22

FLUDEX 4612 en

Operating instructions 10/2017

For drive by means of parallel keys the following fit pairs are prescribed for the bores:

Table 2:

Fit pairs

Selection of fit

Bore D

1

Shaft tolerances

Bore tolerances

over

mm

up to

mm

Shaft tolerance

to FLENDER standard

25

k6

H7

25

100

m6

100

n6

Shaft tolerance

to DIN 748/1

50

k6

H7

50

m6

System "standard shaft"

50

h6

K7

50

M7

all

h8

N7

NOTICE

Damage to the coupling, damage to other components

Risk of damage to the coupling through incorrect rework (e.g. incorrect fit assignment).

The assigned fits must be adhered to in each case.

Depending on the utilisation of the tolerance zones, the following items must be observed:

– Keep the play in the shafthub connection as low as possible.

– Keep the hub tension arising from the oversize within the permissible load limit.

Failure to adhere to the fit assignments may impair the shafthub connection.

If the tolerance values of the shafts deviate from those in table 2, Flender must be consulted.

6.1.2

Parallel keyway

The parallel keyways must be designed in accordance with standard "DIN 6885/1". If the keyway geometry

deviates, Flender must be consulted. Taper keys or nose keys (gib headed keys) are not permissible.

The parallel keyways must be designed to suit the available parallel keys. For parallel keyways the

tolerance zone of the hub keyway width

"ISO JS9"

must be adhered to.

Note

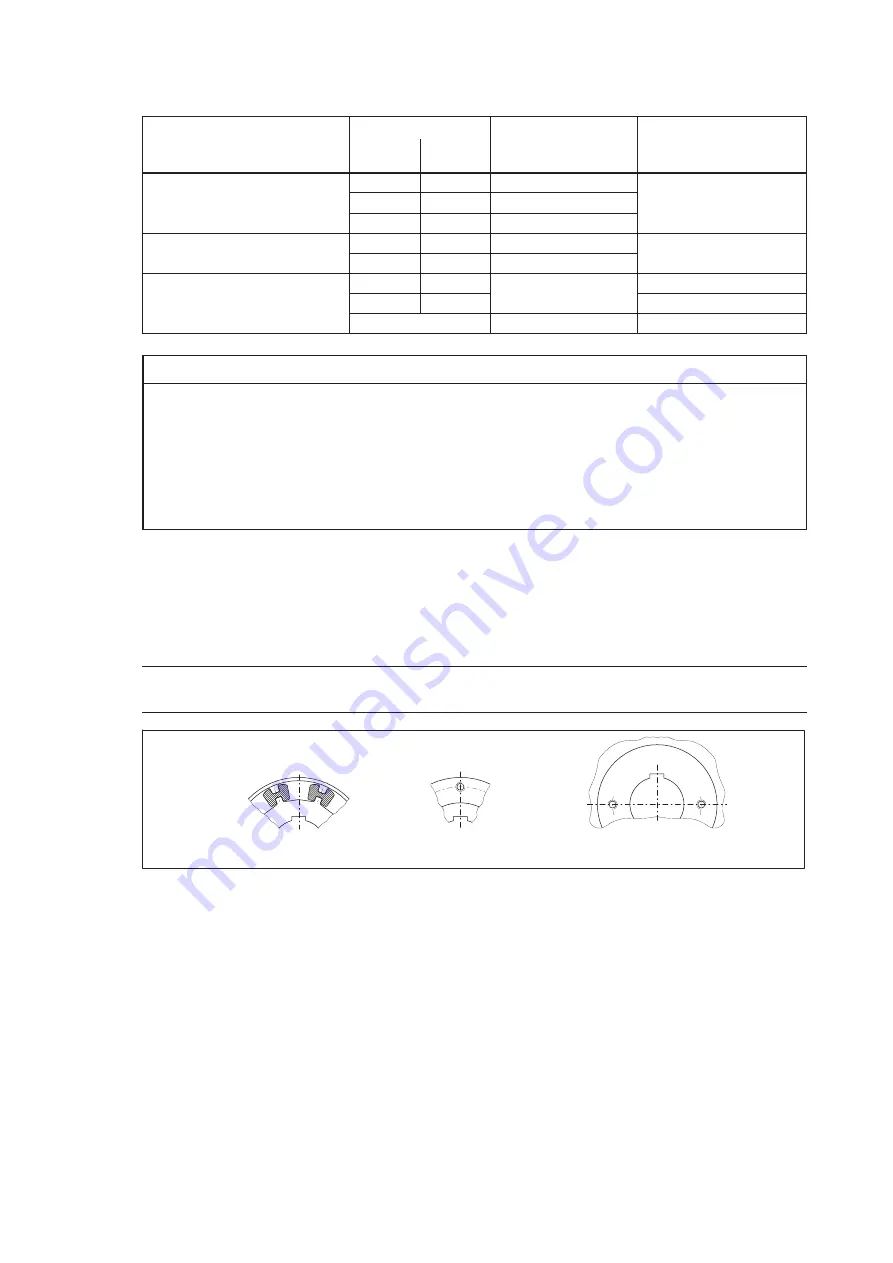

The parallel keyway must be machined as shown in the illustration.

Part 1

Part 120

Part 11 / 32

Fig. 5:

Parallel keyway

Summary of Contents for FLENDER FLUDEX FNA

Page 2: ......