Page 14

Milltronics ILE-37 – INSTRUCTION MANUAL

7ML19985CW01

Troubleshooting

Every Milltronics ILE-37 sensing head is subjected to extensive quality assurance

procedures to ensure the highest possible degree of quality, reliability, and performance

is achieved.

The following listing indicates the probable cause, and proper course of action to be

taken should the specified fault symptom occur.

Symptom

Cause

Action

Integrator rate display doesn’t

change when sensing plate is

moved.

Wrong or bad integrator

connection.

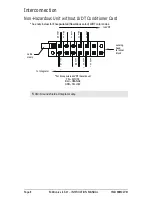

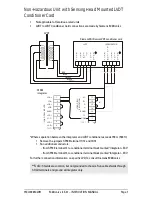

Refer to INSTALLATION/

Interconnection

Viscous damper cover in

shipping position.

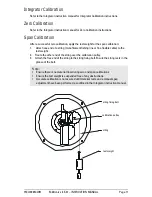

Refer to INSTALLATION/

Viscous Damper.

Integrator not prepared for

operation.

Program and calibrate the

integrator.

Span adjustment does not have

enough range.

Range spring not suited to

application

Refer to RANGE SPRINGS.

Measurement results are not

repeatable.

Sensing head not level.

Refer to INSTALLATION and

CALIBRATION/Sensing Head

Level Test

Moving beam travel is

mechanically limited.

Ensure moving beam does not

hit travel stops between –20%

and 150% flowrates.

Leaf springs are damaged.

Replace leaf springs, re-

calibrate Flowmeter and

Integrator.

Material flow patterns vary.

Refer to the flowmeter

instruction manual

APPLICATIONS section.

Accuracy varies with material

flowrate.

Non-linear operation

Refer to LINEARITY.

Summary of Contents for milltronics ILE-37

Page 1: ...Instruction Manual September 2003 ILE 37 milltronics ...

Page 4: ...ii ...

Page 25: ...Notes ...

Page 26: ...Notes ...

Page 27: ......