IQHeat

User manual

21

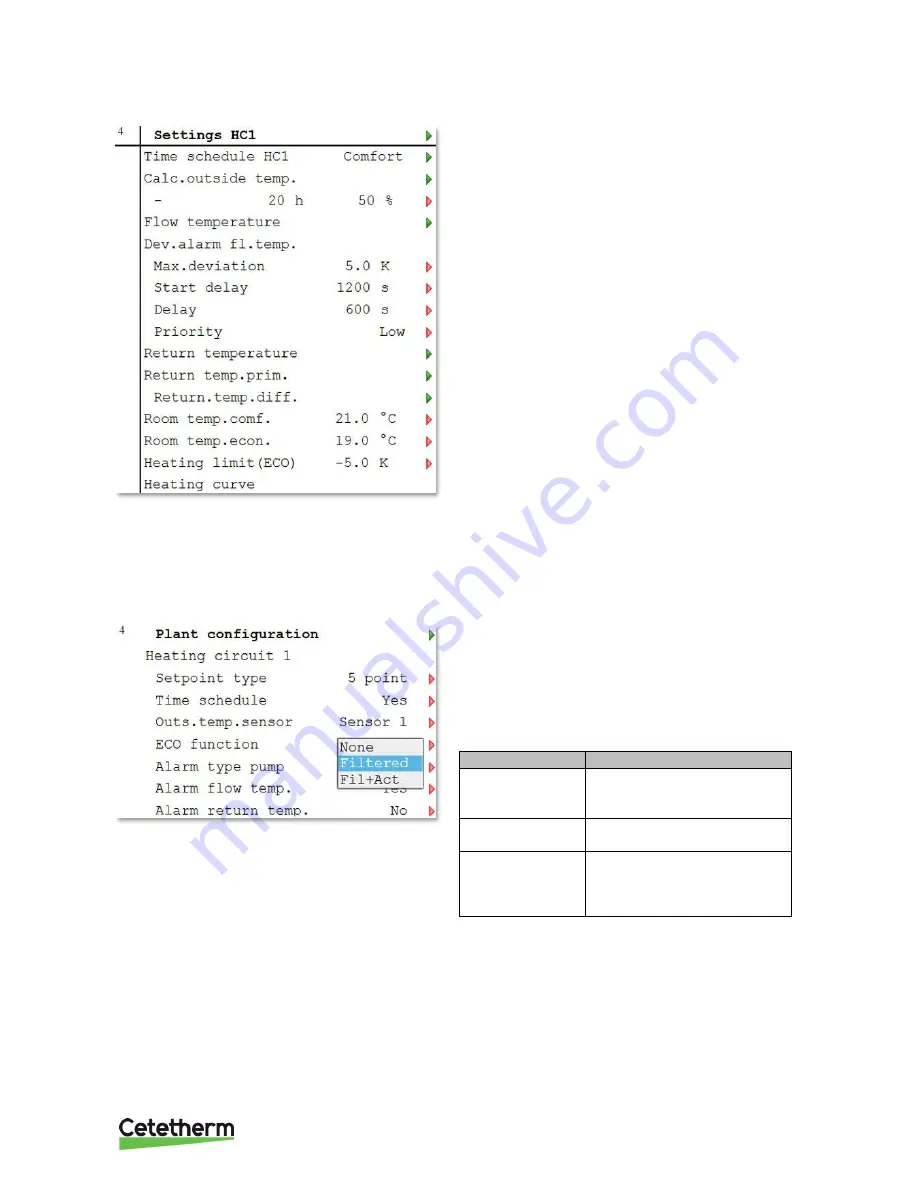

7.5.1

Setting Heating limit (ECO)

NOTE:

Setting the Heating limit (ECO) requires logging

at Service level.

1. Press

Info

to access the Main index.

2. Now select

Commissioning > Plant settings >

Heating circuit1

or just choose

Heating circuit

in the

Main Index

menu.

3. Select

Heating limit (ECO)

and press

OK

.

4. Set the desired value, -

20…0°C

7.5.2

Heat limit function

The temperature that is used as input data for the heating curve is called "use outside temp." The used outside

temperature consists of a combination of the calculated (dampened by the construction time constant, for

example 20 hours) and the current outside temperature. For quick changes it is appropriate to respond in part

directly, without waiting for the full change of the estimated outside temperature.

NOTE:

Activating the heat limit function requires login

at Service level.

1. Press

Info

to access the Main index.

2.

Now select

Commissioning > Plant Config >

Heating circuit(s).

3. Select the

ECO function

and press

OK

.

4. Select preferred mode and press

OK

.

Parameter:

Relates to

None

The ECO mode is not

enabled, the heat is not shut

off during the summer

Filtered

Average value forms the

outside temperature

Fil+Act

The average value of the

dampened outside

temperature and the current

outside temperature

5. Return to Plant Config.

6. Select

Restart

, press

OK

.

7. Select

Execute

and press

OK

.

8. The new settings take effect after restart.