420

The locking ring (124) is refitted and the spindle turned forward as far as the shaft stub end face and into

the safety countersink in the centring thread. Care must be taken that the nut collar rests evenly against

the locking ring.

To prevent flexing and canting, the spindle should be supported as shown.

1

3

2

124

124

Fig. 13:

Disassembling the sizes 222 to 342 -b

The coupling is pulled off the shaft stub by turning the spindle further into the forcingoff thread and bracing

the nut. It is recommended that a hydraulic spindle be used, depending on the size of the coupling.

Summary of Contents for Flender FLUDEX 4600 FAD Series

Page 2: ......