Fusesaver

| Installation and operation manual

19

6 Maintenance

Battery specification

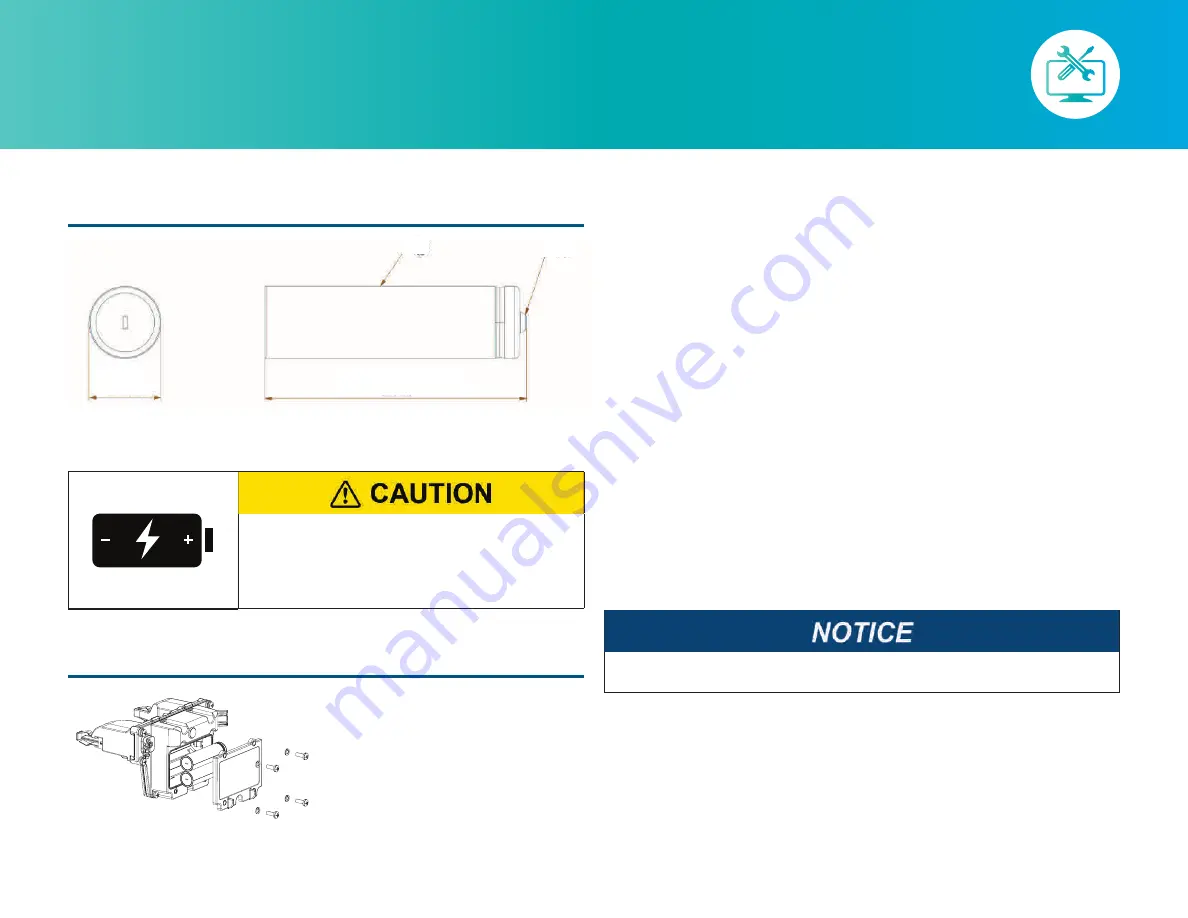

1) Molicel lithium-ion battery

(18650, 3.6 V, 2000 mAh).

2) Contact nipple to be welded to

positive terminal by specialist

battery manufacturer.

Replace the battery cells according to the following procedure:

Battery replacement

A. Remove the battery compartment

cover by undoing the four screws.

B. Remove the battery cells from

their holder.

C. Fit new cells while ensuring

correct polarity.

D. Press both actuators and conduct

a battery test according to section

3.3 and confirm batteries are

adequately charged.

E. Check and clean battery cover

compartment seal.

F. Fit battery compartment cover

by tightening screws.

G. Reset the battery life by holding

down the GREEN lever for 10

seconds. LED blinks 3 times quickly

to confirm battery life is reset.

H. If required, connect a charger

to recharge batteries.

I. Communications module is ready

for return to service.

6.3 Battery charging

The battery cells in the rechargeable

communications module can be

recharged using a standard off-the

-shelf battery charger suitable for

18650 lithium-ion cells.

A. Remove the battery cells from

the rechargeable communications

module.

B. Charge the battery cells using the

bench charger and according to the

instructions of the charger unit.

C. Fit the battery cells back into the

communications module taking

care to get the polarity correct.

D. Fit the cover and tighten the screws

ensuring the seal is correctly

seated.

Recharging of the batteries in the primary cell communications module

is not possible.

•

Siemens does not approve the use of

alternative battery types.

•

This battery MUST NOT be used without the

nipple fitted.

2

1

Ø 0.71”

(18 mm)

2.64” (67 mm)