3

Installation

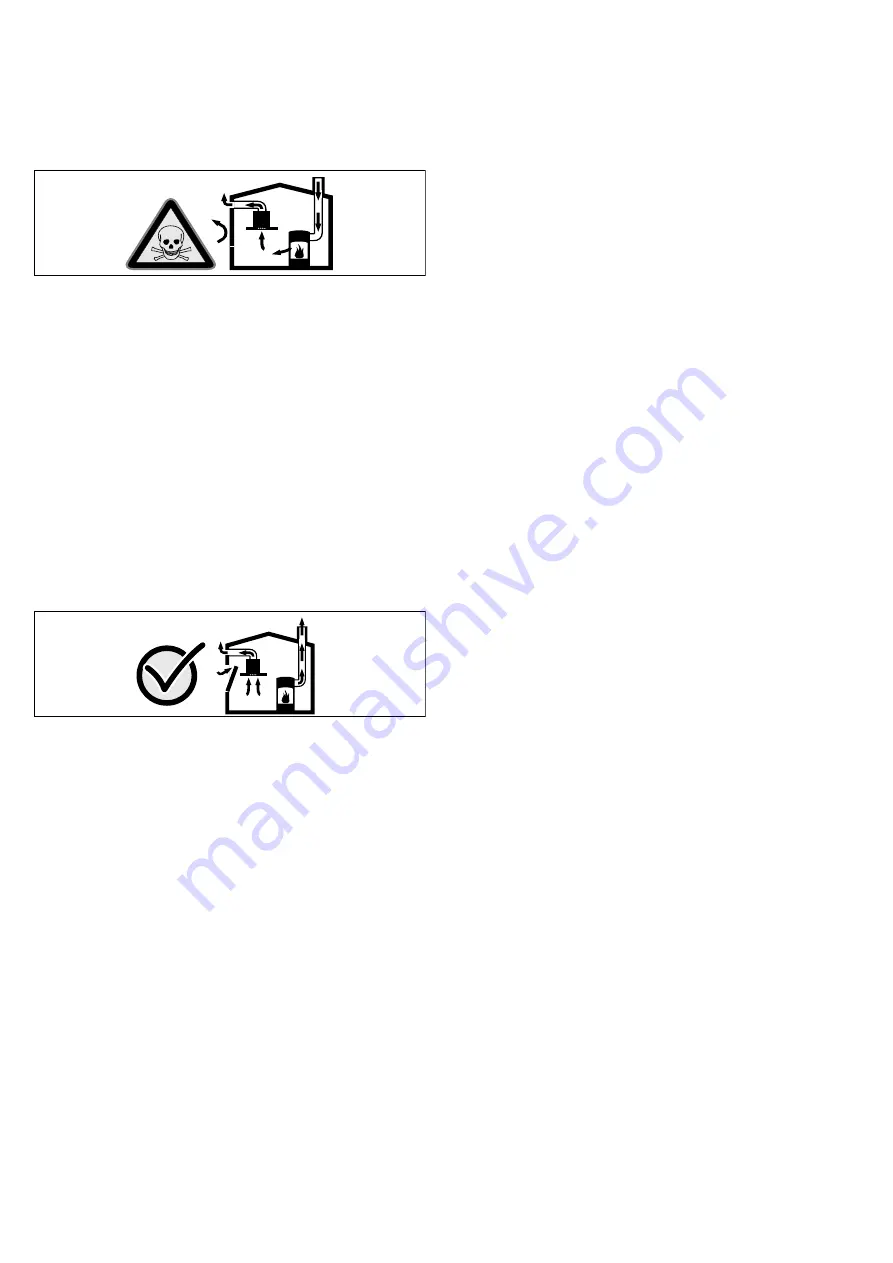

Danger to life! Risk of poisoning!

from combustion gases sucked back in. Never operate the

appliance in the exhaust air mode at the same time as a room

air-dependent heat-producing appliance unless an adequate

supply of fresh air is ensured.

Room air-dependent heat-producing appliances (e.g. gas, oil,

wood or coal-operated heaters, continuous flow heaters or

water heaters) obtain combustion air from the room in which

they are installed and discharge the exhaust gases into the

open through an exhaust gas system (e.g. a chimney).

In combination with an activated vapour extractor hood, room

air is extracted from the kitchen and neighbouring rooms - a

partial vacuum is produced if not enough fresh air is supplied.

Toxic gases from the chimney or the extraction shaft are

sucked back into the living space.

■

Adequate incoming air must therefore always be ensured.

■

An incoming/exhaust air wall box alone will not ensure

compliance with the limit.

Safe operation is possible only whenever the partial vacuum in

the place where the firing equipment is installed does not

exceed 4 Pa (0.04 mbar). This can be achieved whenever the

air needed for combustion is able to enter through openings

that cannot be sealed, for example in doors, windows,

incoming/exhaust air wall boxes or by other technical means.

In any case, consult your responsible chimney sweep. He is

able to assess the house's entire ventilation setup and will

suggest the suitable ventilation measures to you.

Unrestricted operation is possible if the vapour extractor hood

is operated exclusively in the recirculation mode.

Risk of fire!

from flying sparks. Do not install the appliance above a solid

fuel heater (e.g. wood or coal) unless a closed, non-removable

cover is available.

Caution!

Risk of damage from heat accumulation due to an overly

narrow gap between the appliance and high-sided unit or wall.

Only one side of the appliance may be installed directly next to

a high-sided unit or a wall. Distance between the appliance and

wall or high-sided unit must be at least 50 mm.

The specified safety distances must be observed. Also observe

the specifications for your cooking appliance. If gas and electric

hobs are operated together, the largest specified distance

applies.

The width of the extractor hood must correspond at least with

the width of the hob.

For the installation, observe the currently valid building

regulations and the regulations of the local electricity and gas

suppliers.

Risk of electric shock!

from damaged connection cable. Do not kink or pinch

connection cable during installation.

Risk of fire, risk of injury!

from damaged connection cable. A damaged connection cable

must be replaced by a qualified technician (electrician).

Risk of injury!

From sharp edges during installation. Always wear protective

gloves while installing the appliance.

Risk of injury!

from a falling appliance. All safety screws and safety caps must

be firmly fitted.

Using the appliance

Risk of burns!

from hot appliance when used with cooking appliances. Keep

children away and ensure appliance is used properly.

Risk of injury, risk of damage!

from objects placed on the appliance. Never place objects on

the appliance.

Risk of fire, risk of burns!

if gas hotplates not covered with cooking utensils. Always use

gas hotplates with appropriate cooking utensils. Regulate flame

to ensure that it does not lick over the cooking utensil.

Risk of burns, risk of damage!

if several gas hotplates are operated simultaneously. Never

operate two gas hotplates simultaneously on the highest flame

for longer than 15 minutes. The housing will become very hot

due to the intense heat.

Please note:

One large burner of more than 5 kW (wok) is

equivalent to the power of two gas burners.

Risk of fire!

■

from grease deposits in the metal mesh grease filter. Never

work under the appliance with a naked flame (e.g.

flambéing). Always operate the appliance with the metal

mesh grease filter. Regularly clean the metal mesh grease

filter.

■

from overheated fats and oils. Heat fats and oils under

constant supervision only. Never extinguish fire with water,

always use a fire blanket, lid or plate.

Caution!

Risk of damage due to corrosion. Always switch on the

appliance while cooking to avoid condensation. Condensate

can produce corrosion damage.

Risk of injury!

from the glare of an LED in risk group 1. Do not look directly

into the LED light for longer than 100 seconds while it is

switched on.

Summary of Contents for LC98BC540

Page 1: ... HQ QVWUXFWLRQV IRU LQVWDOODWLRQ DQG XVH WUDFWRU KRRG ...

Page 11: ...11 ...