To Set the ICP-B6 Module Address:

1. Plug the programming cable of the DPU or

FPI-32 Programmer/Tester (SensorLINK)

into the two-pin receptacle on the ICP-B6.

(See Figure 2 for location only.)

2. Set the system address for the ICP-B6 by

following the instructions in the FPI-32

(SensorLINK) Programmer/Tester Manual,

P/N 315-090077, or the DPU User's

Manual, P/N 315-033260, as applicable.

Remove all system power before installa-

tion, first battery and then AC. (To power

up, connect the AC first, then the battery.)

All wiring must comply with

national and local codes.

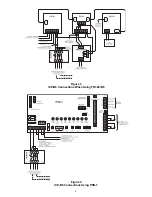

The ICP-B6 should be installed in a UL

listed electrical box. (See Figure 10.)

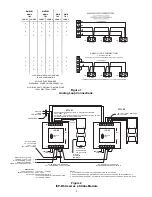

Analog Loop

The ICP-B6 communicates with the MXL

through its analog addressable loops. These

loops are on either the MMB or on the op-

tional ALD-2I module of the MOM-4. They

may be wired for Class A (Style 6) or Class B

(Style 4). Figure 1 shows both wiring types

and the connections to either the MMB or to

the MOM-4 when the ALD-2I module is used.

The table on the following page lists the

maximum output currents allowed.

Installation Instructions

MODEL ICP-B6

Intelligent Control Point

The Model ICP-B6 Intelligent Control Point from

Siemens Industry, Inc. can be used as an

independent, remotely located telephone zone, a

speaker zone (25V or 70.7V RMS), or notification

appliance circuit (NAC), depending on how it is

configured. It communicates through the analog

loop of the MXL/MXLV System.

OPERATION

Up to 12 ICP-B6s can connect to each analog

loop of the MXL/MXLV. These modules must

be connected to the first 12 address locations

on the analog loop.

The 24 VDC power input for each ICP-B6

comes from either the MMB, the PSR, or from

an auxiliary power supply which is power

limited and UL listed for fire protective signal-

ing use and is rated between 24 and 27.3

VDC. Each ICP-B6 can be assigned a 32-

character, custom alphanumeric message.

Each module uses one address on either the

analog loop of the ALD-2I module or the analog

loop of the MMB board. (See Figure 1) The

ICP-B6 is programmable for different usages.

For additional information on the MXL/MXLV

System, refer to the MXL/MXLVManual, P/N

315-092036.

Addressing and Testing

Use the DPU Device Programming Unit or the

FPI-32 Programmer/Tester (SensorLINK) to

program and test the module.

NOTE:

With FPI-32 Rev. 1.3 software, only

1=MXL mode should be used when

programming a device.

P/N 315-095306-10

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario

L6T 5E4 Canada