Diagnosing and troubleshooting

10.4 Noise problems

HydroRanger 200 HMI

286

Operating Instructions, 06/2018, A5E36281317-AC

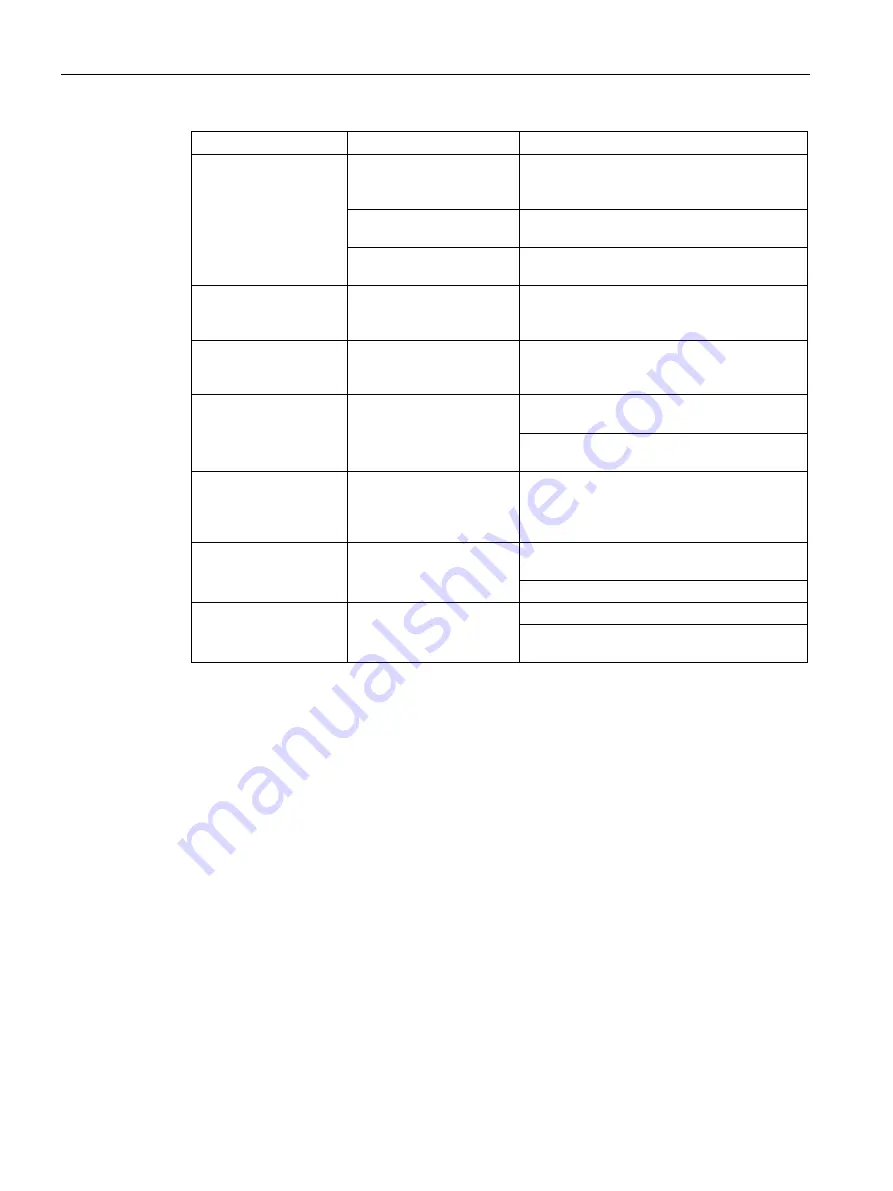

Symptom

cause

Action

Displays Error and

tb:(#).

Wrong transducer selected

Verify transducer type and re-enter value.

Transducer connected in

“two-wire” method.

Do not tie white and shield together. Use all

three terminal blocks.

Transducer connected

backwards.

Reverse black and white wires on terminal

block.

Displays EEEE

Value too large to display

in 4 or 5 characters.

Select larger units [ Units (2.1.1.) (Page 162)],

or lower convert reading [Convert reading

Reading fluctuates

while material level is

still (or vice versa).

Incorrect measurement

stabilization.

Alter rate of response [Response rate (2.3.4.)

(Page 174)] or rate filter [Rate filter (2.3.5.)

(Page 175)] accordingly.

Reading is fixed, re-

gardless of the actual

material level.

Transducer acoustic beam

obstructed, standpipe too

narrow, or transducer

ringing (reads over 100%).

Relocate and / or re-aim transducer at materi-

al level or object.

Proceed to Measurement difficulties

(Page 289).

Material level reported

is always incorrect by

the same amount.

Incorrect empty (zero)

reference for level opera-

(Page 163) = *Level].

See Empty (2.2.4.) (Page 170), Offset reading

(2.12.6.) (Page 238), Sensor offset (2.2.5.)

(Page 171), Offset correction (2.11.1.9.)

(Page 221)

Measurement accuracy

improves as level nears

transducer.

Incorrect Sound Velocity

used for distance calcula-

tion.

Use a transducer with a built-in temperature

sensor or a TS-3 temperature sensor.

See Sound velocity (2.11.1.2.) (Page 218).

Reading is erratic, with

little or no relation to

material level.

True echo too weak or

wrong echo being pro-

cessed.

Relocate and/or re-aim transducer at material.

Check noise parameters. See Noise problems

(Page 286).

10.4

Noise problems

Incorrect readings can be the result of noise problems, either acoustic or electrical, in the

application. The noise present at the input to the ultrasonic receiver can be determined by

viewing the echo profile locally via the HMI, or alternatively, using remote software such

SIMATIC PDM. View also parameters Noise Average (3.2.11.5.) (Page 263) and Noise Peak

(3.2.11.6.) (Page 263). In general, the most useful value is the average noise.

With no transducer attached the noise is under 5 dB. This is often called the noise floor. If

the value with a transducer attached is greater than 5 dB, signal processing problems can

occur. High noise decreases the maximum distance that can be measured. The exact

relationship between noise and maximum distance is dependent on the transducer type and

the material being measured. An average noise level greater than 30 dB may be cause for

concern if the installed transducers maximum operation range matches the range of the

application (e.g. 8 m application using an 8 m XRS-5). Using a larger transducer with greater

transmitted energy should help to improve performance in a noise condition.

Summary of Contents for HydroRanger 200 HMI

Page 2: ......

Page 24: ...Safety notes HydroRanger 200 HMI 22 Operating Instructions 06 2018 A5E36281317 AC ...

Page 354: ...Updating software HydroRanger 200 HMI 352 Operating Instructions 06 2018 A5E36281317 AC ...

Page 362: ......

Page 403: ......