11

3 Operating the SAMMS-LV Device

3 Operating the SAMMS-LV Device

This section explains how to operate the SAMMS-LV device.

Operation of the device requires that the unit have control power

(12VAC) applied to terminals 5-6. Most operations also require

use of the Hand-Held Communicator (HHC). Use of the HHC is

described in detail in section 3.27.

3.1 Password Protection

Changing the settings of the SAMMS-LV device requires the

use of the Hand-Held Communicator (HHC) in the program

mode. To access the program mode, the user needs a

password. The SAMMS-LV device is shipped from the factory

with the password 0000. This password can be changed by

the user as described in section 3.28.1. Display of data using

the HHC does not require use of a password.

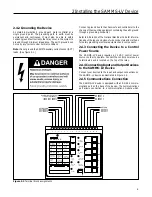

3.2 Using the Reset/Test Push Button

The Reset/Test pushbutton is located at the bottom center of

the front panel of the SAMMS-LV device as illustrated in Figure

3.1. You press this pushbutton to manually reset the SAMMS-LV

device after a fault or a trip condition occurs so that the motor

can be restarted. You can also use the Reset/Test pushbutton

to perform a lamp test or an overload relay test.

3.2.1 Performing a Lamp Test

To test the diagnostic LEDs, the control LEDs and the light bars

on the front panel, use the following procedure:

1. Press and hold the Reset/Test pushbutton for one to two

seconds.

2. Release the Reset/Test pushbutton. (All LEDs and light bars

on the front panel illuminate for two seconds.)

If a fault or trip condition exists when you press the Reset/Test

pushbutton, the device performs a reset instead of a lamp test.

3.2.2 Performing an Overload Relay Test

You may perform an overload relay test whenever the motor is

stopped. Use the following procedure to perform an overload

relay test.

1. Press and hold the Reset/Test pushbutton for at least the

duration of the class time. The class time is set by accessing

function F7. If you need to know how to access function F7,

see Section 3.28. If you release the Reset/Test pushbutton

before the duration of the class time, the device performs a

lamp test. If a fault or trip condition exists when you press the

Reset/Test pushbutton, the device performs a reset instead

of a lamp test.

2. Continue to hold down the Reset/Test pushbutton. After

reaching the class time duration, the Impending Trip and the

Phase Unbalance LEDs illuminate.

3. Release the Reset/Test pushbutton. The Impending Trip

and Phase Unbalance LEDs go off, and the Overload Trip

LED illuminates for two seconds. If the SAMMS-LV device

is tripped, it is automatically reset at the end of the overload

relay test.

Note that this test checks the electronic circuitry, but does not

replace a test in which actual power current is passed through

the primary circuit.

Use the following procedure to reset the SAMMS-LV device

after a trip event.

1. Press the Reset/Test pushbutton.

2. Release the Reset/Test pushbutton. The device resets the

alarm LEDs. If the motor has cooled sufficiently, you can

restart the motor.

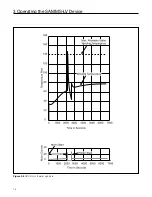

3.3 Motor Control

You can configure the SAMMS-LV device to perform many

motor starting and control functions. These functions include

basic across-the-line, to more complicated reversing, two-

speed, and reduced-voltage starting. The SAMMS-LV device

stores in its memory the executable code representing the

ladder diagram for the users control application. The SAMMS-LV

device and ladder diagram code replace the conventional

control logic defined by wired interconnection of electrome-

chanical timers, control relays, pushbuttons, selector switches,

and pilot lights. A library of over 70 standard ladder diagrams

available for the SAMMS-LV device covers most applications.

In addition to the standard ladders, you can construct custom

ladder diagrams, using optional software, to handle special

applications.

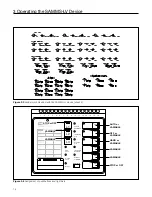

Figures 3.2 and 3.3 illustrate the ladder symbols representing

input and output devices available for the SAMMS-LV device.

The circular symbols represent output devices such as contactor

coil drivers, pilot LEDs on the front panel of the SAMMS-LV

device, software time-delay relays and software control relays.

All other symbols represent input devices such as software

auxiliary contacts, remote AC inputs, front-panel pushbuttons,

and software timer instantaneous and timed contacts.

1 2 3

4 5 6 7 8 9 10 11 12 13

14 15 16

Figure 3.1

Front view of SAMMS-LV