Siemens ProtoAir Start-up Guide

Page 34 of 66

Appendix A.5 Taking a FieldServer Diagnostic Capture

When there is a problem on-site that cannot easily be resolved, perform a diagnostic capture before

contacting support so that support can quickly solve the problem. There are two methods for taking

diagnostic captures:

•

FieldServer Toolbox:

This method requires installation of the FS Toolbox program. A FS Toolbox diagnostic capture

takes a snapshot of the loaded configuration files and a log of all the communications on the

serial ports over a specified period of time. If the problem occurs over an Ethernet connection,

then take a Wire Shark capture.

•

G

ateway’s FS-GUI Page:

This method doesn

’t require downloading software. The diagnostic capture utilities are embedded

in the FS-GUI web interface. Starting a diagnostic capture takes a snapshot of the loaded

configuration files and a log of all the communications over a specified period of time. This works

for both serial and Ethernet connections.

NOTE: The information in the zipped files contains everything support needs to quickly resolve

problems that occur on-site.

Appendix A.5.1 Using the FieldServer Toolbox

Once the Diagnostic Capture is complete, email it to technical support. The Diagnostic Capture will

accelerate diagnosis of the problem.

•

Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the

FieldServer-Toolbox.zip via the Sierra Monitor

•

Extract the executable file and complete the installation.

•

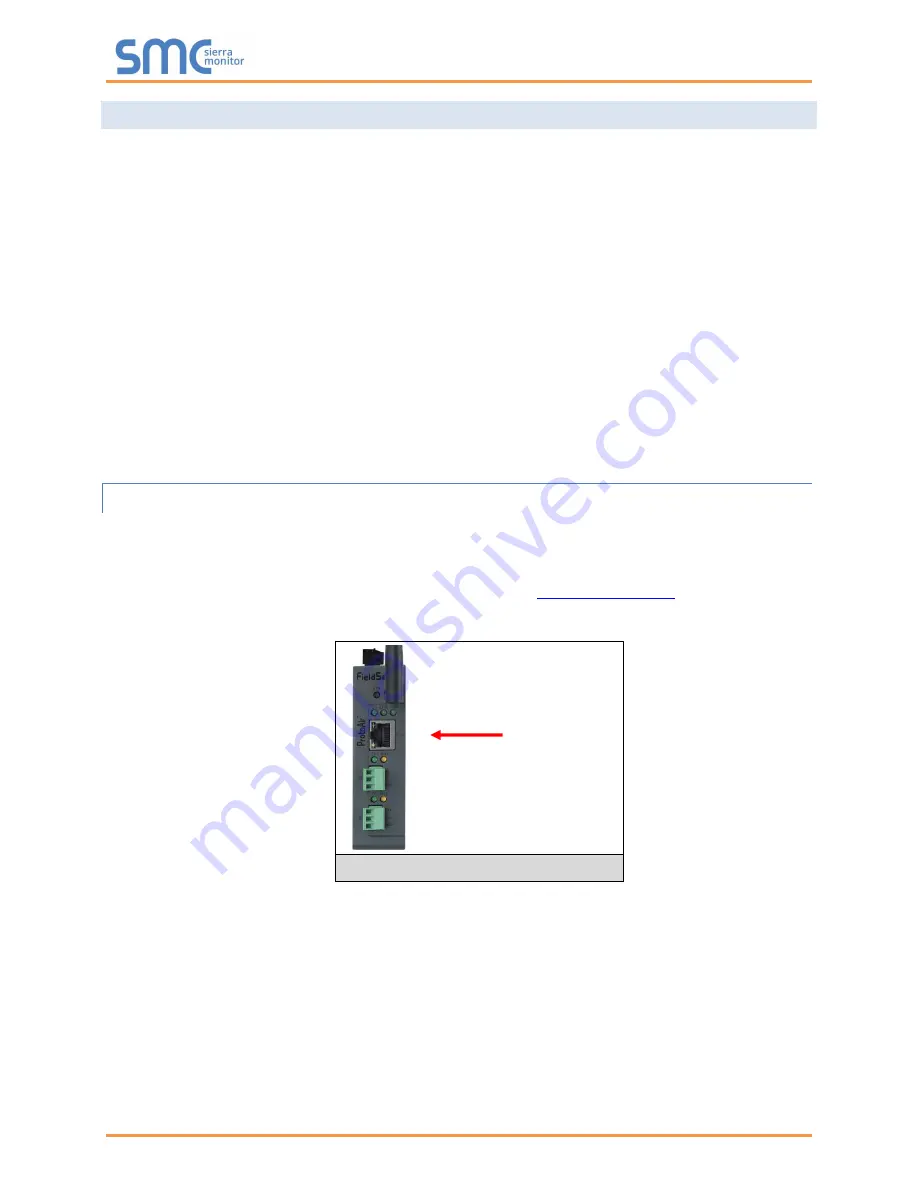

Connect a standard Cat-5 Ethernet cable between the PC and ProtoAir.

•

Double click on the FS Toolbox Utility.

Ethernet Port

Figure 27: Ethernet Port Location