Siemens Building Technologies

CE1G3334xx

2017-11-01

3/21

Fehlersuche

Falsches Ergebnis

Mögliche Ursachen

Ventil reagiert nicht

·

Nicht angeschlossen

·

Keine Betriebsspannung

Ventil läuft auf statt zu

oder

Ventil läuft zu statt auf

·

Wirksinn falsch eingestellt

·

Falsche Reglerklemme

verdrahtet

Ventil bleibt in einer

Endlage stehen

Temperatur-Einstellschieber

steht auf EXT und es ist kein

Fernsollwertgeber ange-

schlossen

Regelung reagiert zu

langsam

·

P-Band tiefer einstellen

·

Bei PI zusätzlich kürzere

Nachstellzeit wählen

Regelung ist instabil

·

P-Band höher einstellen

·

Bei PI zusätzlich längere

Nachstellzeit wählen

en

English

Installation

Place of installation

Maximum permissible ambient temperature = 50 °C

·

Flow temperature control:

-

In the heating flow; immediately downstream from

the pump if pump is installed in the flow

-

In the heating flow approximately 1.5...2 m down-

stream from the mixing point if pump is installed in

the return

·

Return temperature control:

1...1.5 m downstream from the mixing point

·

Minimum limitation of the boiler return temperature and

maximum limitation of the flow temperature:

1...1.5 m downstream from the mixing point

·

D.h.w. temperature control:

1.5...2 m downstream from the mixing point

·

Heat exchanger control:

As close as possible to the heat exchanger

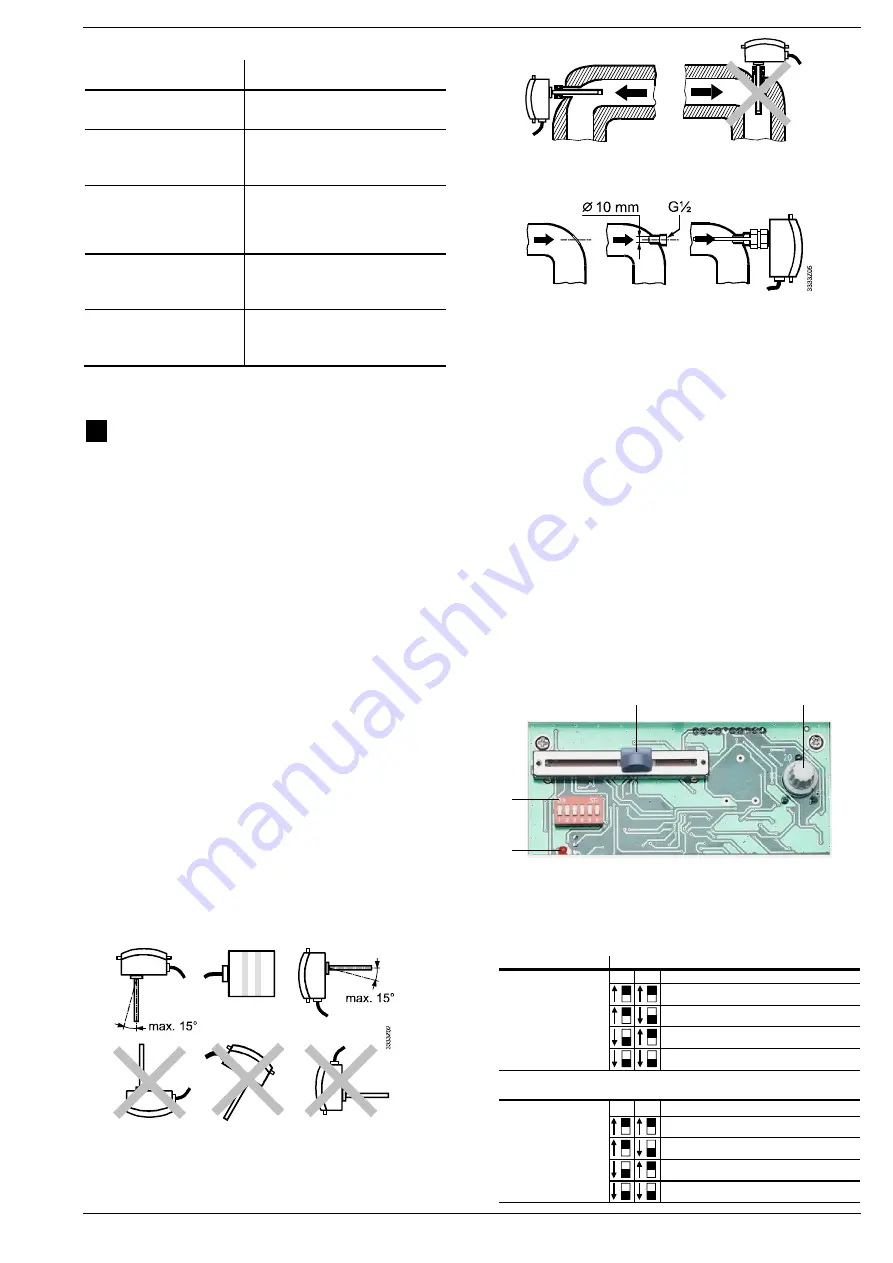

Mounting

The immersion temperature controller is designed for use

with protection pocket:

Procedure:

1. Drain the piping system.

2. Choose one of the following mounting positions:

The controller may not be mounted upside down and the cable may not

enter from the top.

The minimum immersion length must be 60 mm.

33

3

3Z

04

The controller should be mounted in a pipe bend with the protection

pocket facing the flow.

3. Use threaded nipple:

4. Fit protection pocket in the pipe. If required, use

sealing material (hemp, Teflon tape, or similar).

5. Insert controller into the protection pocket and snap it

on.

6. Fill piping system again.

Electrical Installation

·

Ensure that the local regulations for electrical installa-

tions are complied with

·

The connecting terminals are located under the flexible

plastic cover

·

Make wiring according to the plant documentation. If

not available, use the connection diagrams contained in

these Installation Instructions

·

Observe the permissible cable lengths

·

Switch on power only when commissioning the control-

ler

·

External preliminary protection with max. C 10 A circuit

breaker is required in all cases

Settings

3

3

3

4

P

0

1

1

2

3

4

1 LED for test mode / normal operation

2 DIP switch block

3 Setting slider for setpoint increase or decrease

4 Potentiometer for P-band Y1

Operating mode:

Where?

What?

DIP switch block,

switches no. 1 and 2

1

2

Heating with boost (setpoint increase)

Maximum limitation

Minimum limitation

Heating with ECO (setpoint decrease)

Control mode and integral action time:

DIP switch block,

switches no. 3 and 4

3

4

300 s (VERY SLOW)

180 s (SLOW)

60 s (FAST)

120 s (MEDIUM)