46

Internal Accessories

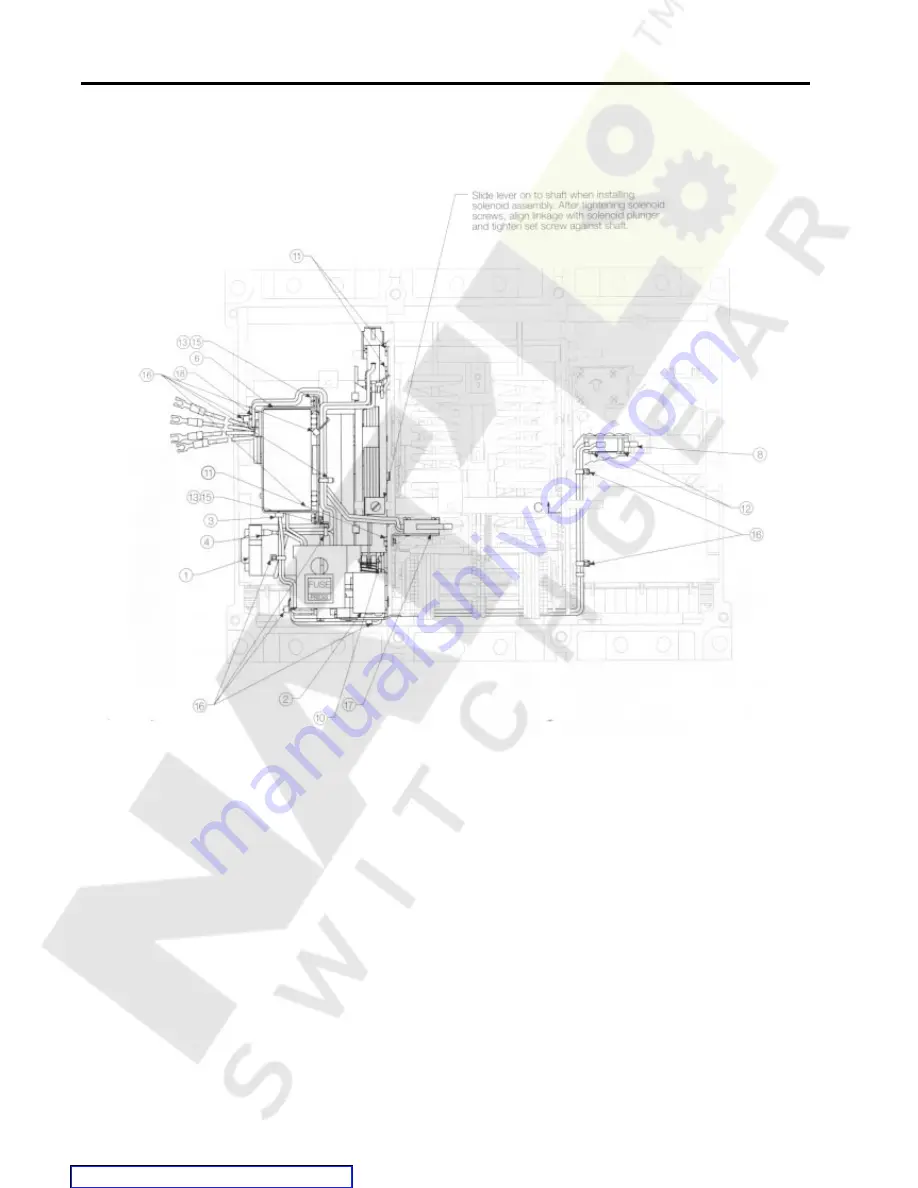

Electric Motor Operator

Legend

1. Motor Operator Assembly

2. Remote Closing Solenoid Switch

3. Connector Strip

4. Motor Fuse Connector

5. UL Label

6. DC or AC ECMC Assembly

7. Electric Operator Label

8. “B” Switch Assembly (Motor Operator)

9. #10-32 UNC-2B x 1/4" PHMS

10. #10-32 UNC-2B x 3/8" PHMS

11. #6-32 UNC-2B x 1/4' PHMS

12. #4-40 UNC-2B x 1/2" PHMS

13. #6 Lockwasher

14. #6-32 UNC-2B x 1/4" PHMS

15. #6-32 UNC-2B x 1/4" Type F CPHS

16. Cable Tie

17. Local Close Switch Assembly

18. Wire Tie Adhesive Mounting Base

Summary of Contents for SBA 1200

Page 68: ...66 External Accessories Ground Fault Sensing and Relaying Courtesy of NationalSwitchgear com ...

Page 94: ...92 Outline Dimension Drawing 2000A Fixed Mounted Courtesy of NationalSwitchgear com ...

Page 95: ...93 Outline Dimension Drawing 2000A Fixed Mounted Courtesy of NationalSwitchgear com ...

Page 100: ...98 Courtesy of NationalSwitchgear com ...

Page 101: ...Electrical Diagrams 99 Courtesy of NationalSwitchgear com ...

Page 102: ...100 Electrical Diagrams Courtesy of NationalSwitchgear com ...