39

Place the circuit breaker in the CLOSE

BLOCKED position by moving the manual

open handle on the right side of the circuit

breaker (refer to Figure 8: Relay and control

and operator compartments for type SDV7-

MA circuit breaker with magnetic-actuator

operator on page 30.)

Checks of primary power path

The primary power path consists of the three

vacuum interrupters, six bus connections to

the bushings and the roof-mounted bushings.

These components must be checked for

cleanliness and condition. The vacuum

interrupters must also be checked for vacuum

integrity.

Check torque of the bolts that secure the roof

bushings to the top plate of the circuit

breaker. Torque should be in the range of 20-

25 ft-lbs (27-34 Nm).

If a bushing has been removed or is being

replaced, tighten bushing mounting bolts in a

cross pattern, progressively increasing torque

from one-third to two-thirds to full torque.

Use anti-seize compound (Loctite* 77164 or

77124 nickel anti-seize) on the threads of

the roof studs to facilitate future removal of

a bushing should it become necessary.

For connections between the bottom of the

bushing and the bus bar, torque the

1

/

2

-13

SAE grade 5 steel hardware to 50-75 ft-lbs

(80-102 Nm).

For connections between the bus bars and

the pole heads of the operator, torque M12

x 1.75 grade 8 bolts to 52 ft-lbs (70 Nm).

Some test engineers prefer to perform the

contact erosion check during the manual

spring charging check of the stored-energy

operator, since charging of the springs is

necessary to place the contacts in the closed

position.

Also, the vacuum integrity check is usually

performed in conjunction with the High

Potential tests. These instructions follow the

recommendation that these tests contact

erosion/manual spring charging check, and

vacuum integrity/high-potential tests) will be

combined as described.

Cleanliness check

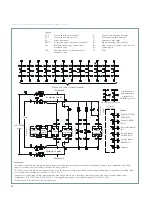

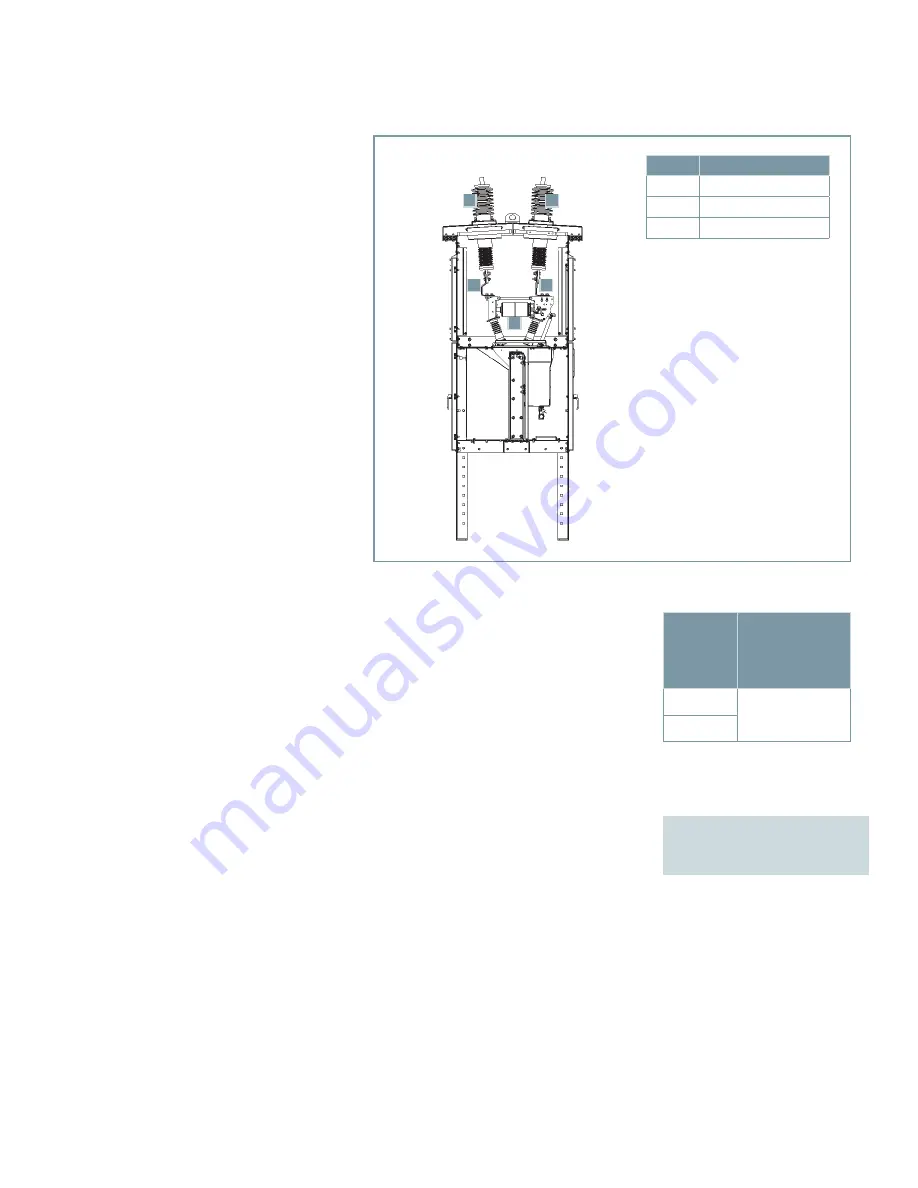

Figure 9 is a side view of the type SDV7

distribution circuit breaker showing the

vacuum interrupter, bus connections and roof

bushings.

All of these components must be cleaned and

free of dirt or any foreign objects. Use a dry

lint-free cloth. For stubborn dirt, use a clean

cloth saturated with denatured alcohol.

Also inspect the bus work for any evidence of

loose bolts, bushings for any evidence of

damage, and flexible connectors for tightness

and absence of mechanical damage, burning,

or pitting.

Checks of the stored-energy operator

mechanism

The stored-energy operator checks are

divided into mechanical and electrical checks

for simplicity and better organization. The

first series of checks determine if the basic

mechanism is clean, lubricated and operates

smoothly without control power. The contact

erosion check of the vacuum interrupter is

also performed during these tasks.

Maintenance and lubrication

Table 5 presents the recommended

maintenance intervals for the type SDV7

distribution circuit breakers. These intervals

assume that the circuit breaker is operated

under “usual service conditions” as discussed

in ANSI/IEEE C37.04, section 4, and

elaborated in ANSI/IEEE C37.010, section 4.

The maintenance and lubrication interval is

the lesser of the number of closing operations

or the time interval since last maintenance.

Circuit

breaker

type

Number of years/

closing operations

(whichever comes

first)

SDV7-SE

Five-years/

10,000 operation

SDV7-MA

Figure 9: Side view of type SDV7 distribution circuit breaker

Table 5: Maintenance and

lubrication intervals

1-3-5

2-4-6

Item

Description

A

Bushings

B

Bus

C

Vacuum interrupter

A

A

B

B

C

* Loctite is a registered

trademark of Henkel

Corporation.

Summary of Contents for SDV7

Page 54: ...54 Table 16 Remarks ...

Page 55: ...55 Table 16 Remarks continued ...