Article no. SI EP CC RajaSM5 042021

Published by

Siemens Ltd

Smart Infrastructure

Electrical Products

R&D Building, 48,

Thane-Belapur Road

Thane 400708, India

Smart Infrastructure intelligently connects energy systems,

buildings and industries, enhancing the way we live and

work to significantly improve efficiency and sustainability.

We work together with customers and partners to create

an ecosystem that both intuitively responds to the needs of

people and helps customers achieve their business goals.

It helps our customers to thrive, communities to progress

and supports sustainable development to protect our planet

for the next generation.

Creating environments that care.

siemens.com/smart-infrastructure

Subject to changes and errors. The information given in this document only contains

general descriptions and/or performance features which may not always specifically

reflect those described, or which may undergo modification in the course of further

development of the products. The requested performance features are binding only

when they are expressly agreed upon in the concluded contract.

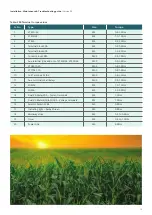

Summary of Contents for Raja+ 3TE7431- 2CC25-1A Series

Page 1: ...Installation Maintenance Troubleshooting Guide For RAJA Agriculture Starters Controllers ...

Page 6: ...5 21 Control logic diagram 6 Installation Maintenance Troubleshooting guide Version 05 ...

Page 7: ...Installation Maintenance Troubleshooting guide Version 05 5 22 Power circuit diagram 7 ...