7/8

Siemens Building Technologies

Room temperature controller REV100

CE1N2211en

Landis & Staefa Division

16.05.2000

•

When installing the controller, the base must first be fitted and wired. Then, the unit

can be engaged at the top, swung downward and snapped on

•

For more detailed information, refer to the installation instructions supplied with the

unit

•

For the electrical installation, the local safety regulations and standards must be

complied with

•

The remote control contact T1/

T2 must be wired separately, using a shielded cable

•

The battery transit tab, which prevents inadvertent operation of the unit during trans-

port and storage, must be removed

•

The control characteristic can be changed with the DIP switch located at the rear of

the unit

•

If the reference room is equipped with thermostatic radiator valves, they must be set

to the fully open position

•

If the room temperature displayed does not agree with the measured temperature,

the sensor should be re-calibrated (refer to section "Calibration of sensor").

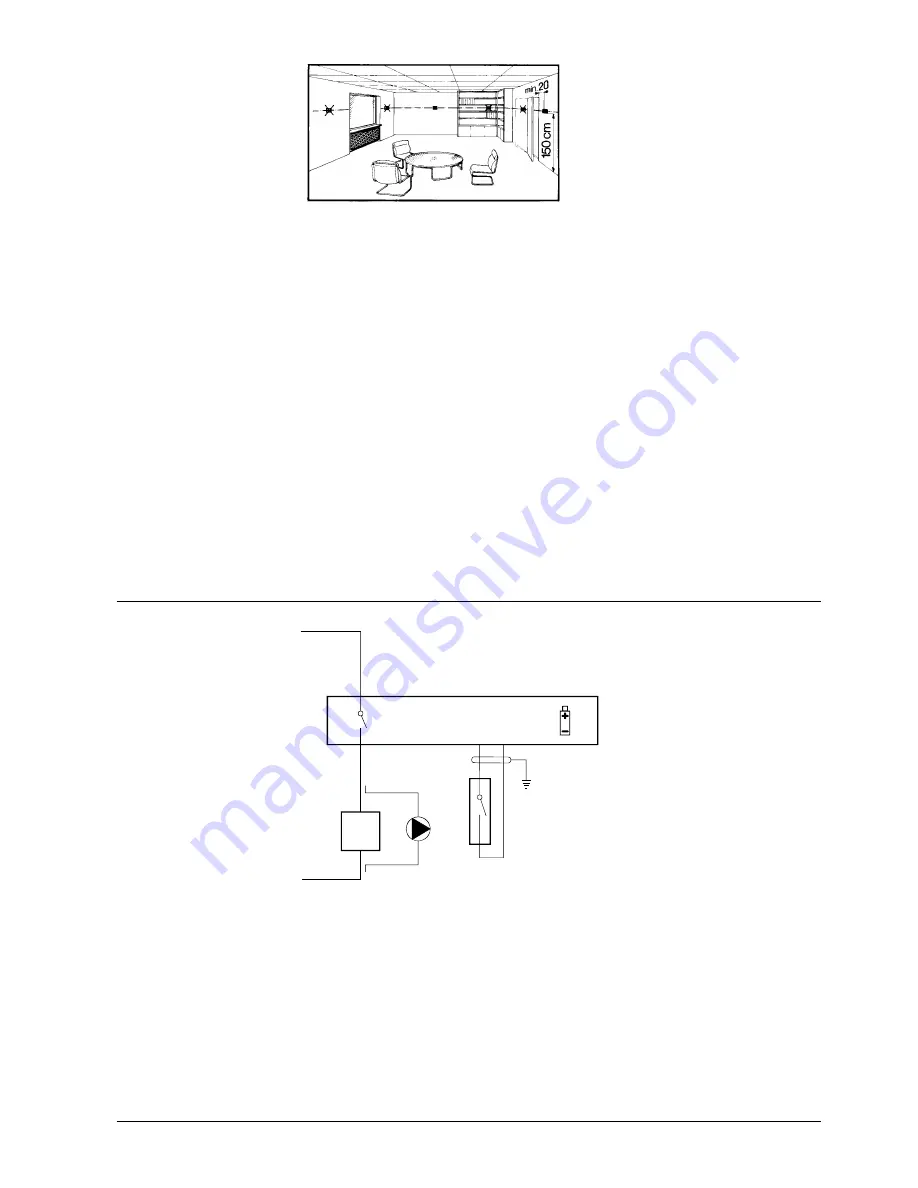

&RQQHFWLRQGLDJUDP

L

L1

Y1

M1

N1

N

S1

T1 T2

2

211A

01

A

C

2

4

..

.2

5

0

V

DC

3

V

L

Live, AC 24 ... 250 V

S1

Remote operating unit (potential-free)

L1

N.O. contact, AC 24 ... 250 V / 8 (3.5) A

T1

Remote control signal

M1

Circulating pump

T2

Remote control signal

N1

REV100 controller

Y1

Regulating unit

0RXQWLQJDQG

LQVWDOODWLRQ

&RPPLVVLRQLQJ