Technical Instructions

GBB/GIB Series Non-spring Return, 24 Vac, Modulating Control

Document Number 155-176P25

June 22, 2015

Page 10

Siemens Industry, Inc.

Sizing

The number of actuators required depends on several factors. To determine the quantity

of actuators required for the installation, do the following:

1. Obtain damper torque ratings (ft-lb/ft

2

or Nm/m

2

) from the damper manufacturer.

2. Determine the area of the damper.

3. Calculate the total torque required to move the damper:

Total Torque = Torque Rating × Damper Area

4. Select the total quantity of actuators required:

Number of actuators =

Total Damper Torque required

SF x Actuator Torque (Refer to Specifications)

1

1

Safety Factor: When calculating the number of actuators required, a safety factor

should be included for unaccountable variables such as slight misalignments, aging

of the damper, etc. A suggested safety factor is 0.80 (or 80% of the rated torque).

Mounting and

Installation

Figure 18. Acceptable NEMA 2

Positions.

Figure 19. Acceptable NEMA 2 Position

for Tandem Applications.

•

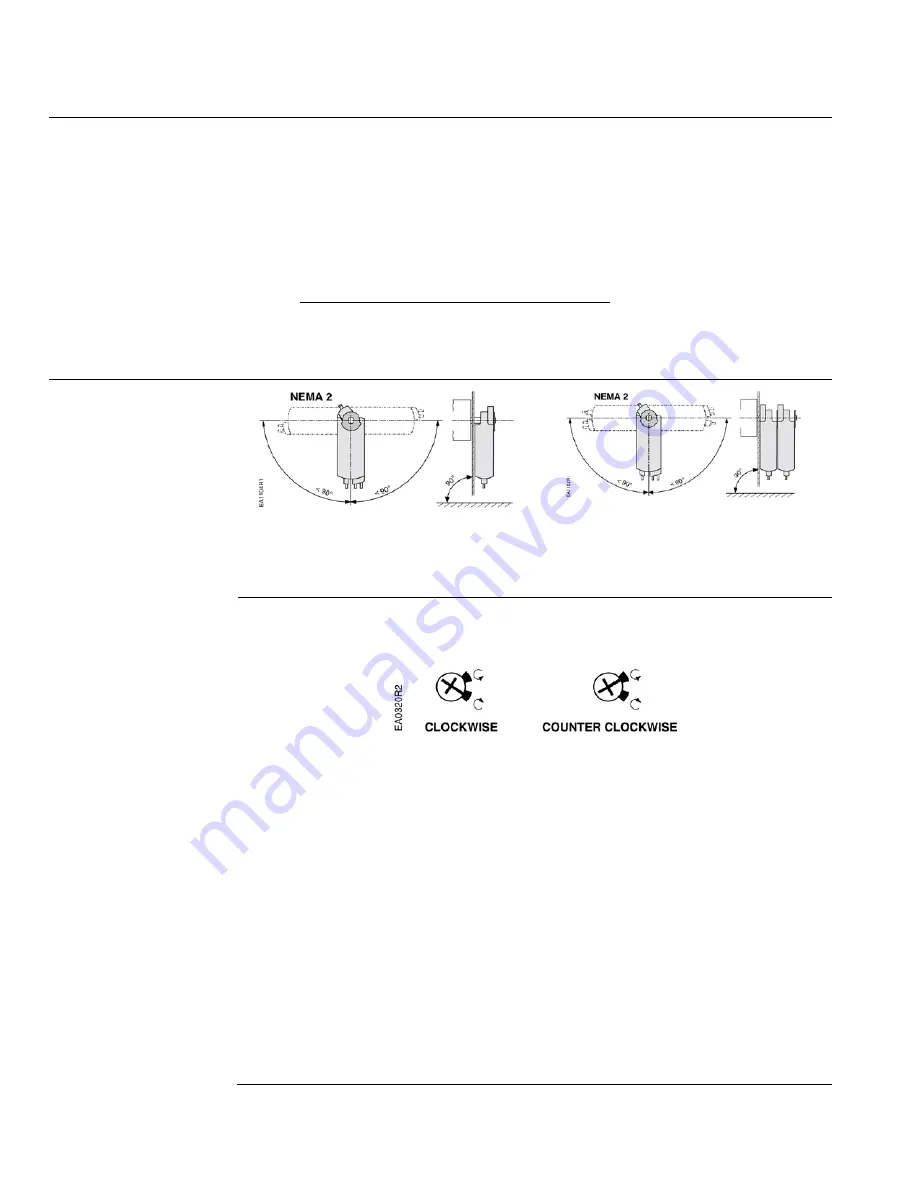

The direction of rotation switch must be set to match the clockwise or

counterclockwise rotation of the damper shaft. The factory setting is clockwise. See

Figure 14 for location on the actuator.

Figure 20. Direction of Rotation Switch.

•

The minimum damper drive shaft length is 3/4-inches (20 mm). The shaft length

determines whether the shaft adapter will be mounted on the front or back side of

the actuator.

•

See

Specifications

for minimum and maximum damper shaft dimensions.

•

The shaft adapter can be mounted on either side of the actuator. The direction of

rotation and shaft length determine how the shaft adapter will be mounted on the

actuator.

•

The position indicator can be mounted to show either the clockwise or

counterclockwise 0 to 90 scale.

•

The actuator is shipped from the factory with a 5° pre-load to ensure tight close off

of the damper.

•

The shaft adapter and mounting parts are shipped in a separate container with the

actuator.

•

Detailed mounting instructions are included with each actuator.