Summary of Contents for RAJA+ 3TE7111-2BC21-1A Series

Page 1: ...Installation Maintenance Troubleshooting Guide For RAJA Agriculture Starters Controllers ...

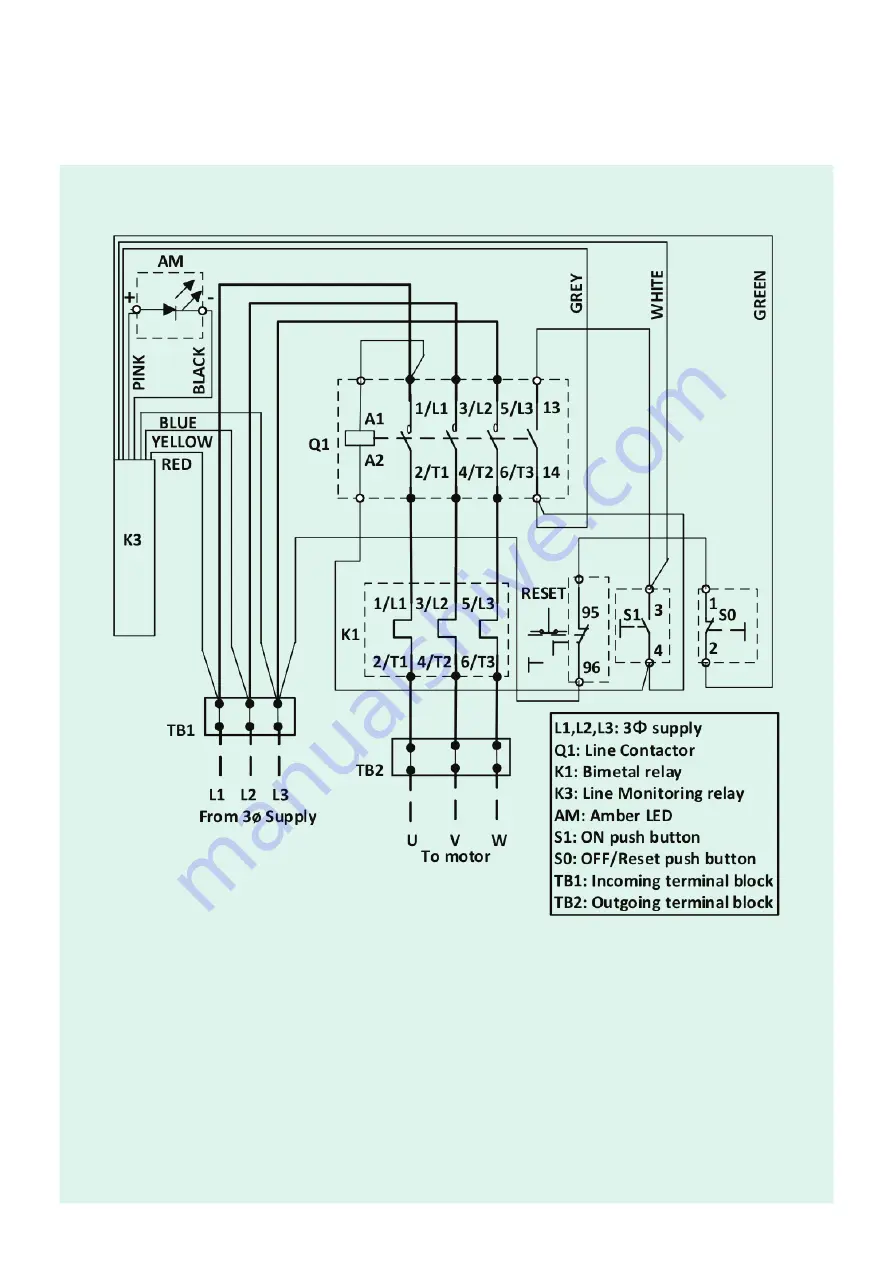

Page 5: ...1 2 Wiring Diagram Installation Maintenance Troubleshooting guide Version 01 5 ...

Page 6: ...6 Control logic diagram Installation Maintenance Troubleshooting guide Version 01 ...

Page 7: ...7 Power circuit diagram Installation Maintenance Troubleshooting guide Version 01 ...