9/1/06

SIEMENS WATER TECHNOLOGIES CORP.

P.O. BOX 389

BRADLEY, IL 60915

TELEPHONE: 815-932-8154

800-882-6466

FACSIMILE: 815-932-0674

PolyBlend

®

Product Warranty

Siemens Water Technologies Corp. warrants

equipment of its manufacture and bearing its

trademark to be free of defects in material and

workmanship and to materially conform to any

applicable specifications and drawings approved

in writing by Siemens Water Technologies. If the

customer gives Siemens Water Technologies

Corp. prompt written notice of a breach of this

warranty within twelve (12) months from the date

of start-up by an authorized Siemens Water

Technologies Corp. technician or eighteen (18)

months from the date of shipment, whichever

occurs first (the “Warranty Period”), Siemens

Water Technologies Corp. will, at its sole option

and as the customer’s exclusive remedy, either

repair or replace free of charge, or refund the

purchase price paid with respect to, any material

found to be defective during the Warranty Period.

No repair or replacement of defective products

shall extend the Warranty Period, but any such

repaired or replaced product shall be covered by

the balance of the original Warranty Period. If

Siemens Water Technologies Corp. determines

that any claimed breach is not, in fact, covered by

this warranty, the customer shall pay Siemens

Water Technologies Corp.’s then customary

charges for any repair or replacement.

The foregoing warranty is conditioned upon the

customer’s (i) the customer shall have operated

and maintained the equipment in accordance

with all instructions provided by Siemens Water

Technologies Corp. (ii) the customer shall not

have made any unauthorized repairs or

alterations; (iii) the customer shall not be in

default of any payment obligation to Siemens

Water Technologies Corp. (iv) if requested, the

customer will deliver the equipment to a Siemens

Water Technologies Corp. authorized service

center and the customer shall pay all inbound

and outbound freight costs; (v) the customer

must provide a complete and detailed description

of the problem including, without limitation, the

Siemens Water Technologies Corp. job number,

date of delivery, date of installation, date of start-

up and the operating conditions of the unit(s); (vi)

return a duly completed Start-Up an Field Test

Report to Siemens Water Technologies Corp.

within thirty (30) days of start-up; and (vii) for

equipment which is destined for extended

storage, such equipment must have been stored

in accordance with the Storage Requirements

detailed in the operation and maintenance

manual (storage of equipment does not extend

the Warranty Period).

The foregoing warranty does not extend to, and

Siemens Water Technologies Corp. assumes no

responsibility for, (i) the installation quality or any

service defects resulting therefrom unless a

Siemens Water Technologies Corp.

representative or designee supervised the

installation; (ii) in the event that the unit size and

location are predetermined by someone other

than Siemens Water Technologies Corp. or our

local representative, the serviceability and/or

performance of the unit for the specified design

and/or actual operating conditions (this exclusion

shall not apply if all necessary design information

is submitted to and approved in writing by

Siemens Water Technologies Corp.); (iii) any

auxiliary equipment or accessories supplied by

Siemens Water Technologies Corp. but

manufactured by others (the original

manufacturer's warranty, if any, shall apply to

such products); (iv) damage to the equipment or

products resulting from normal wear, abuse,

neglect or operation in a manner inconsistent

with Siemens Water Technologies’

recommendations; and (v) damage to equipment

or products that have been modified, tampered

with or altered without written consent from

Siemens Water Technologies.

In addition to the foregoing conditions and

limitations, the following product-specific

limitations and conditions must be satisfied for

the foregoing warranty to apply:

1. This warranty does not cover damage

caused by chemical action or abrasive

material (including, without limitation,

particulates in the makeup water), damage

caused by handling or during transportation,

or damage arising from misuse, installation

or any other cause beyond Siemens Water

Technologies’ control. Standard units not in

outdoor configurations are not warranted in

outdoor applications.

2. If a non-potable water source is used as

primary or secondary dilution water to the

PolyBlend® unit, the warranty period shall

not exceed ninety (90) days from the date of

shipment.

HydroForce

®

Product Warranty

The HydroForce® mixing assembly, part of the

PolyBlend® product line, is covered for the life of

the product by the limited warranty set forth

herein, provided that the limited lifetime warranty

extends only to the original user of the product.

5

Summary of Contents for PolyBlend PB200-2

Page 17: ...15 ...

Page 18: ...16 ...

Page 19: ...17 ...

Page 20: ...18 ...

Page 21: ...19 ...

Page 22: ...20 ...

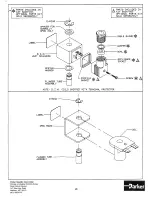

Page 24: ...200 D 007 ...

Page 26: ...MC 0101 24 ...

Page 28: ...Blank Page 26 ...

Page 30: ...OPD 0001 Post Dilution Static Mixer Assembly P N 5860001 28 ...

Page 32: ...Series AA7 Drive Assembly Exploded View Diagram 30 ...

Page 35: ...33 ...

Page 36: ...34 ...