Internal Accessories

Electric Motor Op erator

.

.

.

,.

,

. ..

,'

�·

.. ..

..

...

. · ·

.. ..

.. ..

11

-

1 2 initial adjustment clearance

1

While holding actuator against switch

\

body. Adjust switch to obtain 11 - 1 2

clearance. Breaker springs must be

discharged and main contacts open.

\

Adjust

�

Switch

7.) Adjust the switch while holding the Actuator against the

switch body. Adjust the switch so that there is .11 -.1 2 inch

clearance between the switch Actuator and the Latch Lever.

Tighten screws to 9-1 1 in. lbs. Check adjustment after

tightening screws and readjust if necessary.

40

Slot

Latch

Tab

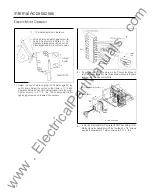

8.) Plug L T6 and L T7 Connectors into the Connector Strip until

latch tabs snap into slots. Gently pull wires to ensure they are

latched into the Connector Strip.

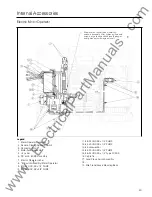

Motor Operator Assembly

#6-32

X

1/4"

#6

Lockwasher

�/

E C M C

Assembly

9.) Install the Electric Motor Controller (ECMC Assembly) to the

Motor Operator Assembly with the four #6-32

x

1/4" screws

and #6 lockwwashers. Torque screws to 9-1 1 in.-lbs.

www

. ElectricalPartManuals

. com