6

Cleaning and care

:

Risk of burns, risk of electric shock!

from appliance. Always leave appliance to cool down before

cleaning or servicing. Switch off fuse or pull out mains plug.

Caution!

■

Risk of damage due to ingress of humidity into the electronic

circuitry. Never clean operator controls with a wet cloth.

■

Surface damage due to incorrect cleaning. Clean stainless

steel surfaces in the grain direction only. Do not use any

stainless steel cleaners for operator controls.

■

Surface damage due to strong or abrasive cleaning agents.

Never use strong and abrasive cleaning agents.

Cleaning the appliance surface

Suitable cleaning agents and care products for your appliance

can be purchased via the Hotline or from the Online Shop (see

the start of the instructions for use).

Note:

The appliance surface and controls are scratch-sensitive.

Observe the warranty regulations in the enclosed service

booklet and the following cleaning instructions:

■

Clean the surfaces with a soft, damp cloth, washing-up liquid

or a mild window cleaner. Soften dried dirt with a damp cloth.

Do not scratch.

■

Dry cloths, abrasive sponges, scouring agents, cleaning

agents containing sand, soda, acid, chlorine or any other

aggressive substances are not suitable.

■

Clean stainless steel surfaces in the direction of the grain

only.

■

Do not use stainless steel cleaner or wet cloths for the

controls.

Cleaning the metal mesh grease filters

The inserted metal mesh grease filters absorb the grease

particles from the kitchen fumes. Clean the metal mesh grease

filters under normal use (1 to 2 hours daily) approx. every three

months.

Notes

■

Do not use any aggressive, acidic or alkaline cleaning

agents.

■

When cleaning the metal mesh grease filters, also clean the

holder for the metal mesh grease filters in the appliance

using a damp cloth.

■

The metal mesh grease filters can be cleaned in the

dishwasher or by hand.

In the dishwasher:

Note:

If the metal mesh grease filters are cleaned in the

dishwasher, slight discolouration may occur. This has no effect

on the function of the metal mesh grease filters.

■

Do not clean heavily soiled metal mesh grease filters together

with utensils.

■

Place the metal mesh grease filters loosely in the dishwasher.

The metal mesh grease filters must not be wedged in.

By hand:

Note:

You can use a special grease solvent for stubborn dirt. It

can be ordered via the Online Shop.

■

Soak the metal mesh grease filters in a hot soapy solution.

■

Clean the filters with a brush and then rinse them thoroughly.

■

Leave the metal mesh grease filters to drain.

Replacing bulbs

:

Risk of burns, risk of electric shock!

from defective bulbs. Switch off the fuse or pull out the mains

plug. Always replace defective bulbs immediately (leave bulbs

to cool down first) to prevent the remaining bulbs from

overloading.

Important

Only use a bulb of the same type and same power

(see the bulb holder or rating plate inside the appliance) – to

do this, remove the metal mesh grease filter.

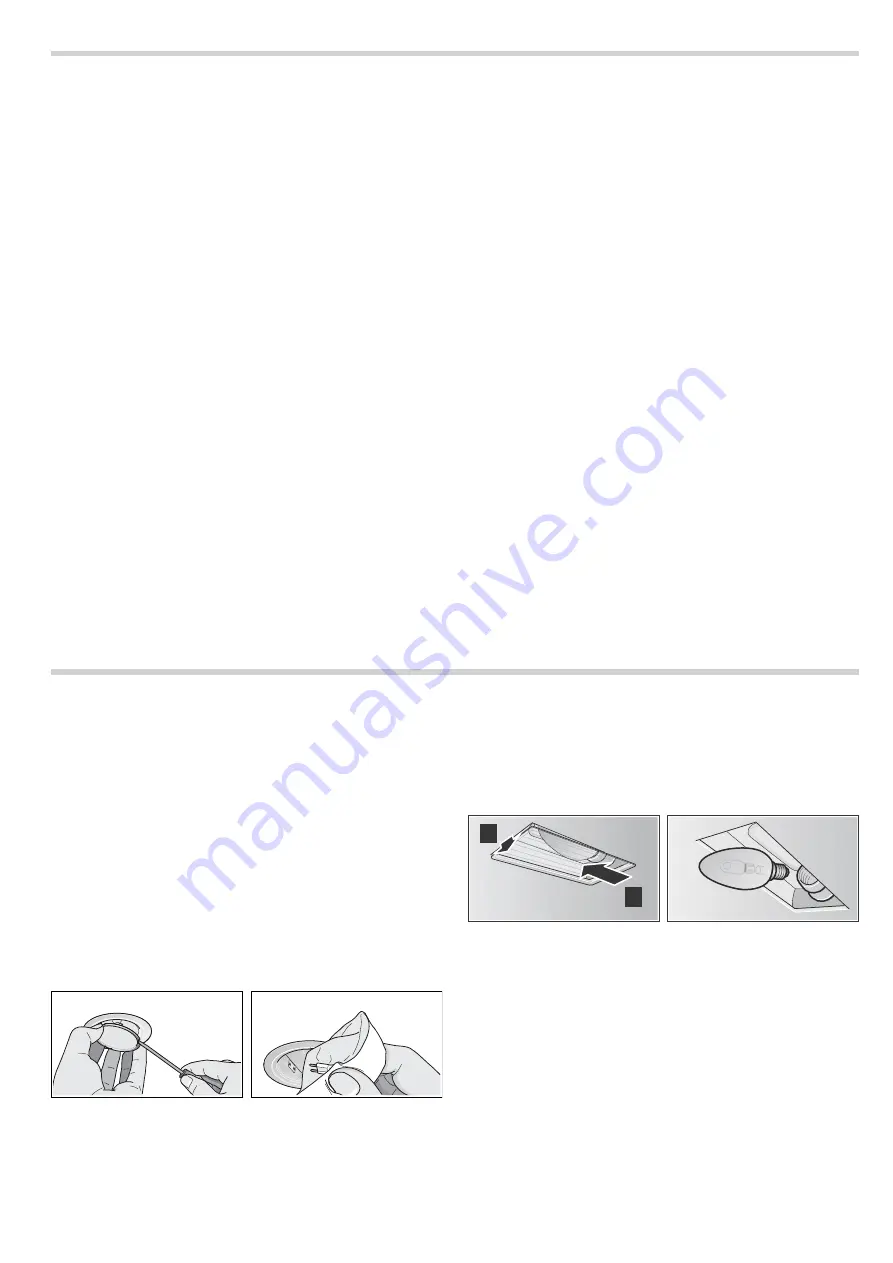

Replacing halogen bulbs

Note:

When inserting halogen bulbs, do not touch the glass

tube. Use a clean cloth to insert the halogen bulbs.

1.

Carefully remove the bulb ring using a suitable tool.

2.

Pull out the bulb and replace it with a bulb of the same type.

3.

Insert the bulb cover.

4.

Insert the mains plug or switch on the fuse again.

Replacing filament bulbs

1.

Lift the bulb cover slightly and push towards the outside of

the appliance.

2.

Unscrew the bulb and replace it with a bulb of the same type.

3.

Insert the bulb cover.

4.

Insert the mains plug or switch on the fuse again.

LED lights

Defective LED lights may be replaced by the manufacturer, their

customer service or a qualified technician (electrician) only.

:

Risk of injury!

from the glare of an LED in risk group 1. Do not look directly

into the LED light for longer than 100 seconds while it is

switched on.

Summary of Contents for LC98BC540

Page 1: ... HQ QVWUXFWLRQV IRU LQVWDOODWLRQ DQG XVH WUDFWRU KRRG ...

Page 11: ...11 ...