7SG163 Ohmega 300 Series Maintenance

2 Troubleshooting Guide

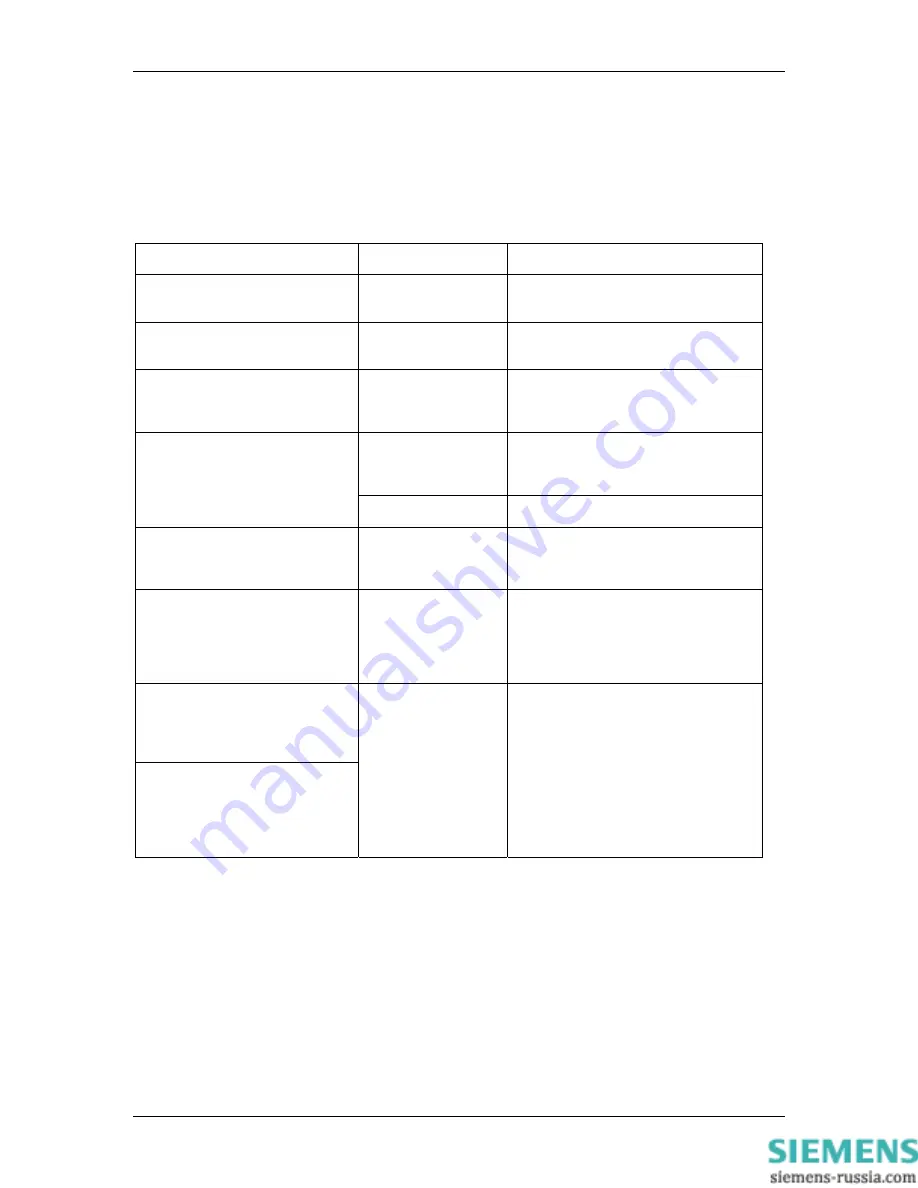

The following table describes the action of the relay under various conditions, and suggested remedial

actions when problems are encountered.

If problems are being experienced and the suggested action does not work, or the problem is not detailed

below, then please contact Siemens.

SYMPTOM PROBLEM

ACTION

LCD Screen is faint or difficult to

read.

Contrast too low

Press TEST/RESET & UP Button

simultaneously

LCD Screen is dark or has lines

across it.

Contrast too high

Press TEST/RESET & DOWN Button

simultaneously

Protection Healthy LED not lit,

LCD blank, Backlight off & No

Flag LEDS lit.

Relay is not powered

up

Check Auxiliary DC supply is available.

Check connections on rear of relay.

Power supply is too

low.

Check the magnitude of the input DC

voltage. Ensure it is within the relay’s

working range of 37.5 to 137.5 V

Relay LCD displays “PSU alarm

asserted, supply out of limits”

Internal ribbon cable

connection not made.

Check ribbon connection cable to

module A is correctly attached.

Protection Healthy LED blinking,

Messages & cursor blocks

flashing across the LCD screen

Internal ribbon

connections not made

correctly

Check ribbon connection cables to

each module are correctly attached.

Relay displays “Number of inputs

or outputs changed… Relay must

cold start… Settings will be

defaulted…Please press enter”

Relay has performed

a cold start due to a

perceived change in

hardware.

If the hardware has not been changed

(i.e. status input/relay output card

added or removed) then there may be a

problem with the hardware.

Contact Siemens

Protection Healthy LED is

flashing.

Protection Healthy Output contact

is not energised.

Protection Healthy LED is steady,

and LCD screen displays ohmega

symbols (

Ω

).

Protection Healthy Output contact

is not energised.

Watchdog Operated:

Hardware or

Software Fault

Contact Siemens

©2010 Siemens Protection Devices Ltd

Chapter 10 Page 4 of 6