Summary of Contents for I-T-E Sensitrip MD Series

Page 2: ......

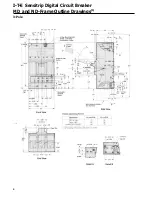

Page 6: ...4 I T E Sensitrip Digital Circuit Breaker MD and ND Frame Outline Drawings 1 3 Pole ...

Page 8: ...6 MD and ND Frame Trip Adjustments ...

Page 12: ...10 MD and ND Frame Time Current Curve 600 1000A With Short Time Delay Set on Fixed Time ...

Page 13: ...MD and ND Frame Time Current Curve 11 1200A With Short Time Delay Set on Fixed Time ...

Page 14: ...12 MD and ND Frame Time Current Curve 600 100A With Short Time Delay Set on I2 t ...

Page 15: ...MD and ND Frame Time Current Curve 13 1200A With Short Time Delay Set on I2 t ...

Page 16: ...14 MD and ND Frame Time Current Curve 600 100A Without Short Time Settings ...

Page 17: ...MD and ND Frame Time Current Curve 15 1200A Without Short Time Settings ...

Page 18: ...16 MD and ND Frame Time Current Curve Ground Fault Trip Data ...

Page 19: ...MD and ND Frame Time Current Curve 17 Example ...

Page 20: ...18 MD and ND Frame Let Thru Curves ...

Page 31: ...Installation Diagrams 29 ...

Page 35: ...I T E Mechanical Interlock M15404 33 Figure 7 ...

Page 41: ...Installation Diagrams 39 ...

Page 49: ...Installation Diagrams 47 ...

Page 50: ...48 I T E Panelboard Connecting Straps 1 ...

Page 53: ...Installation Diagrams 51 ...