DIAPHRAGM PUMP INFORMATION

WARNING:

ALWAYS wear protective

clothing, face shield, safety glasses and gloves

when working near or performing and

maintenance or replacement on your pump. See

MSDS Sheet from polymer supplier foe

additional precautions.

OUTPUT ADJUSTMENT CONTROLS

In most external controlled pumps the uppermost

knob serves as speed control. Graduations for

the Speed Knob appear directly on the face of the

control panel. The largest knob below is Stroke

Control.

1. Speed adjustment: Speed control provides

adjustment of the percent of maximum strokes

per minute. Turning this clockwise increase

stroke frequency.

Note AA7 Series Only:

When operating pump in the external mode, the

speed control knob should be fully turned counter

clockwise. A click indicates pump is in external

mode.

2. Stroke Adjustment; Stroke control

provides adjustment of percent of maximum

Liquifram (diaphragm) travel. Turning this knob

counterclockwise increases percent output per

stroke. Only adjust while pump is running.

PRIMING THE PUMP

Hold tip of syringe firmly in fitting with one

hand while using the other hand to pull back on

plunger. Repeat until a small amount of polymer

is drawn into the syringe. The pump is now

primed.

PUMP CALIBRATION

Perform calibration if your system application

requires it. Normally calibration is NOT required.

You will need:

- A watch

- A calculator

- Calibrated cylinder (with at least 1000 ml

capacity.

- Length of hose or tubing (same I.D. as

pump ports)

1. Maintain all usual connections to the

PolyBlend unit except disconnect the polymer

suction line at pump input. The flow meter and

pump setting should be those used for normal

service.

2. Connect hose or tubing to the pump input.

Place the free end of the tubing in the graduated

cylinder.

3. Fill the cylinder with polymer to its

measured capacity (for example, 1000 ml etc.).

4. Turn on the metering pump. Allow the

pump to run until all air has been exhausted from

the tubing and pump and polymer is injected into

the mixing chamber.

5. Stop the pump.

6. Refill the cylinder to the measured

capacity.

7. Start the pump again, and start timing as

the pump runs. For best results, let the pump run

long enough to pump at least half of the polymer

out of the graduated cylinder. (in general, the

longer the calibration period, the greater the

accuracy of the measurement).

8. Stop the pump. Record the time and level

of the polymer remaining in the cylinder. Fill in

the following equation to find the volume of

polymer pumped per one unit of time (a minute,

an hour, or a day).

Starting ml - Remaining ml = ml/Time

Calibration period

9. Compare the actual volume pumped to the

desired volume, and adjust pump controls.

10. Check volume again to confirm the new

settings.

11

Summary of Contents for PolyBlend PB200-2

Page 17: ...15 ...

Page 18: ...16 ...

Page 19: ...17 ...

Page 20: ...18 ...

Page 21: ...19 ...

Page 22: ...20 ...

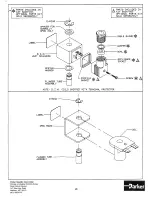

Page 24: ...200 D 007 ...

Page 26: ...MC 0101 24 ...

Page 28: ...Blank Page 26 ...

Page 30: ...OPD 0001 Post Dilution Static Mixer Assembly P N 5860001 28 ...

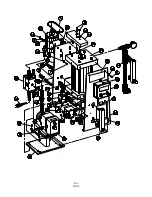

Page 32: ...Series AA7 Drive Assembly Exploded View Diagram 30 ...

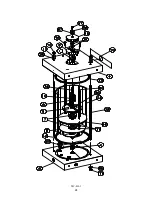

Page 35: ...33 ...

Page 36: ...34 ...