87/116

Smart Infrastructure

Basic Documentation LME7...

CC1P7105en

13 Operation via AZL2

24.07.2020

13.9

Operating variants of the parameters

The parameters stored in the LME7 can be displayed and changed at parameter level.

VSD

A

F

>1 s

Press button combination

VSD

A

F

to display

000: Int

.

With

, select the parameter group

100:

PArA

.

With

, select the parameter group

200:

PArA

.

Pressing the

/reset

button takes you to

parameter

226:

Preignition time.

13.9.1

Parameters without index, with direct display

13.9.1.1.

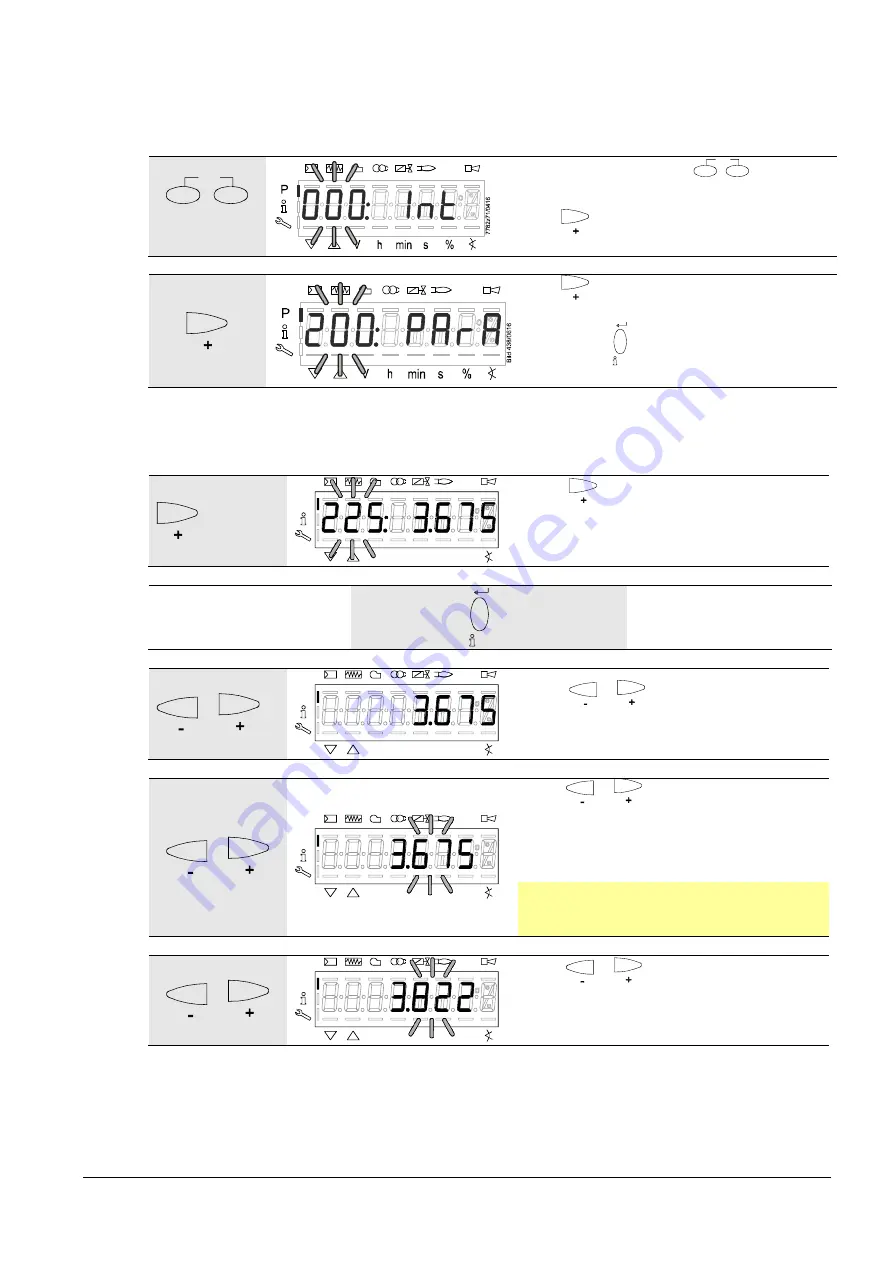

Example of parameter 225 (prepurge time) on the parameter level

P

V

h min s

%

B

ild

166

/1

1

0

7

Press

for

prepurge time

.

Display: Parameter

225:

blinks, value

3.675

does not.

/reset

or

P

V

h min s

%

B

ild

167

/1

1

0

7

Press

or

for editing mode.

Display:

3.675

or

P

V

h min s

%

B

ild

168

/1

107

Press

or

to shift the former prepurge

time to change mode one place to the left.

Display: Prepurge time

3.675

blinks.

Note:

To detect display errors, the value appears

one place shifted to the left.

or

P

V

h min s

%

B

ild

169

/1

107

Press

or

for the required prepurge

time.

Display: Prepurge time

3.822

blinks.