5. Clean dust from the detector cover, foam screen, sens-

ing chamber and labyrinth using a brush, or by blowing

with compressed air.

Do not use a compressed air supply that may

contain an oil residue.

Do not remove or loosen the two screws on

the rear of the detector, or calibration data will

be lost.

The insect screen and labyrinth may be

replaced with new parts, rather than be

cleaned. Contact Siemens Building Technolo-

gies, Inc. Product Service to order Detector

Maintenance Kit, Model DMK-11. Do not

disconnect the thermal wires from the

detector.

6. Reassemble the detector by reversing the steps used for

disassembly, and reinstall in its base.

7.

Test the detector. (See Detector Testing section of this

instruction.)

8. When all service has been completed, notify personnel

(See Step 1) that system service has been completed.

No field repair of the detectors should be

attempted. The detectors are factory repair-

able only.

ELECTRICAL RATINGS

CX-2 (FDLC) Addressable Device Loop ratings:

Voltage: 18-31V (pulsing)

Current: 1mA

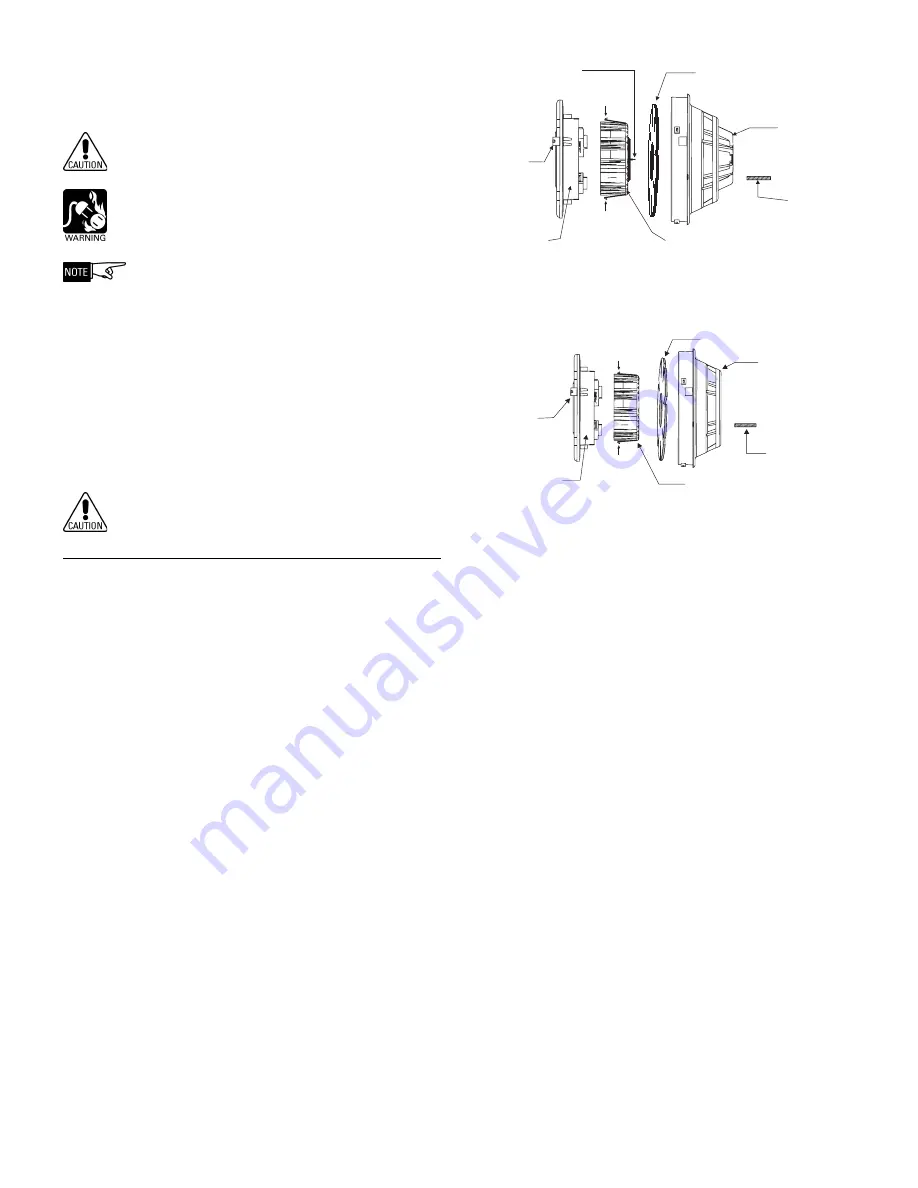

Figure 4

Disassembling of SFP-11 Photochamber

P/N 315-033290C-7

Siemens Building Technologies, Ltd.

2 Kenview Boulevard

Brampton, Ontario L6T 5E4 Canada

COVER

LABYRINTH

LOCKING

SCREW

(OPTIONAL)

COVER TAB

SENSING

CHAMBER

RELEASE

AXIS

RELEASE

AXIS

(MATCHES AXIS

OF REAR SCREWS)

THERMAL

FOAM

SCREEN

Figure 5

Disassembling of SFPO-11 Photochamber

COVER

FOAM SCREEN

LABYRINTH

SENSING

CHAMBER

RELEASE

AXIS

RELEASE

AXIS

(MATCHES AXIS

OF REAR SCREWS)

LOCKING

SCREW

(OPTIONAL)

COVER TAB