Diagnosing and troubleshooting

10.3 Common problems chart

HydroRanger 200 HMI

Operating Instructions, 06/2018, A5E36281317-AC

285

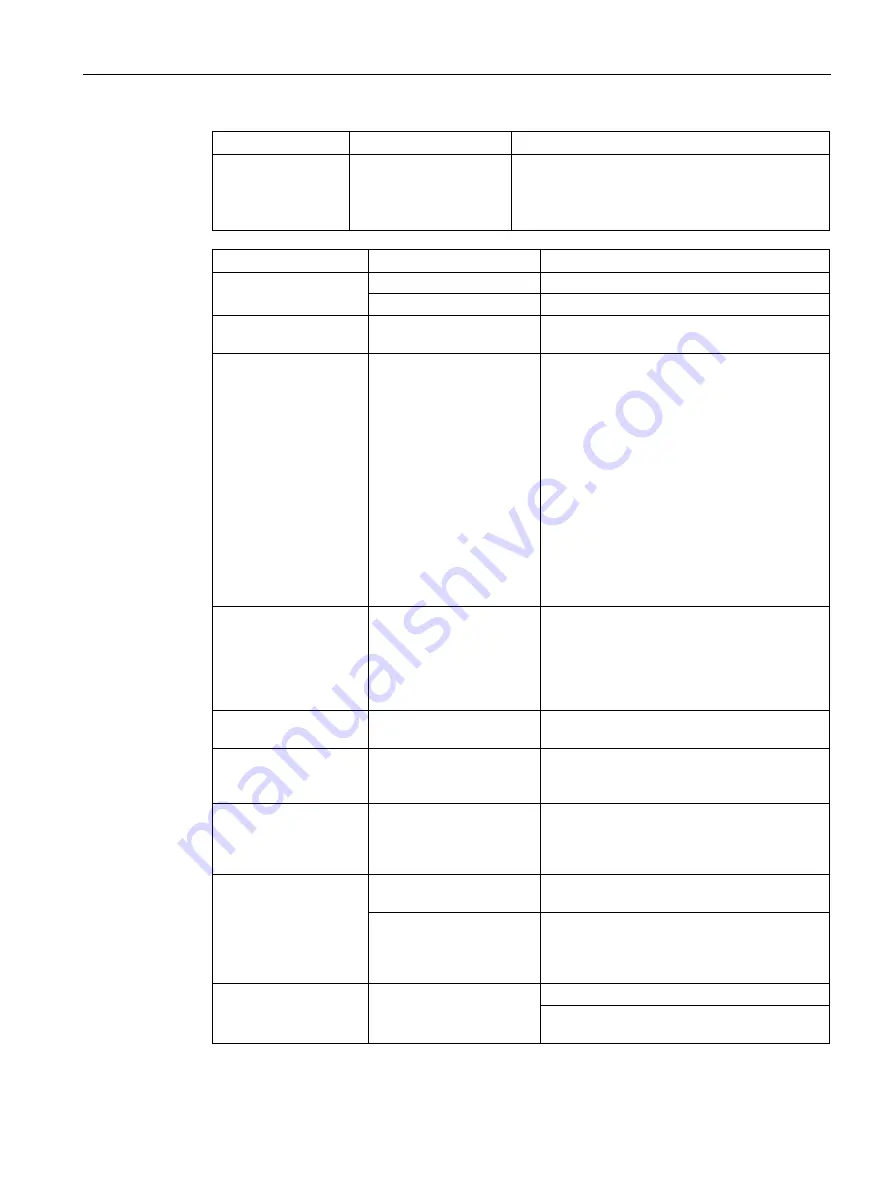

Symptom

Possible cause

Action

Incorrect vessel or PMD

dimensions

For volume application: Verify vessel dimensions.

See Vessel shape (2.7.2.) (Page 186).

For flow application: Verify PMD dimensions. See

PMD dimensions (2.13.5.) (Page 246).

Symptom

cause

Action

Relay not activating

Relay not programmed

Program relay.

Incorrect relay setpoints

Verify setpoints.

Relay not activating

correctly

Incorrect relay setpoints

Verify setpoints.

Configuration error 130

displayed

Relay/pump configuration

errors - possible causes

include:

•

A relay is assigned to

more than one function

(e.g. Relay 2 is as-

signed to both an ex-

ternal totalizer and a

pump).

•

Pump setpoints are out

of order.

•

Wall cling adjustment

range is too large.

•

Verify that each relay is assigned to one

function only. Review relay assignments

under Relay selector (2.8.1.1.) (Page 193)

and Other Control (2.10.) (Page 210).

•

Verify that all 'ON' setpoints are greater

than their respective 'OFF' setpoints for

pump down applications (or vice versa for

pump up applications).

•

Ensure range set in Level setpoint varia-

tion (2.8.2.6.2.) (Page 204) has not caused

'ON' or 'OFF' setpoints to overlap.

Echo profile request

results in an error icon

that displays for 5 sec-

onds before returning to

the echo profile request

menu.

Another external commu-

nication is trying to access

an echo profile at the

same time.

Wait for several seconds and then retry the

echo profile request, or disconnect / disable

any external communications that may be

requesting an echo profile.

Display blank, trans-

ducer not pulsing.

No power.

Check power supply, wiring, or power fuse.

No response to pro-

grammer.

Obstructed infrared inter-

face, defective program-

mer.

Check programmer usage: 15 cm (6 inch)

from faceplate pointed at upper target.

Displays Short and

tb:(#).

Short circuited transducer

cable, or defective trans-

ducer at indicated terminal

block number.

Repair or replace as necessary.

Displays Open and

tb:(#).

Transducer not connected

or connection reversed.

Check connection to displayed terminal

blocks.

Open circuited transducer

cable, or defective trans-

ducer at indicated terminal

block number.

Repair or replace as necessary.

Displays LOE.

Weak or non-existent

echo.

Relocate and/or re-aim transducer at material.

Proceed toMeasurement difficulties

(Page 289).

Summary of Contents for HydroRanger 200 HMI

Page 2: ......

Page 24: ...Safety notes HydroRanger 200 HMI 22 Operating Instructions 06 2018 A5E36281317 AC ...

Page 354: ...Updating software HydroRanger 200 HMI 352 Operating Instructions 06 2018 A5E36281317 AC ...

Page 362: ......

Page 403: ......