Maintenance

Figure 22.

Side View SDV, Typical.

Checks of the Stored Energy Operator Mechanism

The stored energy operator checks are divided into me-

chanical and electrical checks for simplicity and better or-

ganization. The first series of checks determine if the basic

mechanism is clean, lubricated and operates smoothly with-

out control power. The contact erosion check of the vacuum

interrupter is also performed during these tasks.

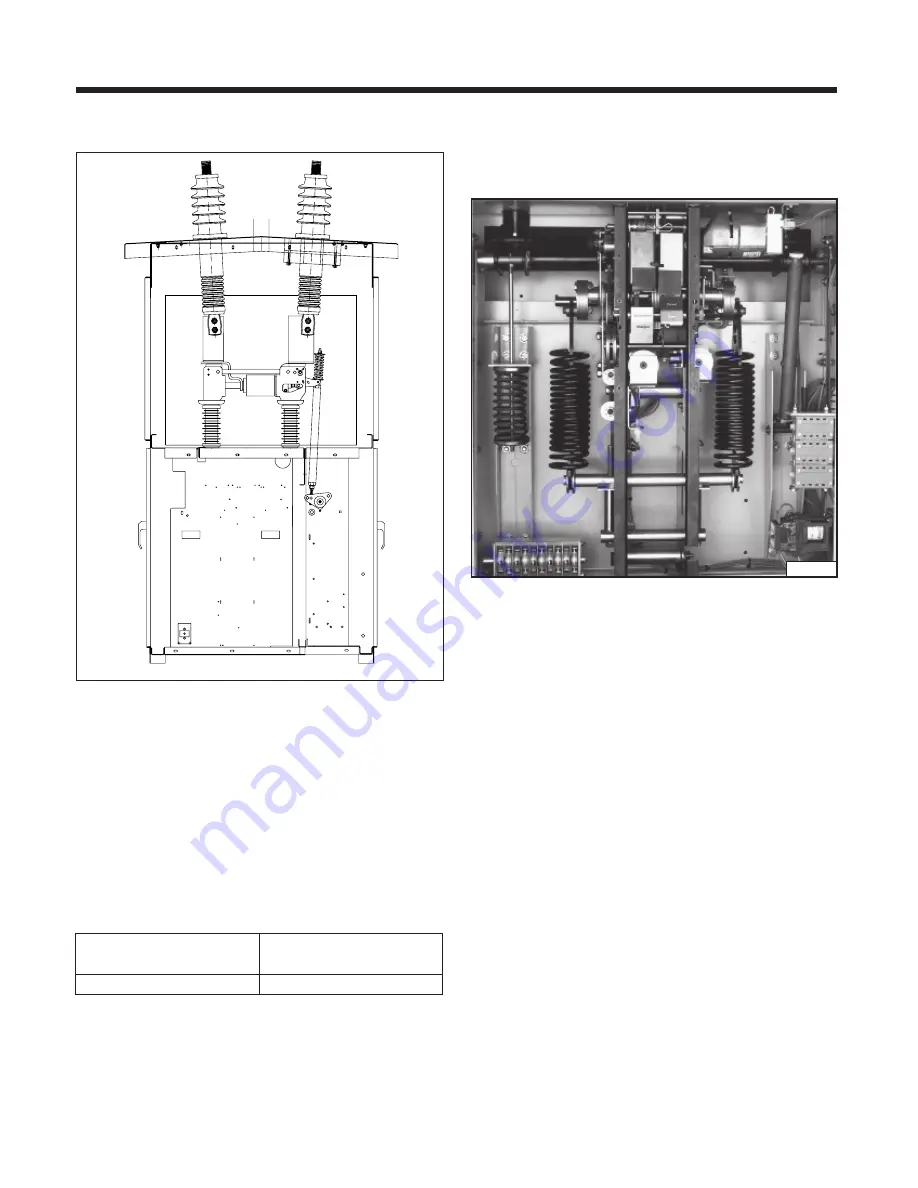

The interrupter operator mechanism is shown in Figure 23

with the access door open and the operator control panel

removed to show construction details. Both the tripping

spring and the two closing springs are shown. The mov-

able end of each closing spring is connected to a crank

arm. The movable end of the opening spring is connected

to the jack shaft by a pull rod. The dashpot is connected to

the jack shaft operating shaft by a pushrod linkage.

Figure 23.

Front View of Operator Mechanism.

Clean the entire stored energy operator mechanism with a

dry lint-free cloth.

Check all components for evidence of excessive wear. Place

special attention upon the closing spring cranks and the

various pushrods and linkages.

Lubricate all non-electrical moving or sliding surfaces with

a light coat of synthetic grease or oil. Lubricants composed

of diester oils and lithium thickeners will be compatible.

Shell (drawn cup) needle bearings: Use either Beacon

(Exxon) 325 (reference 18-658-676-422 and part number 15-

337-131-001), or Supermil (Amoco) A-72832 (reference 18-

658-676-423), or Anderol 732 aerosol synthetic fluid grease

(reference part number 15-172-816-058).

Pivots, sliding, and/or rolling surfaces and general lubrica-

tion: Use Anderol 732 aerosol synthetic fluid grease (refer-

ence part number 15-172-816-058).

Fastener Check - Inspect all fasteners for tightness. Lock-

nuts, retaining rings and X-washers are used. Replace any

fasteners that appear to have been frequently removed and

replaced. X-washers can not be reused and must be re-

placed any time they are removed

Manual Spring Charging And Contact Erosion Checks -

Perform the Manual Spring Charging Check contained in

the section describing the Installation Check and Initial Func-

tion Tests. The key steps of this procedure are repeated

here.

Number of

Years/Closing Operations

1

Five year interval for SDV breakers manufactured January, 1992 or later.

One year interval for units manufactured earlier.

Maintenance and Lubrication

Table 3: Maintenance and Lubrication Intervals

ANSI C37.06 Table 7 - Usual Service Conditions

Maintenance Based Upon Number of Breaker Closing

Operations

Breaker Type

SDV

5 years

1

/500 operations

2100-98

23