5/16

Building Technologies Division

CC1N7138en

18.05.2016

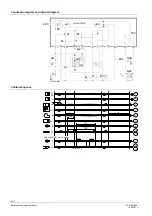

Function

Burner control is reset

Reset

button

«EK1»

or

«EK2»

not used

All contacts in the line are closed, heat demand

No

undervoltage

Flame detector is darkened and there is no extraneous light

Safety shutdown from the operating position takes place should mains voltage drop

below about AC 165 V (with U

N

= AC 230 V)

Restart is initiated when mains voltage exceeds about AC 175 V

(with U

N

= AC 230 V)

If the oil preheater

’

s release contact does not close within 10 minutes, a non-alterable

lockout takes place.

After 24 hours of continuous operation at the latest, the burner control will initiate

automatic safety shutdown followed by a restart.

If a non-alterable lockout occurs, the outputs for the fuel valves, the burner motor and the

ignition equipment are always immediately deactivated (<1 second).

In the event of a non-alterable lockout, the LMO remains locked and the red signal lamp

(LED) lights up permanently.

The burner control can immediately be reset.

This status is also maintained in the case of a mains failure.

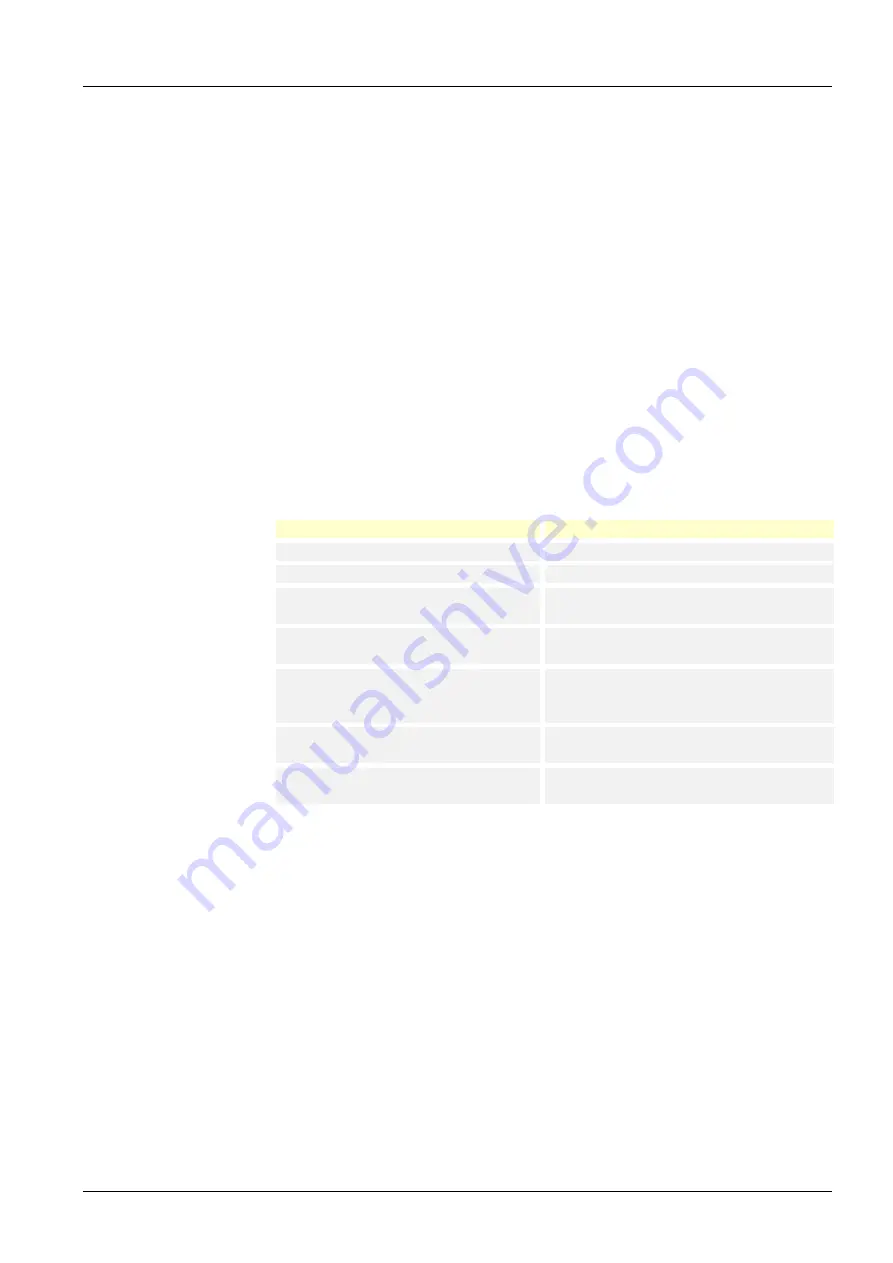

Cause

Response

Mains failure

Restart

Voltage below undervoltage threshold

Safety shutdown, followed by restart

Extraneous light during «t1», 5 s before

«BV1» release

Non-alterable lockout at the end of the

prepurge time (t1)

Extraneous light during «tw»

Start prevention, a non-alterable lockout

occurs after a maximum of 40 seconds

No flame at the end of «TSA»

Non-alterable lockout at the end of the

safety time (TSA), blink code 2, see

Control

sequence

Flame is lost during operation

Maximum of 3 repetitions, then a non-

alterable lockout occurs

Oil preheater’s release contact does not

close within 10 min.

Non-alterable lockout

After a non-alterable lockout, a reset can be carried out immediately.

To do this, press the lockout reset button for about 1 second (<3 seconds). The LMO...

can only be reset when all contacts in the line are closed and when there is no

undervoltage.

If the flame is lost during the safety time (TSA), the burner will be reignited before the

end of the safety time (TSA) at the latest. This means that several ignition attempts can

be made within the safety time (TSA), see

Program sequence

.

If the flame is lost during operation, a maximum of 3 repetitions can be carried out.

Each time the flame is lost during operation, a non-alterable lockout will be initiated.

The repetition count is restarted each time controlled switching on by «R» takes place.

Postpurging is only possible when the oil preheater contact is closed or when the wire

link between terminals 3 and 8 is fitted.

A demand for heat via «R» during postpurge time «t8», implicates an interruption of

postpurging, followed by new start.

Preconditions for

startup

Undervoltage

Time supervision

oil preheater

Controlled intermittent

operation

Control sequence in

the event of fault

Resetting the

burner control

Ignition program with

LMO 64.302...

Limitation of repetitions

Postpurging