10

Connecting the pipes

Note:

If using an aluminium pipe, smooth the connection area

beforehand.

Exhaust-air pipe Ø 150 mm (recommended size)

Attach the exhaust-air pipe directly to the air-pipe connector

and seal.

Exhaust-air pipe Ø 120 mm

1.

Attach the reducing connector directly to the air-pipe

connector.

2.

Attach the exhaust air pipe to the reducing connector.

3.

Seal both joints appropriately.

Electrical connection

:

Risk of electric shock!

from damaged connection cable. Do not kink or pinch

connection cable during installation.

The required connection data can be found on the rating plate

inside the appliance; to do this, remove the metal mesh grease

filter.

Length of the cable: approx. 1.30 m

This appliance complies with the EC interference suppression

regulations.

This appliance may be connected to a correctly installed

earthed socket only.

Attach the earthed socket preferably inside the flue duct.

■

The earthed socket should be connected via its own circuit.

■

If the earthed socket is no longer accessible following

installation of the appliance, a disconnecter must be fitted as

for a permanent connection.

If a permanent connection is required, the installation must

feature an all-pole disconnecter (circuit breakers, fuses and

contactors) with a min. 3 mm contact opening. The permanent

connection may be installed by an electrician only.

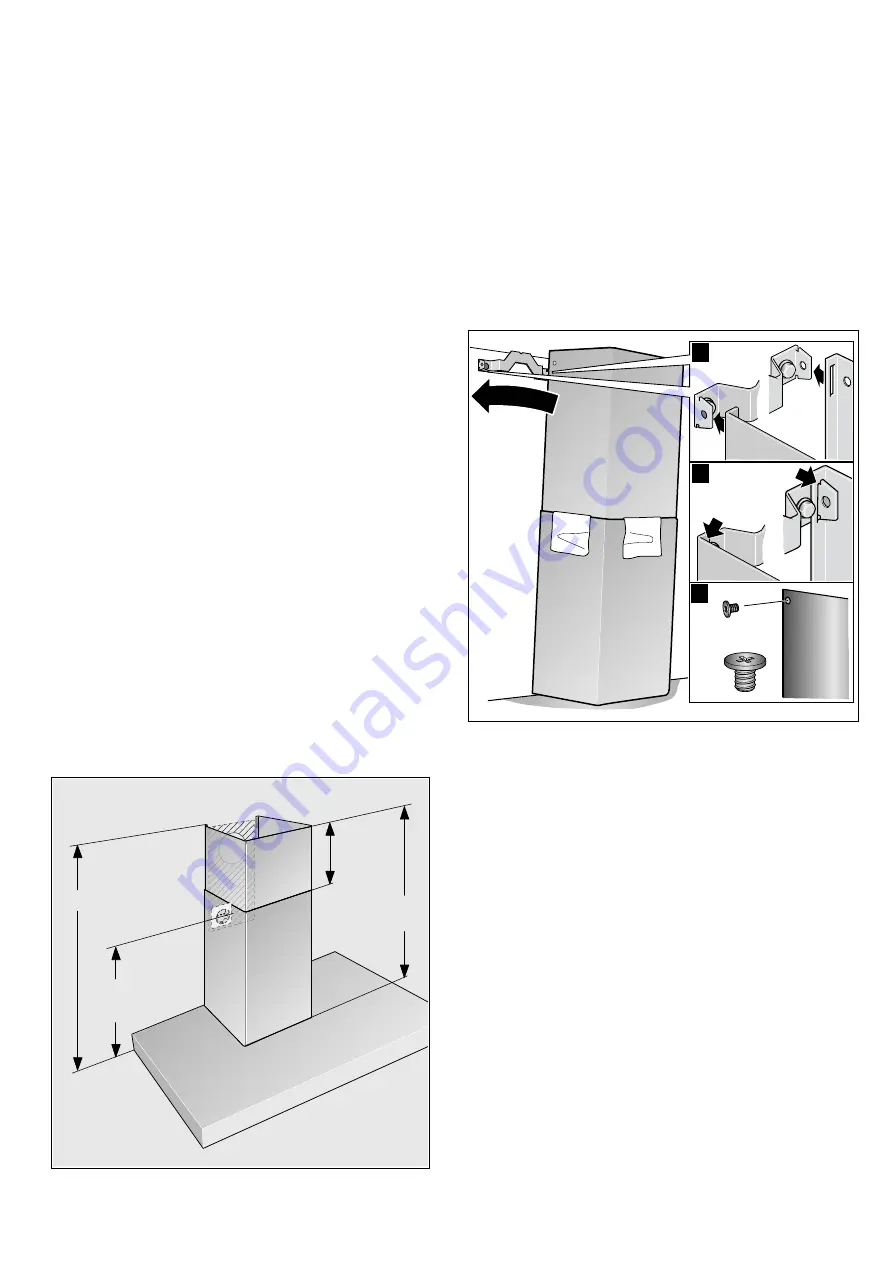

Attaching the flue duct

:

Risk of injury!

From sharp edges during installation. Always wear protective

gloves while installing the appliance.

1.

Separate the flue ducts.

To do this, remove the adhesive tape.

2.

Remove the protective foil from both flue ducts.

3.

Push one flue duct into the other.

Notes

■

To prevent scratches, use paper to protect the edges of the

outer flue duct.

■

Slots of the inner flue duct downwards.

4.

Place the flue ducts on the appliance.

5.

Push the inner flue duct upwards and attach it to the fixing

brackets on the left and right.

¨

6.

Press the flue duct downwards until it engages.

©

7.

Screw the flue duct to the sides of the fixing bracket using

two screws.

ª

PLQ

PP

PLQ

PP

PLQ

PP

PD[PP

[

$

%

&

Summary of Contents for LC98BC540

Page 1: ... HQ QVWUXFWLRQV IRU LQVWDOODWLRQ DQG XVH WUDFWRU KRRG ...

Page 11: ...11 ...