33

Instruction manual

| Types SDV-R and SDV-R-AR distribution circuit breakers

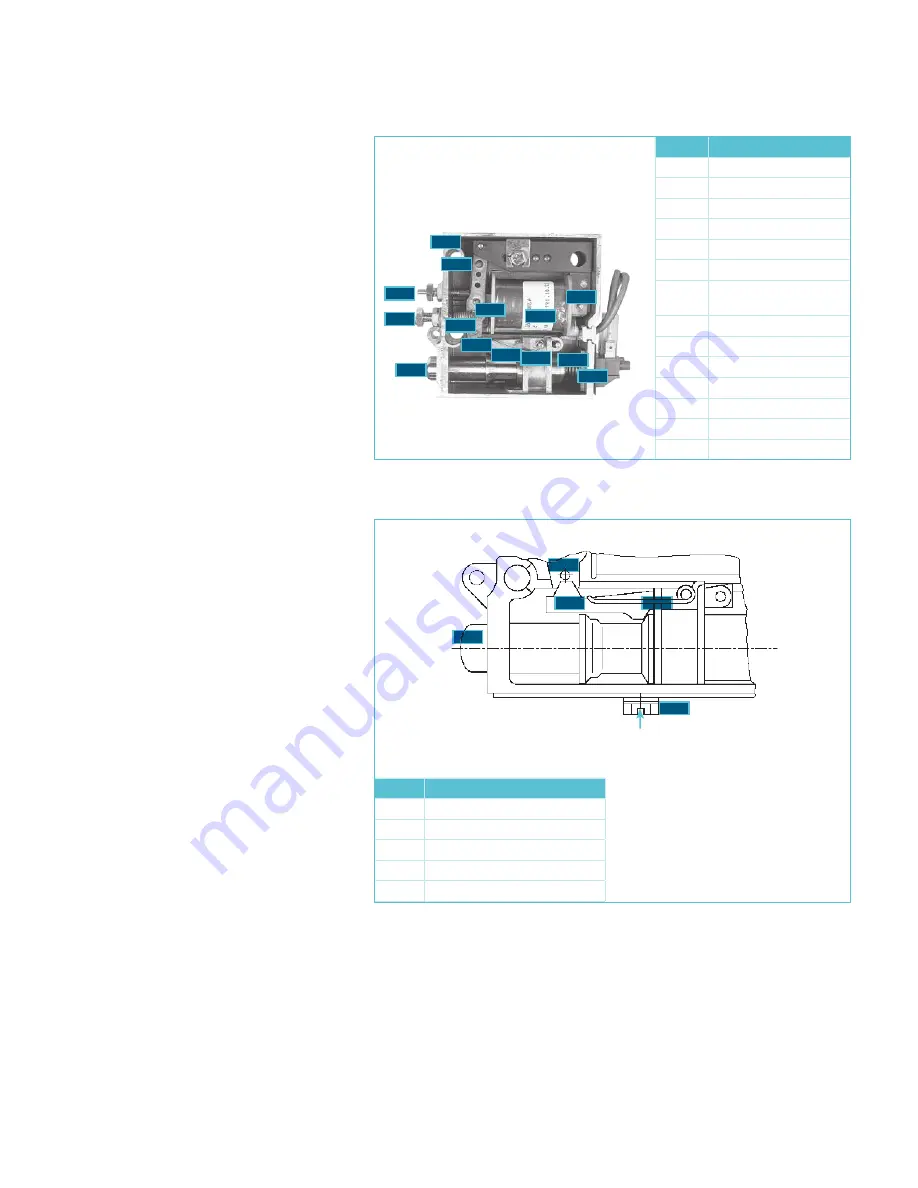

Item

Description

1.0

Magnet core

3.0

Housing

5.0

Mounting holes

7.0

Magnet coil

9.0

Magnet armature

11.0

Tension spring

13.0

Adjusting screw

(factory set) for 11.0

15.0

Tripping pin

21.0

Locking pin

23.0

Striker pin

25.0

Latch

27.0

Spring

31.0

Striker-pin spring

33.0

Terminal block

Item

Description

21.0

Locking pin

23.0

Striker pin

25.0

Latch

27.0

Spring

29.0

Locked/unlocked selection screw

Indirect releases - secondary shunt

release (auxiliary trip) (52T1) or

undervoltage

The indirect release provides for the

conversion of modest control signals into

powerful mechanical-energy impulses. It is

primarily used to open medium-voltage

circuit breakers while functioning as a

secondary shunt-release (dual trip) or

undervoltage device.

These releases are mechanical energy-

storage devices. Their internal springs are

charged as a consequence of the circuit

breaker mechanism operation. This energy

is released upon application or removal (as

appropriate) of applicable control voltages

(refer to Figure 19: Construction of

secondary shunt release (shown charged),

Figure 20: Latch details (shown charged)

and Figure 21: Undervoltage lock/operate

selection on page 34. The secondary shunt-

release and undervoltage release mounts to

the immediate left of the trip coil (80.0).

Secondary shunt releases (52T1)

Refer to Figure 19: Construction of

secondary shunt release (shown charged). A

secondary shunt-release (extra-trip coil)

(3AX1101) is used for electrical opening of

the circuit breaker by protective relays or

manual control devices when more than

one trip coil is required. The second trip coil

is generally connected to a separate

auxiliary supply (dc or ac) from the control

supply used for the normal trip coil. An

alternate configuration is available where an

additional coil identical to the primary coil is

used for three-cycle applications.

Undervoltage releases

Refer to Figure 20: Latch details (shown

charged) and Figure 21: Undervoltage lock/

operate selection on page 34. The

undervoltage release (3AX1103) is used for

continuous monitoring of the tripping

supply voltage. If this supply voltage falls

excessively, the undervoltage release will

provide for automatic tripping of the circuit

breaker. The undervoltage device may be

used for manual or relay tripping by

employing a contact in series with

undervoltage device holding coil. Relay

tripping may also be achieved by employing

a normally open contact in parallel with the

holding coil.

Figure 19: Construction of secondary shunt release (shown charged)

23.0

13.0

9.0

15.0

5.0

3.0

11.0

21.0

25.0 27.0

7.0

31.0

33.0

1.0

Figure 20: Latch details (shown charged)

23.0

25.0

29.0

21.0

27.0

Locked/unlocked selection screw (undervoltage release only)

If this scheme is used, a resistor must be

provided to limit current when the normally

open contact is closed. Secondary shunt and

undervoltage releases are available for all

standard ANSI/IEEE control voltages.