Technical

Instructions

LMV

Series

Document

No.

LV5

‐

1000

Section

5

Page

8

SCC

Inc.

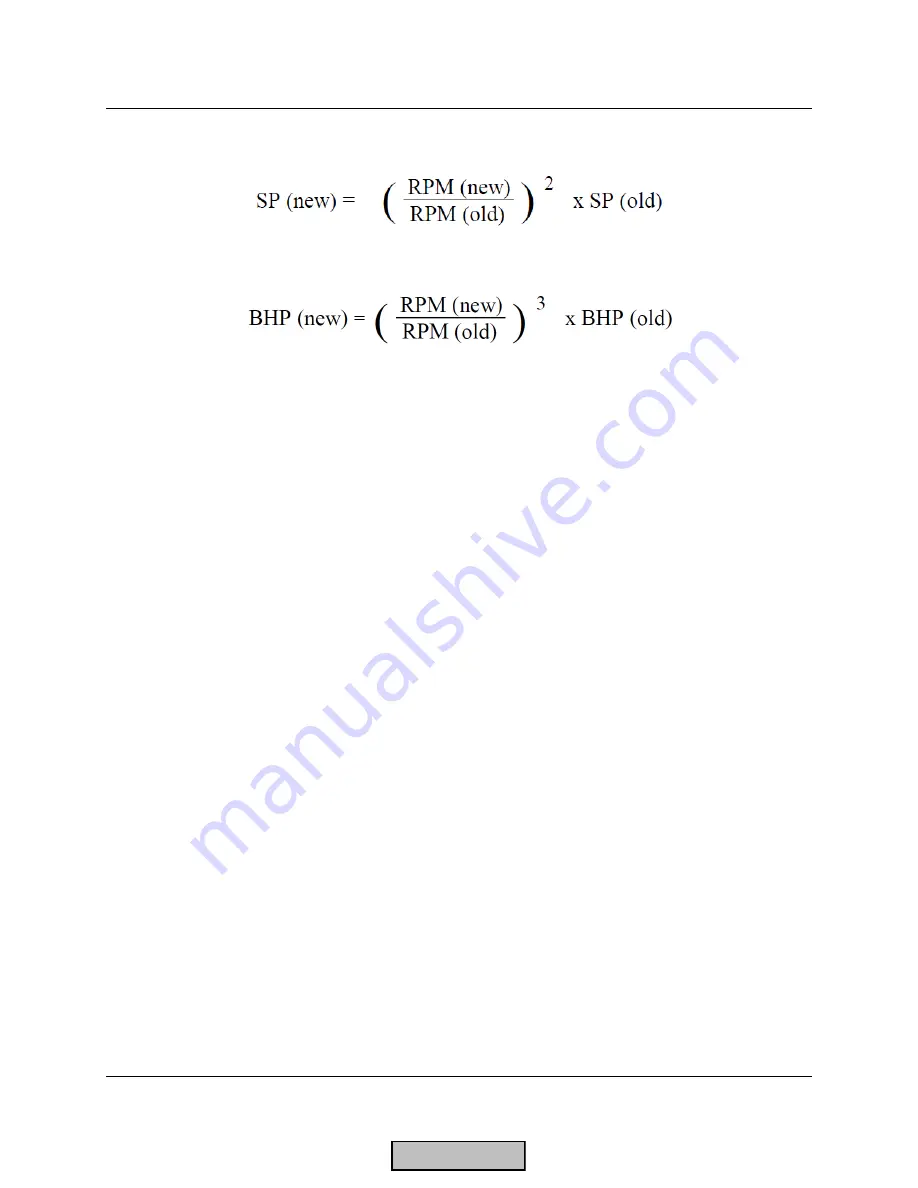

2.

The

static

output

pressure

of

the

blower

(SP)

varies

by

the

square

of

the

change

in

RPM:

3.

The

required

brake

horsepower

of

the

blower

(BHP)

varies

by

the

cube

of

the

change

in

RPM:

Example:

A

blower

spinning

at

1750

RPM

produces

10

in

WC

of

static

pressure,

4500

CFM

of

flow,

and

requires

20

BHP.

What

happens

if

the

RPM

is

increased

to

2750

RPM?

Assumptions:

Air

damper

is

wide

open,

and

system

effects

(such

as

the

restriction

due

to

the

boiler's

heat

exchanger,

the

burner’s

diffuser,

etc...)

are

not

taken

into

account.

Flow:

CFM

(new)

=

(2750

/

1750)

*

4500

=

7071

CFM

Pressure:

SP

(new)

=

(2750

/

1750)

2

*

10

=

24.7

in

WC

Power:

BHP

(new)

=

(2750

/

1750)

3

*

20

=

78

BHP

Configuring

VFDs

for

use

with

the

LMV52

Modern

VFDs

typically

have

hundreds

of

parameters

that

can

be

set

to

tailor

the

VFD

to

a

specific

application.

As

mentioned

earlier,

there

are

also

at

least

a

hundred

different

manufacturers

of

VFDs,

each

of

which

have

their

own

unique

parameter

list.

Due

to

these

two

factors,

SCC

Inc.

offers

pre

‐

programmed

VFDs

that

can

be

purchased

with

the

VFD

parameters

set

up

for

use

with

an

LMV52.

If

a

VFD

for

use

with

an

LMV52

is

purchased

and

programmed

independently,

the

following

points

will

serve

as

a

general

guideline

for

programming

the

VFD

for

the

LMV52

application.

Note

that

this

guideline

is

necessarily

general

due

to

the

variety

of

VFDs

offered

in

the

marketplace.

1.

If

a

Vector

VFD

is

used

(recommended),

set

the

"Control

Method"

to

Open

Loop

Vector

mode

or

equivalent.

2.

The

stopping

method

(after

the

run

/

stop

contact

is

opened)

should

be

set

to

"Coast

to

Stop"

to

let

the

motor

coast

to

a

stop

after

post

‐

purge.

3.

Reverse

operation

(the

ability

to

reverse

the

motor

with

an

input)

should

be

disabled.

4.

Configure

the

VFD

to

accept

an

external

run

/

stop

signal

via

the

dry

contact

on

the

LMV52.

HOME

Summary of Contents for LMV 5 Series

Page 2: ...Intentionally Left Blank ...

Page 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Page 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Page 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Page 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Page 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Page 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Page 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Page 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Page 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Page 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Page 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Page 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Page 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Page 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Page 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Page 373: ...Intentionally Left Blank ...