5

Control panel variant 2

Control panel variant 3

Switching on the fan: variant 1

Press the On/Off button.

The fan setting can be increased with the

@

button or reduced

with the

A

button.

Intensive setting

You can use the intensive setting if there is a large build-up of

odours and fumes/vapours.

Press the

@

button repeatedly until

˜

or

›

appears in the

display.

The run time is limited. The fan is then automatically reduced to

a lower fan setting. You can switch back manually at any time.

Switching on the fan: variants 2 and 3

Increase or reduce the fan settings by pressing buttons 1, 2

or 3.

Intensive setting: variant 3

Press the

˜

button.

Lighting

The lighting can be switched on and off independently of the

fan.

Installing and removing the filter

:

Risk of burns, risk of electric shock!

from appliance. Always leave appliance to cool down before

cleaning or servicing. Switch off fuse or pull out mains plug.

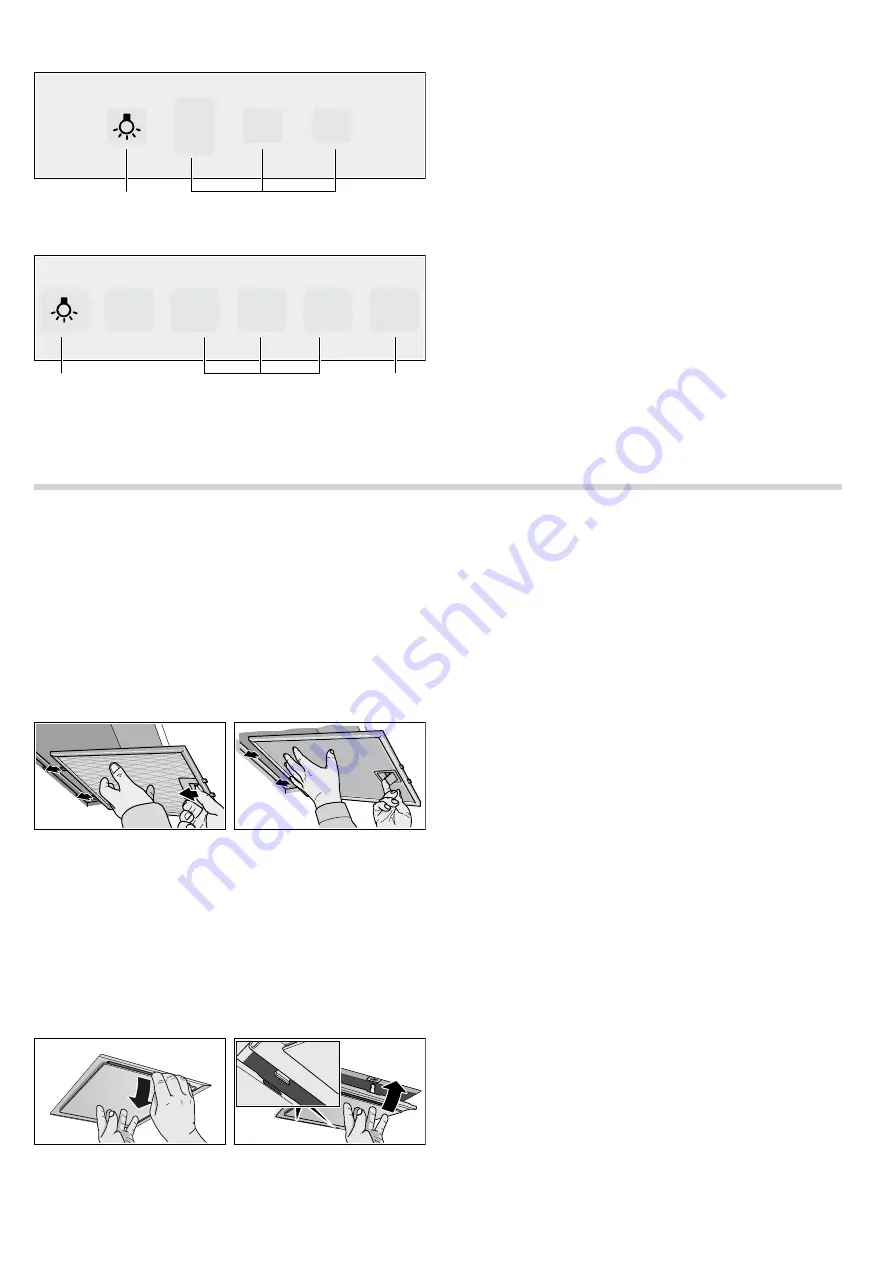

Removing metal mesh grease filter

1.

Open the lock and fold down the metal mesh grease filter.

While doing this, place the other hand under the metal mesh

grease filter.

2.

Take the metal mesh grease filter out of the holder.

With edge extraction

1.

Pull metal mesh grease filter downwards.

While doing this, place the other hand under the metal mesh

grease filter.

2.

Take the metal mesh grease filter out of the holder.

Notes

■

Grease can accumulate in the bottom of the metal mesh

grease filter.

■

Do not hold the metal mesh grease filter at an angle,

otherwise grease will drip out.

Installing the metal mesh grease filter

1.

Insert the metal mesh grease filter.

While doing this, place the other hand under the metal mesh

grease filter.

2.

Fold up the metal mesh grease filter, locking it in place.

/LJKW

2Q2II

)DQVHWWLQJV

3

/LJKW

2Q2II

)DQVHWWLQJV

,QWHQVLYH

VHWWLQJ

Summary of Contents for LC98BC540

Page 1: ... HQ QVWUXFWLRQV IRU LQVWDOODWLRQ DQG XVH WUDFWRU KRRG ...

Page 11: ...11 ...