7/44

Siemens

Technische Grundlagen: Drehantriebe GEB...1

CM2Z4621en

Building Technologies

2017-05-26

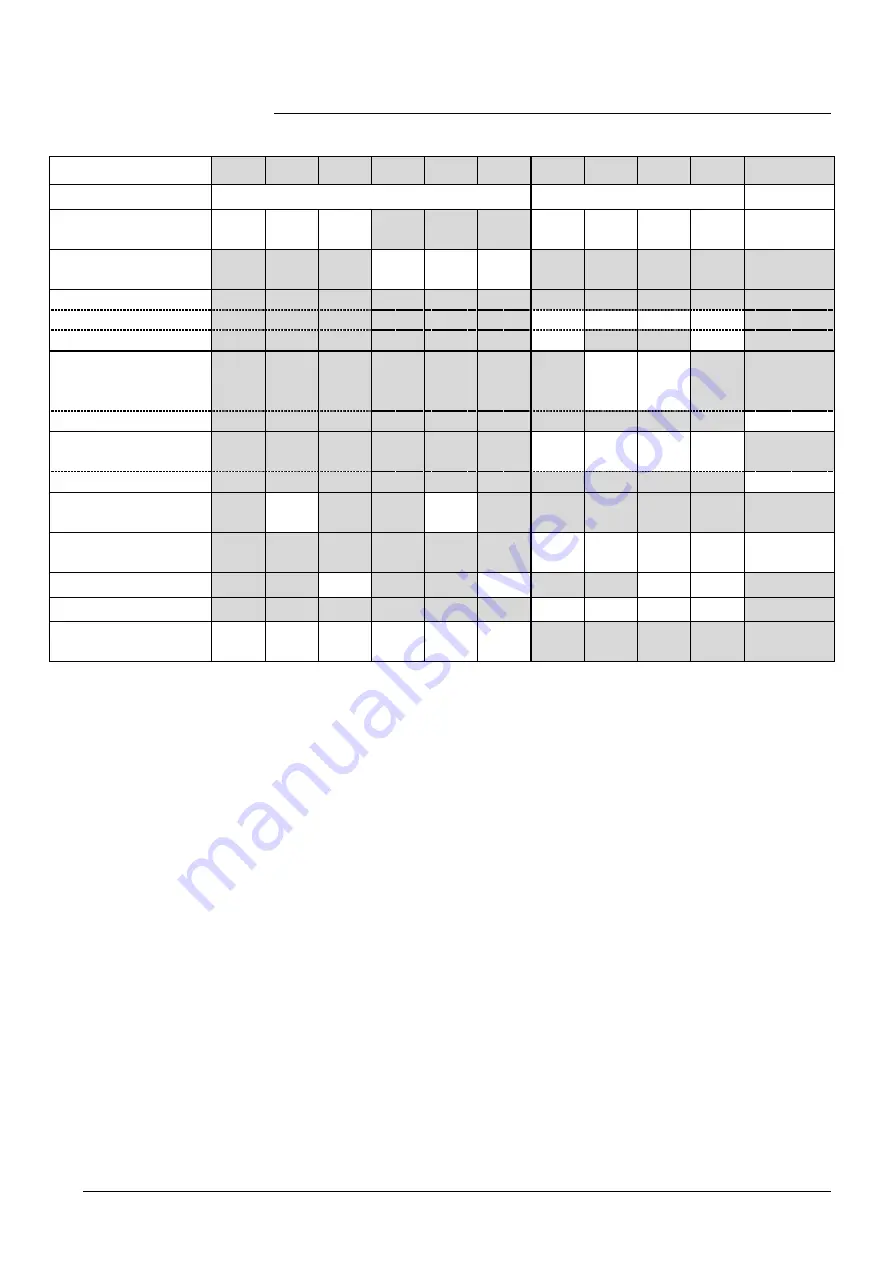

2.2 Type

summary

The following table shows the options for the actuator types.

GEB....

131.1E

132.1E

136.1E

331.1E

332.1E

336.1E

161.1E

163.1E

164.1E

166.1E

161.1E/MO

Three-position control

Modulating control

Modbus RTU

Operating voltage

AC 24 V

X

X

X

X

X

X

X

X

Operating voltage

AC 230 V

X

X

X

Positioning signal input Y

DC 0...10 V

X

X

X

X

DC 2...10 V

X

X

DC 0...35 V

with characteristic

function

X

X

Modbus RTU

X

Position indicator

U = DC 0...10 V

X

X

X

X

Modbus RTU

X

Feedback potentiometer

1k

ς

X

X

Self-adaptation of rotary

angle range

X

X

X

X

X

Auxiliary switches (two)

X

X

X

X

Rotary direction switch

X

X

X

X

Powerpack (two actuators,

tandem-mounted)

X

X

X

X

X

X

For functional enhancements of the actuators, the following accessories are available:

External auxiliary switches (1 switch)

ASC77.1

External auxiliary switches (2 switches)

ASC77.2

Universal lever

ASK71.9

Rotary/linear set for duct and wall mounting

ASK71.11

Rotary/linear set with lever

ASK71.13

Rotary/linear set with lever and mounting plate

ASK71.14

Weather protection cover

ASK75.3

Mounting bracket for tandem-mounted actuators or Powerpack

ASK73.3

Data sheet for accessories and spare parts

N4697

Accessories, spare parts

Accessories