Operation

De

sc

ri

p

ti

o

n

The continuous current and interrupting ratings of the circuit

breakers are as shown on the circuit breaker rating labeL

The circuit breakers are also available with integrally mounted

current limiting fuses through

2000A

frame size, and with

separately mounted fuses for

3200A

and

4000A

frame size.

For

800A, 1 600A.

and

2000A

frame sizes the basic circuit

breakers are the same with or without fuses. The fuses mount

on a bracket that is bolted to the side plates and upper studs

on the back of the circuit breaker. Due to this difference. fused

circuit breakers are not interchangeable with unfused circuit

breakers. The current limiting fuses i ncrease the interruption

rating to that of the fuses. Fused circuit breakers are identified

as

RLF-800, RLF-1600, RLF-2000. RLF-3200,

or

RLF-4000.

Fused circuit breakers are also equipped with an open fuse

trip device to open the circuit breaker if one or more current

limiting fuses open.

Note:

Fused circuit breakers are not physically interchange

able with unfused breakers.

Unfused circuit breakers can also be supplied for stationary

mounting in which the rackin g components are omitted and

brackets are provided for mounting to a stationary frame.

A l l

RL

c i rcuit b reakers u s e the same basic c l o s i n g

mechanism o r operator. The closing springs used vary be

tween sizes.

Two configurations of the operator are available for charging

the clos i n g s prings, manually charged or electrically

charged. F

o

r electrical operators. a maintenance handle

accessory can be used to charge the springs manually for

maintenance or i n an emergency. Optionally, a built-in

manual spring charging handle can be provided.

The manual and electrical operators are identical except for

the means of supplying energy to the closing springs. A

double-togg le, trip-free mechanism is used. This means that

the breaker contacts are free to o pen at any time if required.

regardless of the position of the mechanism.

Precautions to

be

Observed

in

Operation

1 .

Read

this

Instruction

Guide before i

ns

t

a

l

l

i

n

g or

making

any changes or adjustments on the circuit breaker.

2. Stored-energy closing springs may be charged with cir

cuit breaker contacts in either the open or closed posi

tion. Extreme care should be taken to discharge the

springs before working on the circuit breaker.

3.

When closing manually operated breakers out of the com

partment. the racking mechanism must be returned to the

test position before the closing spring can be charged.

4.

vVhen charging manually operated breakers. always hold

the handle firmly until it is returned to the normal vertical

position. A ratchet insures that the closing stroke must be

completed once started.

5. Check current ratings. circuit breaker wiring information,

circuit breaker type and trip device type, against the

One-Line Diagram to assure that circuit breakers are

l ocated i n t h e p ro p e r c o m p a rtments w i t h i n the

sv:itchgear.

6.

Check the alignment of the secondary

disconnect

fingers.

6

This

ensures against misalig nment due to possible distor

tio:� of finger

s

du ring

the

s

hipme

n

t an

d

ha

n

d

li

n g

.

7. Close the compartment door and secure door latch(s)

prior to racking the circuit breaker to or from the CON

NECTED position. Also close and latch the door prior to

closing the circuit breaker when i n the CONNECTED

position. Once the circuit breaker is closed, keep the door

closed.

8.

Once the circuit breaker is energized, it should not be

touched, except for the exterior controls.

Manually Operated Breakers

The breaker has a center-mounted frame so many of the

latches and links are arranged in pairs. For descriptive pur

poses. they will be referred to as single items.

Refer

to

Figure

2

and

Table 1 .

Detail (A) shows the position of the trip

latch and toggle linkage when the circuit breaker is open and

the closing springs are discharged.

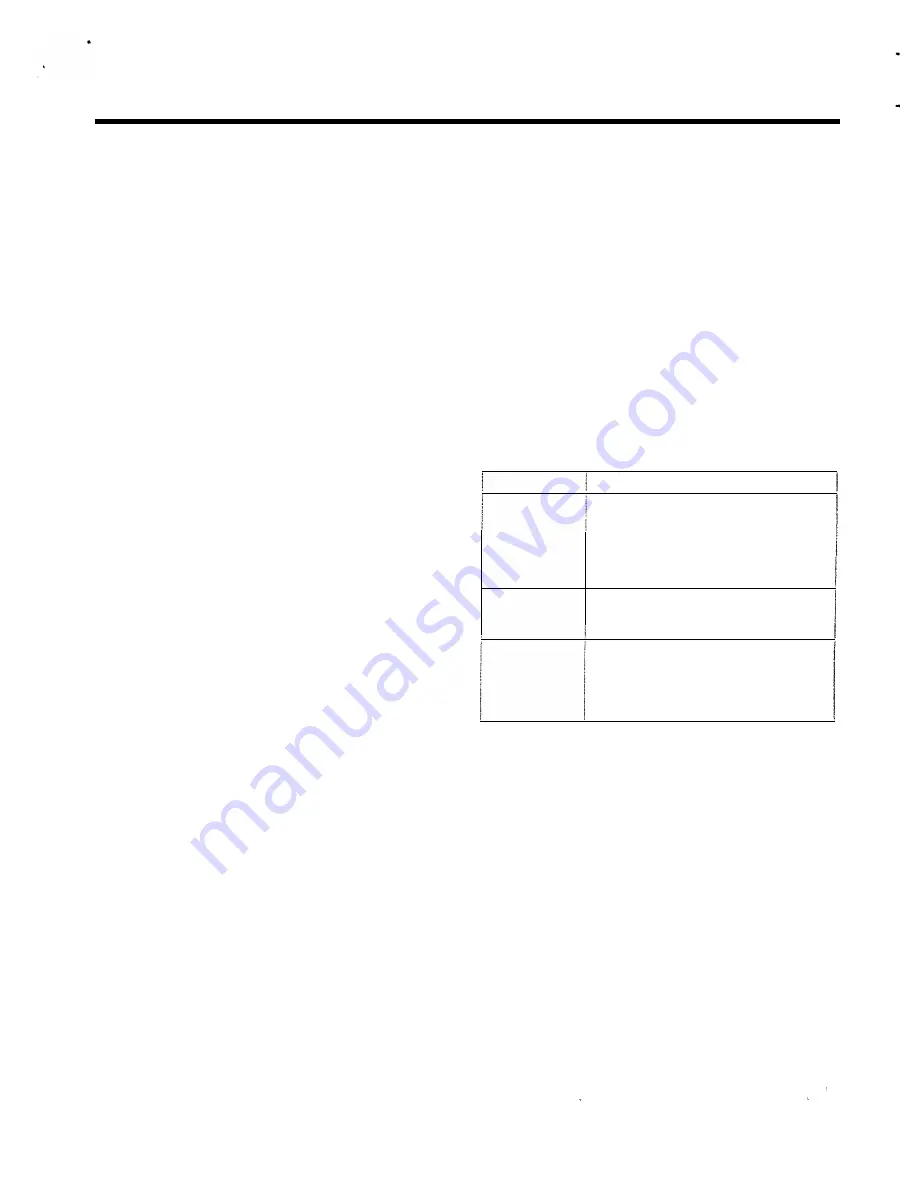

Table 1 .

Operatin g Procedure Manually Operated Circuit Breakers

Operation

Charging

Springs

Closing

Tripping

Procedure

Pull charging handle down all the

way (approximately

1 20•)

and return

it to normal vertical position.

(Engagement of pawl with ratchet

teeth prevents handle reversal until

the downward stroke is completed.)

Push down firmly on spring-release

latch hood

(50)

after handle is

returned to normal vertical position.

Push in manual trip rod

(94).

OR

If

shunt trip is provided, operate

remote trip control switch (CST). (See

Figure

3.)

Movement of the charging handle downward rotates closing

ratchet

( 1 40)

against roller

(43).

thus pivotin g dosing cam

(34)

clockwise about pin

(40).

This extends the closing

springs through link (4 1 ) and spring hanger (58). Rotation of

cam

(34)

allows roller (27) in toggle linkage to be moved into

position shown in Detail

(B).

Kickoff spring ( 1 0) moves rollers

away from the sh?P block (7). Then the toggle linkage is

moved by torsion spring until latch ( 1 5) clears trip flap (1 2).

Spring

( 1 3)

causes trip flap

( 1 2)

to reset u nder l atch ( 1 5). Trip

flap

(

1 2)

should normally stop against the front surface of

latch ( 1 5).

When the closing springs are fully charged, roller

( 43)

engages latch (47). Closing ratchet

( 1 40)

engages a pawl

in

such a manner that the charging cam must complete the

charging stroke before it can return to its normal position.

With the charging handle in its normal upright position. the

circuit breaker can be closed. By pressing firmly on hood

(50). latch ( 47) will disengage roller

(

43).

Then closing springs

cause closing cam

(34)

to rotate against the toggie rollers

(27). moving the toggle into

its

upright p

o

si

t

i

o

n

,

as shown in

detail (C). The cl

o

si

n

g cycle can be i nterr

u

pte

d

at

any point

by

opera:ion

of one

of

the tripping means. This will cause

rotation

of

trip flao ( 1 2)

to

a

positio:�

that releases la:ch 1 1 5; .

allov

'.

ing. togg ie linkage t o collapse t o :he position

shown i:�

de:a11

<A;.

www

. ElectricalPartManuals

. com