Installation Instructions

The following instructions are for the installation of a Siemens JD main breaker kit in a 400 amp Revised P1 Panel-

board. The parts provided in this kit are for connection to a 1-phase 2 or 3-wire system or to a 3-phase 3 or 4-wire

system. For all 1-phase systems, disregard the B-phase connector instructions. The breaker is NOT included with

this kit and must be purchased separately. Be sure to choose the appropriate breaker for the voltage, system &

feed location in use. For systems with no neutrals, disregard the neutral connection.

NOTE: Other main breaker kits may include this kit AND a breaker with main breaker support(s) attached.

White text on black background on these pages denote instructions specific to these particular kits (see

list on front cover). (For clarification, DANGER warning below applies to all.)

11-A-1115-01 Rev. 02

-3-

-2-

DANGER

Hazardous voltage.

Will cause death or

serious injury.

Keep out.

Qualified personnel only.

Disconnect and lock off all

power before working on

this equipment.

11. Attach the main cables to the breaker and neutral

terminal and torque connections to values specified

on the device. If no values are listed on the device,

refer to the Hardware Tightening Torque label

affixed to the rear of the deadfront.

8. On 1-phase 3-wire and 3-phase 4-wire systems,

neutral lugs are required. For the 600 kcmil neutral

lug (item 11), insert the 1/4”-20 x 1” carriage bolt

(item 13) through the square hole on the neutral

riser from below, then place the 600 kcmil neutral

lug and the anti-turn plate (item 12) as shown.

Finish with the 1/4”-20 belleville washer nut (item 14).

14. Before energizing the panel, ensure that all con-

nections have been properly torqued, that all

circuit breaker terminal covers are secured, that the

deadfront is installed and that all fillers are in place.

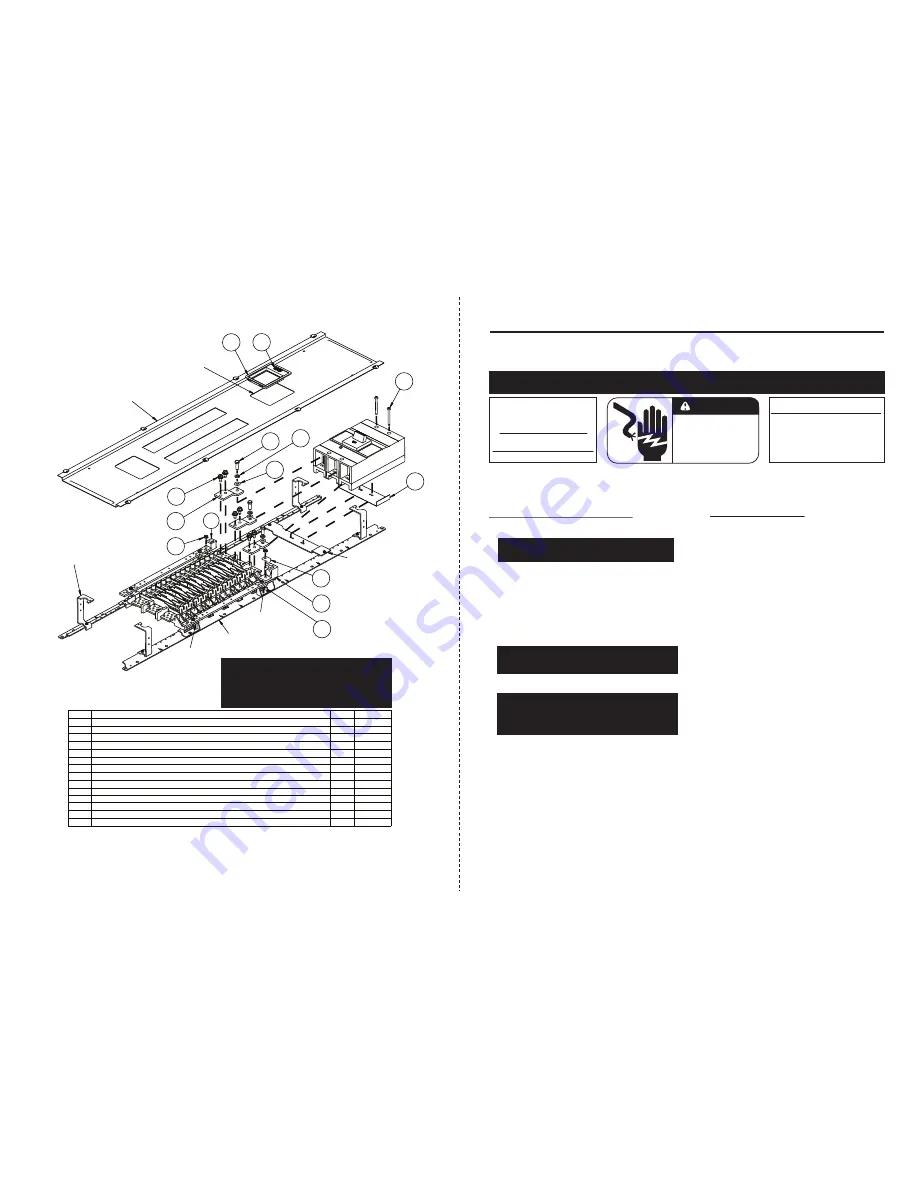

BREAKER SUPPORT BARRIER

1

PHASE CONNECTOR

BREAKER ESCUTCHEON

MAIN LABEL

3/8” NARROW WASHER

HELICAL SPRING LOCKWASHER

DEADFRONT

DEADFRONT

SUPPORT

BASE

RAIL

NEUTRAL

CROSS BUS

** (2) FOR 1Ø, (3) FOR 3Ø

NEUTRAL

CROSS BUS

**

**

**

1

1

MAIN

END

FEED-THRU

OR SUBFEED

END

1

2

3

4

5

6

7

3/8”-16 x 1” HEX HEAD BOLT

5/16”-18 x 3/4” HEX HEAD SEMS* ASSEMBLY SCREW

***

2

**

8

9

1/4”-20 x 2-3/4” PHILLIPS ROUND HEAD THREAD-FORMING SCREW

5. Position one of the outer breaker connectors

(item 2) so that the single-hole end rests on the

breaker pad and the double-hole end rests on

the panel section or main bus. Note that the

outer connectors are mirror images and are NOT

interchangeable. Attach the connector to the

breaker pad using 3/8”-16 bolt (item 7), a helical

spring lockwasher (item 6) and a plain washer

(item 5) as shown. Do not tighten at this time.

Repeat the process to attach the other outer

connector to the breaker.

6. 3-Phase panels require a B-phase connection.

Position the B-phase connector so that the single-

hole end rests on the breaker pad and the double-

hole end rests on the panel section or main bus.

Attach the connector to the breaker pad using

the same hardware as the A and C-phases.

Do NOT tighten at this time.

10. Torque all connections to the values specified on

the Hardware Tightening Torque label affixed to the

rear of the deadfront (or reference assembly instructions

where appropriate).

* SEMS ASSEMBLY SCREWS HAVE A CAPTIVE WASHER ON THE SCREW

THIS KIT CONTAINS THE FOLLOWING ITEMS:

ITEM

QTY

DESCRIPTION

4

9

MAIN

OPENING

3

2

BREAKER

SUPPORT

BRACKET

350 kcmil NEUTRAL LUG ASSEMBLY

600 kcmil NEUTRAL LUG

1

1

10

11

12

ANTI-TURN PLATE

1/4”-20 x 1” CARRIAGE BOLT

1

2

1

13

14

1/4”-20 BELLEVILLE WASHER NUT

*** (4) FOR 1Ø, (6) FOR 3Ø

1

5

6

7

8

11

10

14

12

13

4. Refer to Figure 2 on page 4 to determine the

correct breaker mounting for the panel’s feed

location. Also refer to main breaker instructions

for access to mounting holes; breaker covers

may need to be removed for access. Follow

instructions on the Wire Grip Kit Installation

Instructions to install breaker lugs (lug kit

TA2J6500; purchased separately) on the

correct end of the breaker before continuing.

TOP FEED:

Install lugs at the ON end of the breaker.

The breaker support bracket is pre-installed on

the breaker ON end. Attach this bracket to the

base rails using the hardware removed in step 3.

Skip to step 5.

BOTTOM FEED:

Install lugs at the OFF end of

the breaker.

Leave the pre-installed breaker support bracket

attached to the breaker but note it does not need

to be secured to the base rails. Instead, attach

the breaker to the existing mounted support

bracket (as shown in Fig. 2A on pg. 4) by

following these directions:

Insert both 1/4”-20 x 2-3/4” screws (item 9) through

the appropriate end of the breaker case and through

the outer holes on the support barrier (item 1)

as shown in Figure 1, to retain the barrier during

installation. Fasten the breaker to the support.

Figure 1

7. Fasten all breaker connectors to the panel section

or main bus using two 5/16”-18 SEMS screws

(item 8) per joint.

12. Remove the main lug blank filler from the deadfront

main opening (if present). Refer again to Figure 3

on page 4 to determine the correct orientation of the

deadfront main breaker escutcheon (item 3) for the

panel’s feed location. Insert the breaker escutcheon

into the front of the deadfront.

13. For main breaker applications, apply the “MAIN”

label (item 4) to the breaker escutcheon as shown.

For installation as a Main Breaker:

1. Lock off all power supplying this equipment

before working on it.

3. To install this kit for main breaker use, remove

the main lugs (if installed).

TOP FEED: Also remove the main breaker

support already installed onto rails. (Save

hardware for mounting of pre-installed support.)

2. Remove the deadfront.

9. Position the 350 kcmil neutral lug assembly (item 10)

under the neutral riser, allowing the stud to pene-

trate as shown. Fasten it to the riser with a 1/4”-20

belleville washer nut (item 14).

NOTE:

If the panelboard is fed by two 250 kcmil

or smaller cables, this lug assembly is used for the

second incoming cable and one of the 1/0 terminations

on the neutral strip is used for a grounding electrode

conductor (if required for service equipment appli-

cations). If the panelboard uses a 600 kcmil cable

for neutral and is being used as service equipment,

the 350 kcmil lug is used for the grounding electrode

conductor.

N/A

N/A

N/A

72 lb-in

TORQUE

N/A

N/A

N/A

72 lb-in

N/A

N/A

N/A

N/A

****

240 lb-in

**** TORQUE (lb-in): 72 for 1/8” CU; 108 for 3/16” or 1/4” AL; 144 for 3/16” CU

Bottom-feed mains are reverse fed,

and require Type JXD breakers.

Top-feed mains may be either

Type JD or JXD:

Top-feed Main Breakers:

JD, HJD, JXD, HJXD

Bottom-feed Main Breakers:

JXD, HJXD

The P1-400 Panel provides wiring

space for the following cable options:

For (2) 250 MCM line cables per

phase use breaker line lug

TA2J6500

or copper lug

TC2J6500

For (1) 600 MCM line cables per

phase use breaker line lug

TA1L6750

or copper lug

TC1J6600

NOTE: Kits that include a breaker will have the following

items pre-assembled to the breaker and are not included

in the itemized list on this page:

(1) Type JD circuit breaker

(1) breaker support barrier (see item 1)

(2) 1/4”-20 round head screws (see item 9)

(1) breaker support bracket

(All items in the itemized list below are included in this kit

for use as needed for installation per these instructions.)